Environmentally Friendly Products

Manufacturing Philosophy

◆Efforts to Maximize the Environmental Contribution of Our Products

The NSK Group strives to contribute to a safer, smoother society and help protect the global environment, as indicated in its Mission Statement. To achieve this, NSK is developing environmentally friendly products and technologies in line with our "Basic Policy for the Development of Environmentally Friendly Products" by making full use of our Four Core Technologies plus One: tribology, materials, numerical simulation and mechatronics, plus manufacturing engineering.

While many automobiles and industrial machines worldwide consume vast amounts of energy by operating for extended periods, NSK's products aim to reduce this energy consumption to the greatest extent possible through downsizing, weight reduction, and low torque. Furthermore, they are used in renewable energy facilities such as wind turbines, contributing to their spread. On the other hand, because the production and processing of steel, which is a key material for NSK products, requires many resources, NSK promotes waste reduction and efficient use of resources through product life-span extension and recycling. Through these efforts, NSK is working to reduce CO2 emissions throughout the entire product life cycle.

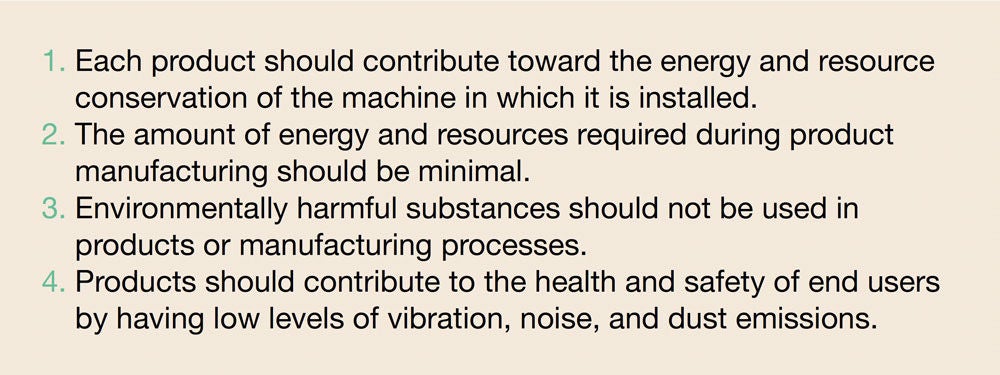

◆Basic Policy for the Development of Environmentally Friendly Products

◆Verification Requirements and Assessment Items for Each Stage of the Product Lifecycle

NSK assesses all products throughout their entire lifecycle according to the items listed in the table below, and strives to both maximize its products’ environmental contribution, and minimize their environmental impact by reducing the amount of steel, water, and other resources used and lowering GHG emissions.

| Lifecycle | NSK Initiatives (Contributing to resource and energy conservation, safety, and cleanliness) |

|---|---|

| Procurement of raw materials |

|

Production |

|

| Transport |

|

| Use |

|

| Disposal/recycling |

|

* Environmentally harmful substances: Taking national and regional laws and regulations, as well as industry guidelines, into account, NSK defines environmentally harmful substances as chemical substances that are, or could potentially be, harmful to human health, ecosystems, and/or environmental conservation, including toxic substances, ozone-depleting substances, and substances that pollute air, water, soil, or groundwater. NSK properly manages these substances, including by prohibiting their use. For more information, see “Reducing Use of Environmentally Harmful Substances.”

Targets and Performance

◆Mid-Term Management Plan 2026 (MTP2026) Targets, with Targets and Performance for Each Fiscal Year

| MTP2026 Targets | FY2024 Targets | FY2024 Performance | FY2025 Targets | |

|---|---|---|---|---|

| Creating environmentally friendly products | Create environmentally friendly products with a Neco score of 1.2 or higher (ongoing) | Continue with new developments (Develop 1 or more environmentally friendly products) | Developed 7 environmentally friendly products | Develop 3 environmentally friendly products |

| Avoid at least 3 million t-CO2 emissions during the use of NSK products | 2.47 million t-CO2 | 2.32 million t-CO2 | 2.51 million t-CO2 | |

Indicators for NSK Environmentally Friendly Products

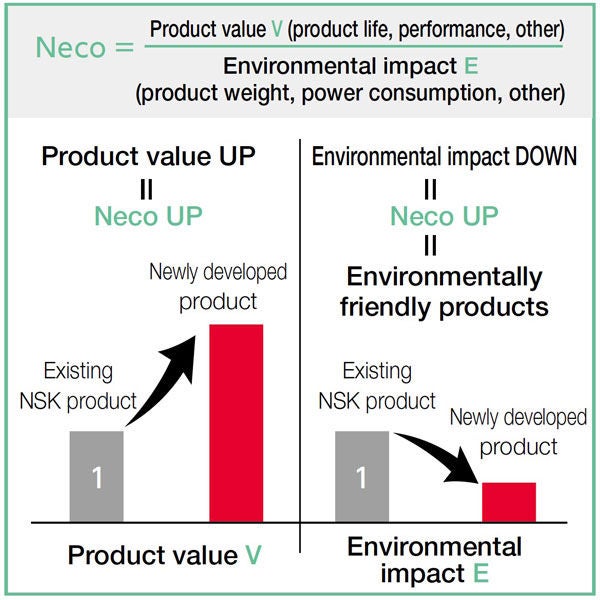

NSK has defined and operates its own indicators showing the environmental contribution of its products: the NSK Eco-efficiency Indicator (Neco), and avoided CO2 emissions. The Neco is used to assess a product’s environmental contribution based on such factors as service life. The NSK avoided CO2 emissions index assesses both avoided emissions resulting from these factors (direct contributions) and indirectly avoided emissions from the use of wind power, etc. (indirect contributions).

These indicators quantify the extent of a product’s contribution, and NSK uses them to develop products that contribute to the environment by, for example, reducing CO2 emissions.

◆NSK Eco-efficiency Indicator (Neco)

NSK has introduced the Neco score as a unique quantitative metric to comprehensively evaluate environmental contributions at the product development stage.

The Neco score is a numerical value obtained by dividing the product value V by the environmental impact E, which represents in numerical form the degree of improvement over the conventional product with a value of 1. The numerator, product value V, represents factors that assess performance, such as service life, accuracy, and maximum rotation speed. The denominator, environmental impact E, represents factors that assess environmental impact, such as product weight, power consumption, and friction loss. The greater the product value V and the smaller the environmental impact E, the greater the Neco score, indicating a more environmentally friendly product.

In assessing newly developed bearings, for example, the longer the bearing’s service life is, when compared to existing products, the better its high-speed rotation, the lighter and more compact the bearing is, and the lower the friction loss, the higher its Neco value will be, indicating a more environmentally friendly product. In developing new products, NSK aims for a Neco score of 1.2 or higher.

◆Avoided CO₂ Emissions

NSK’s initiatives to avoid CO2 emissions in the “utilize” stage fall into two categories: direct contributions and indirect contributions. In FY2024, total avoided emissions in both categories were 2.32 million tons. NSK will continue to strengthen these initiatives with the aim of delivering over 3 million tons of avoided emissions by FY2026, thereby contributing to the reduction of CO2 emissions across society as a whole.

Concepts for Products Helping to Avoid CO₂ Emissions at the “Utilize” stage

| Category | Contribution concept | Examples of contributions to CO₂ reduction |

|---|---|---|

| Direct Contributions | Direct contributions to CO₂ emissions reduction through individual NSK product performance |

|

| Indirect Contributions | Indirect contributions through CO₂ emissions avoided by incorporating NSK products into customer equipment and facilities |

|

◆Direct Contributions

In this area, NSK products effectively contribute to the reduction of CO2 emissions by improving the performance of existing products, such as curbing friction loss in bearings, to directly reduce energy loss in the customer machinery in which they are incorporated.

This contribution is calculated using the formula shown below.

CO2 emissions avoided (product basis) = ΔPCO2 × Annual uptime × Duration of use × Product sales volume

ΔPCO2: CO2 emissions avoided per unit of time product is used (CO2/hour)

Annual uptime: Time a product is in operation per year (hours/year)

Duration of use: How long a product is used (years)

Product sales volume: Sales volume of the product in the fiscal year

Note: The Japan Bearing Industry Association formulated guidelines.

Example: Low Friction Hub Unit Bearings

As hub unit bearings are often used in harsh environments in the field, they are equipped with seals to prevent mud and water from getting inside. Although these bearings are expected to improve efficiency by reducing friction, focusing on achieving low friction alone can damage the reliability of the bearings during use.

By optimizing internal bearing design, selecting the optimal grease, and developing low friction seals, NSK has developed a low friction hub unit bearing that delivers 40% lower friction, while still maintaining the field reliability required.

For more information, click here.

Example: MT-Frix™ low-friction ball screws

When a ball screw is driven, it generates heat due to dynamic friction torque, and the screw shaft undergoes thermal expansion, which in turn reduces the positioning accuracy. In order to prevent accuracy loss due to heat generation, forced cooling (cooling the generated heat with an auxiliary device, etc.) may be used, but extra energy is consumed when a cooling device is employed. Therefore, in order to achieve both high precision and energy savings, it is necessary to reduce the dynamic friction torque itself.

However, with conventional technology, when the dynamic friction torque is reduced, the rigidity also declines, making the nut more likely to experience displacement, which in turn can result in the problem of reduced machining accuracy. Therefore, reducing dynamic friction torque while maintaining rigidity is needed.

NSK has leveraged its analytical technology to elucidate the precise conditions of contact between the ball and groove inside its ball screws. The findings allowed NSK to optimize the internal specifications, and the result is the newly developed MT-Frix™, a low-friction ball screw with lower dynamic friction torque but the same rigidity and size.

For more information about this product, click here.

◆Indirect Contributions

In this area, NSK products such as bearings for wind turbines and ball screws for electric injection molding machines (with motorized hydraulics) that are used to manufacture plastic products contribute indirectly when employed in customer machinery. Guidelines have been established based on the disclosed contribution rate of bearings in the wind power generation field. The contribution is calculated using the formula below.

CO2 emissions avoided (equipment basis) = ΔPCO2 × Annual uptime × Duration of use × Contribution rate × Penetration (sales volume)

ΔPCO2: CO2 emissions avoided per unit of time equipment is used (CO2/hour)

Annual uptime: Time that equipment is in operation per year (hours/year)

Duration of use: How long equipment is used (years)

Contribution rate: Rate of contribution of NSK products to the equipment (%)

Product penetration (sales volume): Penetration (sales volume) of the product in the fiscal year

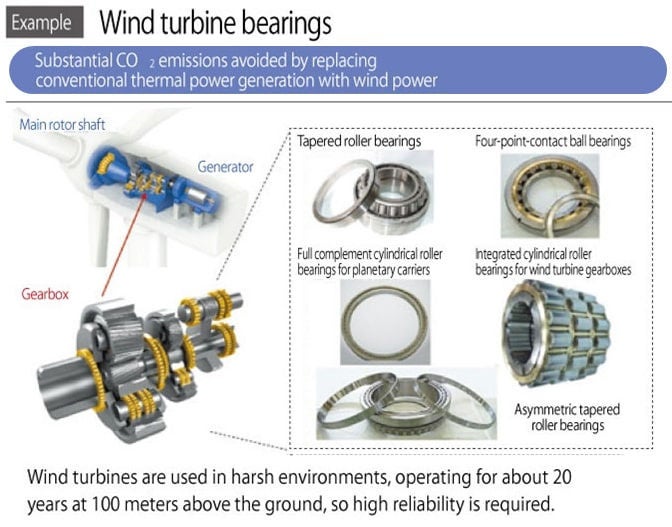

Example: Bearings for Wind Turbines

Since replacing turbine parts is difficult, bearings for wind turbines are required to operate for 20 years and must therefore be exceptionally reliable. NSK provides high-quality bearings used in the gearbox. They help determine the performance of the wind turbine and contribute to the spread of renewable energy. Thanks to NSK’s advanced computer-based numerical simulations, extensive expertise in materials and heat treatment, and technologies for testing and evaluating full-size bearings, NSK bearings deliver world-class performance.

◆CO₂ Emission Reduction through Services

In addition to selling products, NSK provides technical services such as maintenance and condition monitoring technology, aiming to reduce CO2 emissions throughout the entire product life cycle - from product restoration to disposal.

Example: Condition Monitoring Solutions and Reconditioning

Condition monitoring solutions measure and analyze the vibrations of rotating and linear motion mechanisms inside equipment to diagnose the product’s condition and life span.

This contributes to improved machine reliability and extended product life. In addition, reconditioning enables product repair and reuse.

◆Contributing to a Decarbonized Society

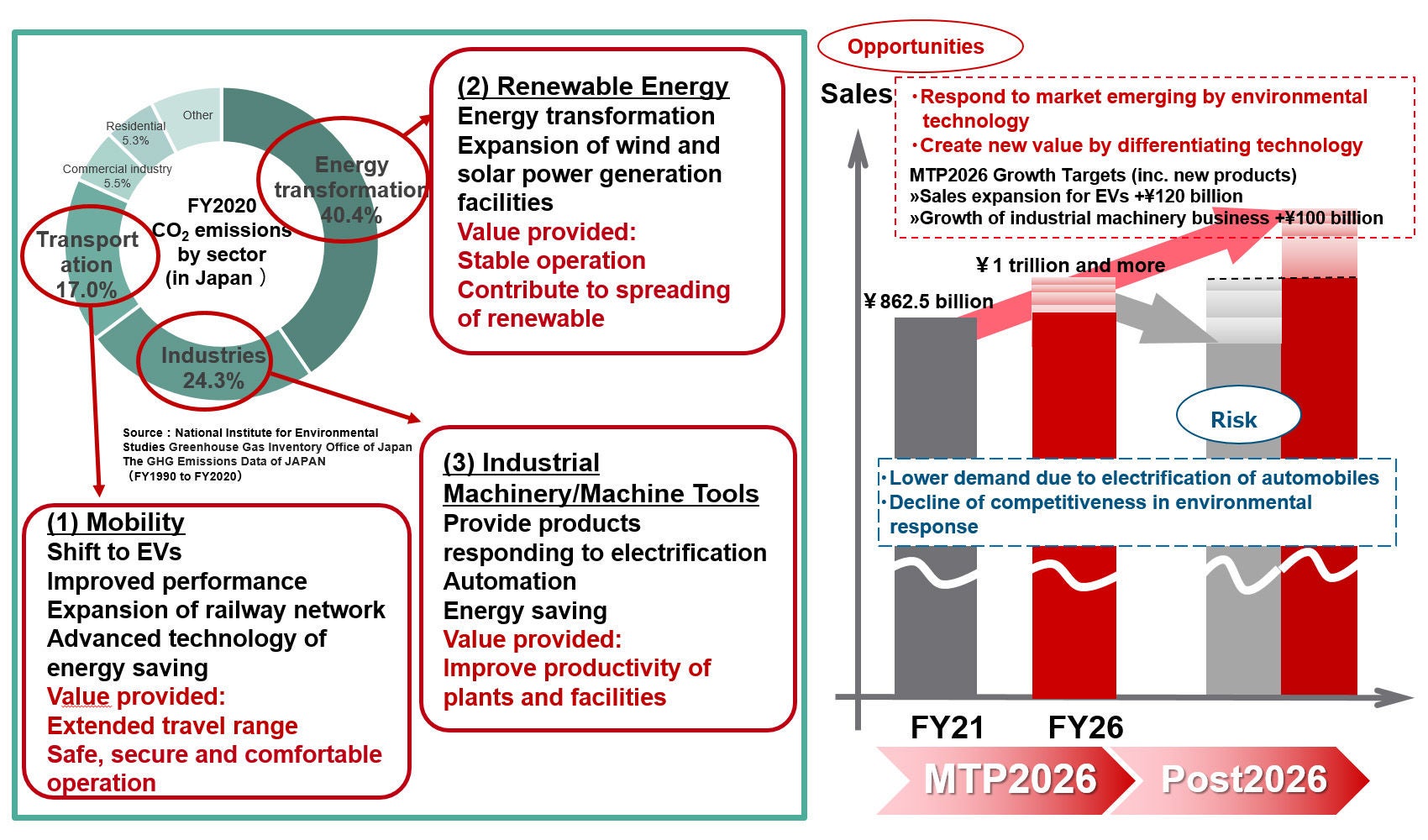

NSK recognizes that contributing to a decarbonized society is an opportunity for profitable growth. In particular, NSK is focusing on markets that are expected to see growth in the fields of mobility, renewable energy, and industrial machinery/machine tools. NSK aims to meet society’s needs and achieve sustainable growth by developing products that leverage NSK’s strengths in areas like precision bearings, precision ball screws, and automotive components for electric vehicles in order to expand its sales in highly profitable markets.

Example: Environmental Contribution through Automotive Electrification

Automotive electrification is indispensable to achieving carbon neutrality. Under MTP2026, NSK sets a sales promotion plan for electric vehicle components and will seek to differentiate its technology and expand its business by offering a new product, ball screws for electro-hydraulic brake systems.