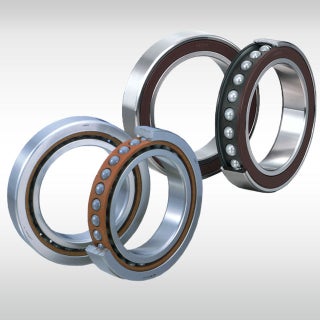

Super Precision Angular Contact Ball Bearings

Overview

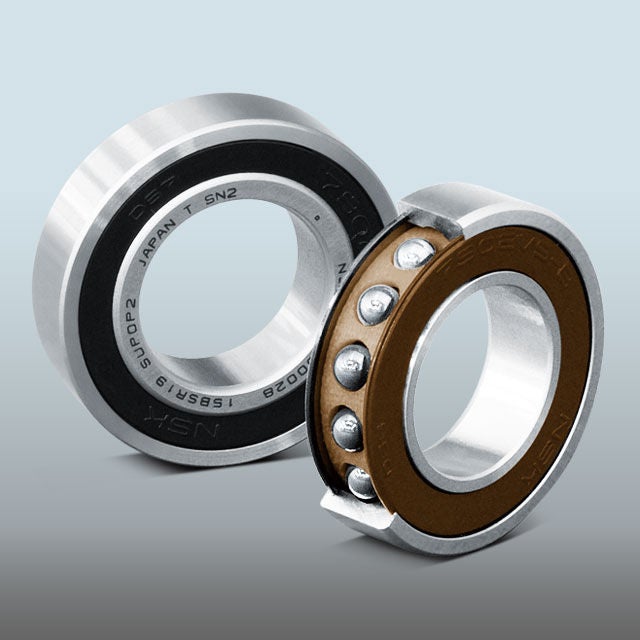

NSK offers a wide lineup of super precision angular contact ball bearings to provide optimal specifications for your application.

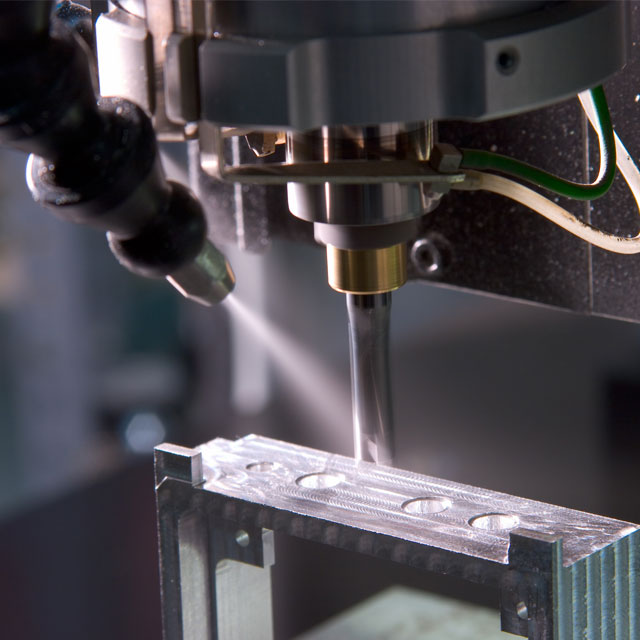

Our bearings provide the perfect solution for equipment requiring high running accuracy or high rotational speed, such as the main spindles of machine tools.

Lineup Highlights

- Standard bearings that conform to ISO standards and specialized series for machine tools

- Sealed bearings with prepacked grease

- A range of NSKROBUST™ high-performance bearings for both high rigidity and ultra-high speeds

Product List

FAQs

Catalogs

Search our full listing of catalogs for more details.

2D/3D CAD Data

Download 2D & 3D CAD model files and spec. sheets for NSK products through PARTcommunity.

This free service is provided by CADENAS GmbH.