Steel & Metals

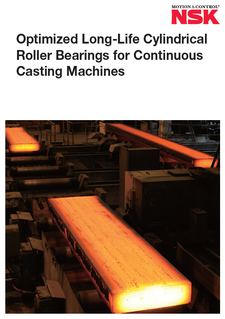

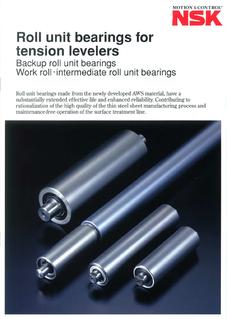

Bearings play a vital role in steelmaking—from conveyors in the storage yard to the mills and casters in metalworking, rolling, and refining processes.

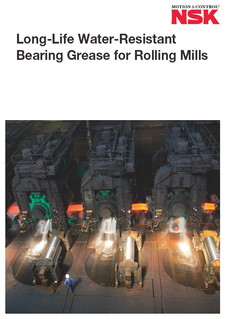

Steelmaking facilities present a uniquely tough environment for bearings. Besides exposure to metal dust, water, and heat, bearings face heavy loads and intense vibration, both extremely low and high speeds, and rapid acceleration/deceleration.

To secure stable operation and higher productivity in this challenging environment, NSK employs advanced bearing technologies based on extensive R&D from many different angles, including design, materials, and lubrication.

We have decades of experience working closely with some of the biggest steelmakers globally to achieve top-class reliability and long life in steel industry applications. NSK offers a comprehensive lineup for the steel & metals industry–from bearings standardized by ISO to specialized, NSK-exclusive high-performance products.

Recognizing the modern needs of the dynamic steel industry, NSK provides value-added solutions with lower environmental impact.