Needle Roller Bearings

Overview

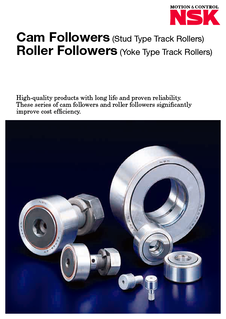

Needle roller bearings (sometimes called “needle bearings”) use long and narrow cylindrical rollers that sometimes exceed JIS/ISO size ranges. They are categorized as thrust or radial bearings based on which load direction they support. Radial types include drawn-cup and solid types, as well as application-specific track rollers (cam and roller followers). Thrust needle and thrust roller bearings respond to axial load needs.

Product List

FAQs

Catalogs

Search our full listing of catalogs for more details.

2D/3D CAD Data

Download 2D & 3D CAD model files and spec. sheets for NSK products through PARTcommunity.

This free service is provided by CADENAS GmbH.