9—Lubrication

Up to 50% of the energy used to operate equipment is lost to friction. Lubricants are crucial in combating this energy loss, and a variety of lubrication methods exist to ensure proper lubrication in all kinds of machines.

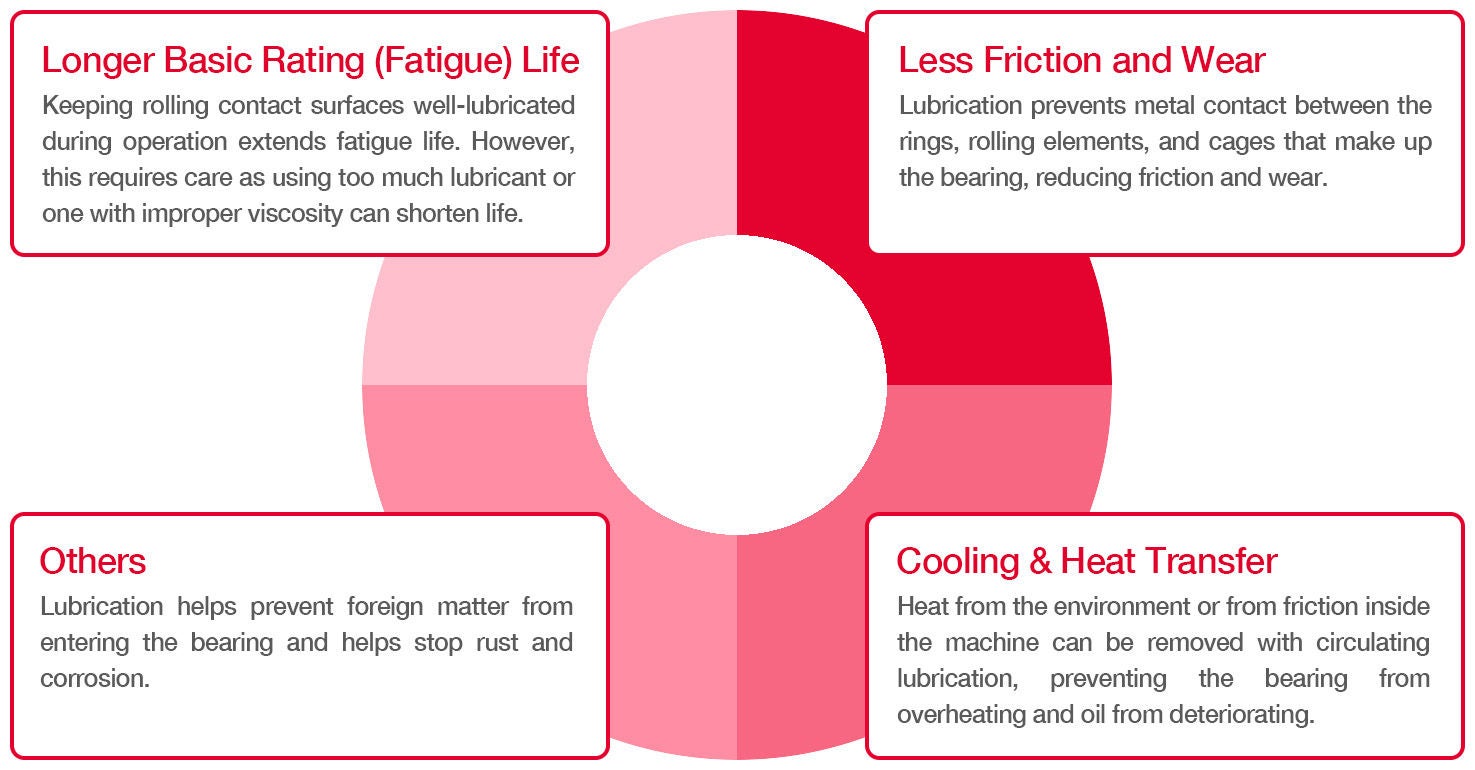

Purpose of Lubrication

Rolling bearings are lubricated to reduce internal friction, lower wear, and stop components from seizing. The benefits of lubrication are shown below:

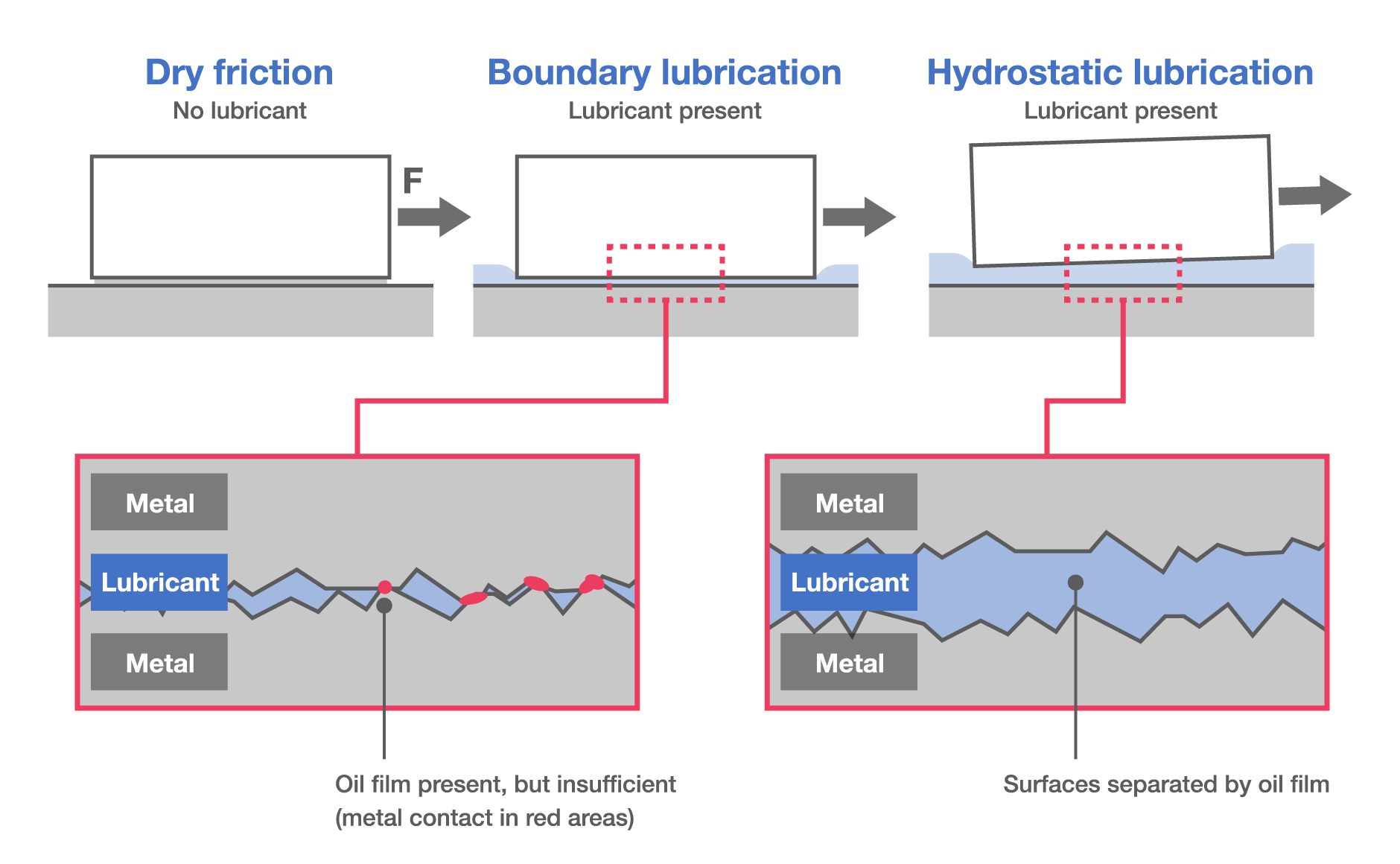

Principles of Lubrication

Lubrication aims to prevent direct contact between the surfaces of two objects in relative motion.

Grease Vs. Oil

In terms of pure lubricating capacity, oil is best. However, grease is a low-cost alternative that allows for a simpler structure around bearings.

Table Key: ◯:Good, ×:Poor

| Item | Grease | Oil |

|---|---|---|

| Housing structure/ seal configuration | ◯:Can be simple. | ✕: Somewhat complicated, requires careful maintenance |

| Rotating speed | ✕: Supports 65 to 80% the limiting speeds of oil lubrication | ◯:Supports higher speeds than grease |

| Cooling effect | ✕:None | ◯:Can effectively dissipate heat (circulating lubrication) |

| Flowability | ✕:Poor | ◯:Very good |

| Full replacement | ✕:Somewhat complex | ◯:Relatively easy |

| Contaminant filtration | ✕:Somewhat complex | ◯:Easy |

| External contamination from leaks | ◯:Surroundings seldom contaminated by leakage. | ✕:Often leaks without proper countermeasureres. Not suitable if external contamination must be avoided. |