4—Dynamic Load Ratings and Fatigue Life

Load ratings and fatigue life are crucial concepts in bearing reliability. A bearing’s basic dynamic load rating expresses the constant load that a rolling bearing with a stationary outer ring can support under inner ring rotation to one million revolutions with a certain level of reliability.

The outer and inner ring raceways and rolling elements repeatedly come under load as they rotate, causing material fatigue that eventually results in scale-like damage called flaking (spalling). Rolling fatigue life indicates the total number of revolutions before this damage appears and is often abbreviated as “bearing life” in technical contexts.

Bearing Life

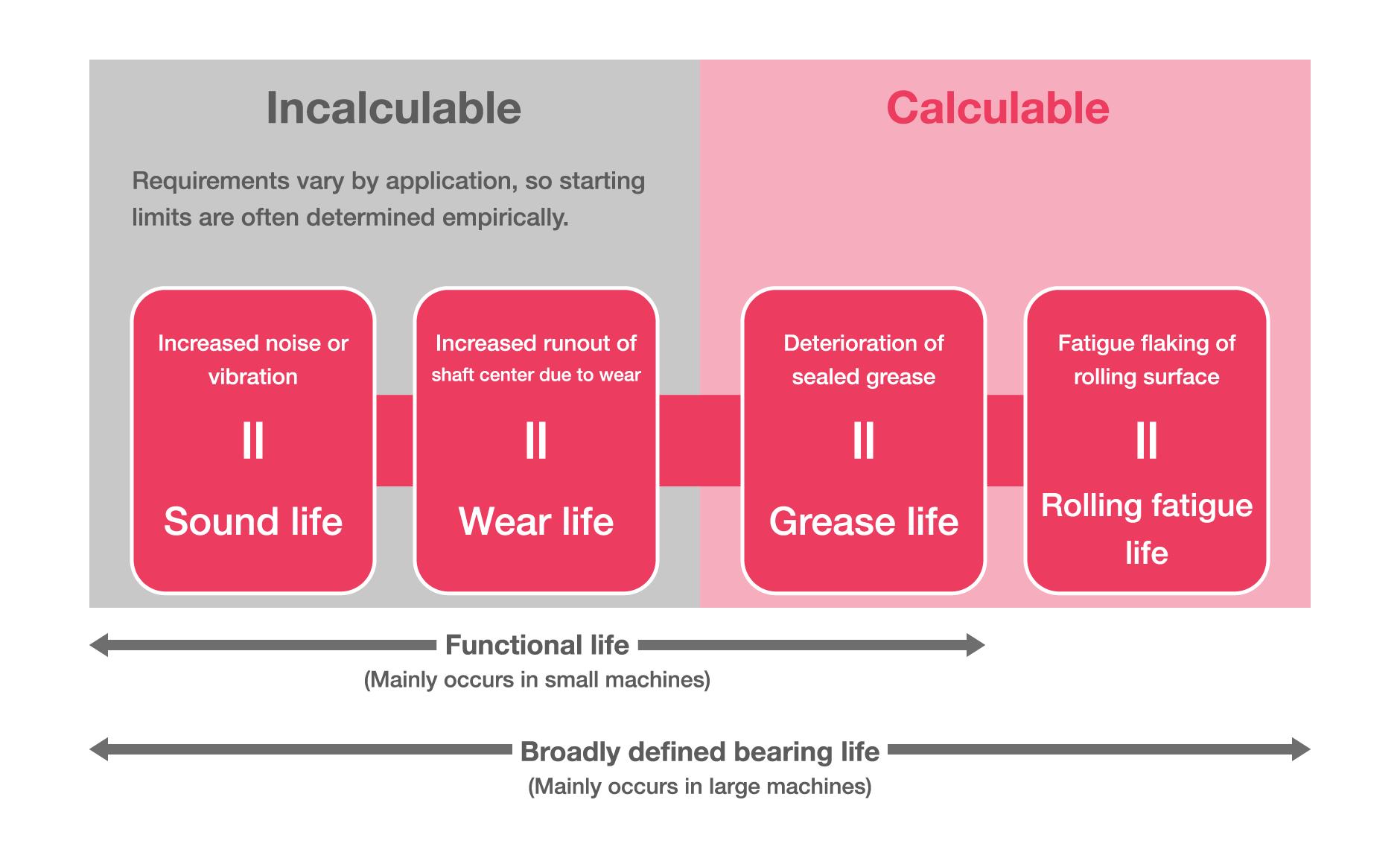

In broad terms, bearing life expresses how long bearings can operate while satisfying required functions, meaning bearing life can be thought about in various ways. For example, a bearing may need to be replaced when noise, vibration, or torque rise or when bearing temperatures become too hot for an application. Bearing life can be estimated from experience or calculations.

Rolling Fatigue Life

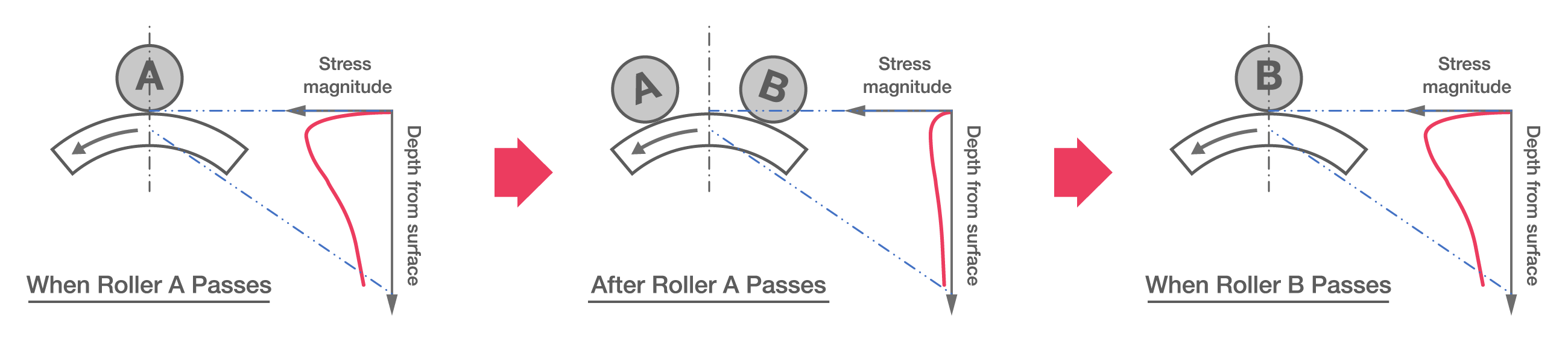

As the bearing rotates under load, the raceways of the inner and outer rings and the rolling surfaces of the rolling elements are subjected to cyclic loading that causes internal stress. Eventually, material fatigue causes scale-like damage called flaking to appear on the raceways or rolling surfaces (mainly on the inner ring raceway). The total number of revolutions before this damage occurs is called the rolling fatigue life.

Example of inner ring flaking

Variation in Rolling Fatigue Life

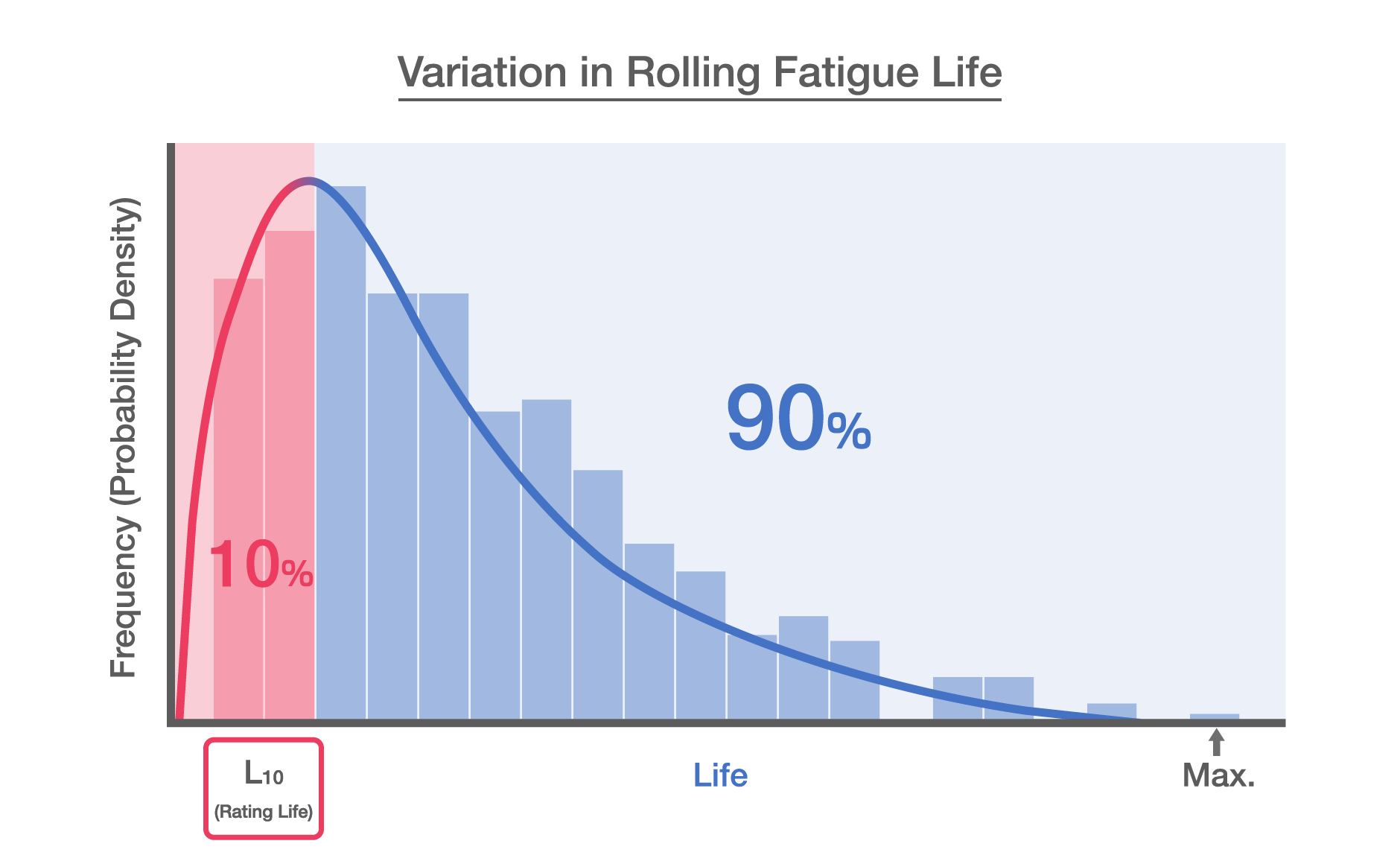

Rolling fatigue life varies considerably, even when bearings with the same dimensions, structure, materials, heat treatment, and processing are operated under the same conditions. This is because material fatigue is inherently variable, as illustrated below. Therefore, variation in life is treated as a statistical phenomenon in the definition of basic rating life.

Basic Rating Life L10

The basic rating life (L10) refers to how long identical bearings can rotate under the same conditions until flaking occurs on 10% of them from rolling fatigue. It indicates life with a statistical reliability of 90% and may be given in hours or the number of revolutions.

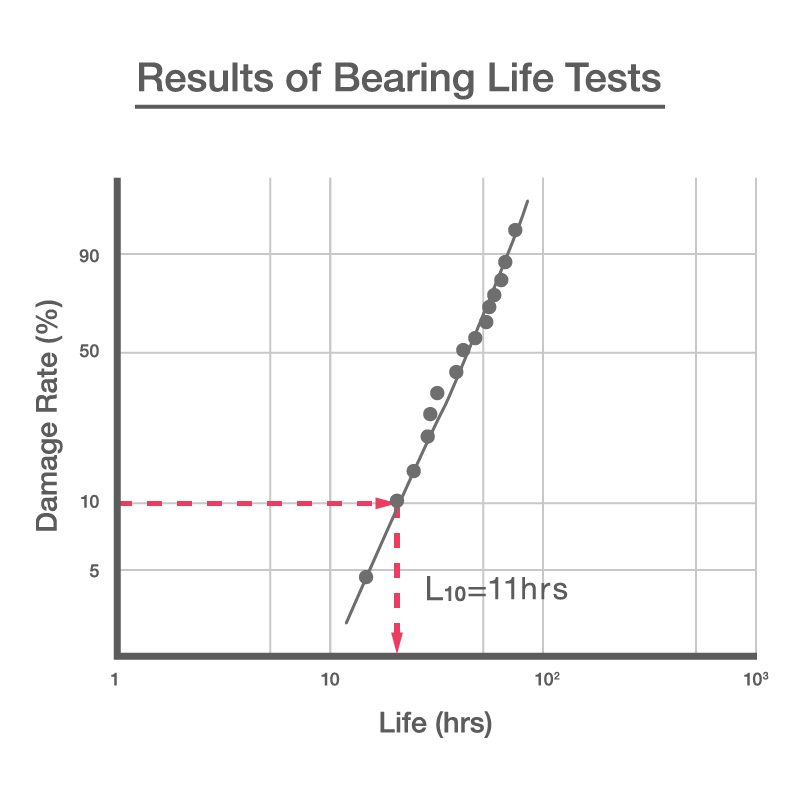

- The Weibull plot here visualizes damage (worsening reliability) over time using a linear approximation of life test results.

- By plotting the results of reliability tests on a Weibull plot, we can confirm that bearing life follows a Weibull distribution*. The plot shows time on the X-axis with a log10 scale and cumulative failure (damaged bearings) on the Y-axis.

*A method to describe a statistical distribution of probability, used often in reliability engineering to visualize a product’s strength over time.

Basic Dynamic Load Rating

Definition:

The constant load that a bearing can endure for a rating life of one million rotations under inner ring rotation with a stationary outer ring to a set reliability (typically in L10 terms for a 10% failure rate/90% reliability).

Point contact

Suitable for light loads, low torque, and high speed

Linear contact

Suitable for heavy loads and low speeds

Basic Life Calculation Formula:

Ball bearings: L10 = (C/P)3

Roller bearings: L10 = (C/P)10/3

where

L10: Basic life rating (x106 revolutions)

C: Basic dynamic load rating (N)

P: Bearing load (dynamic equivalent load) (N)

For radial bearings, C is written Cr, For thrust bearings, C is written Ca

For radial bearings, P is written Pr, For thrust bearings, P is written Pa.

Note that characters may lack mathematical formatting (italics, subscripts, etc) in some descriptions.

Load and Life

As established above, bearing life reflects the relation between a bearing's basic dynamic load rating and load. However, for convenience, basic rating fatigue life is often expressed in hours and with the following relationship incorporating rotational speed.

Ball bearings

Roller bearings

where

L10: Basic life rating (x106 revolutions)

C: Basic dynamic load rating (N)

P: Bearing load (dynamic equivalent load) (N)

n: Bearing rotational speed

A guideline from this relationship holds that:

When load is halved:

life for ball bearings becomes 8x longer

and life for roller bearings becomes 10x times longer.