10.2—Dismounting

When dismounting bearings for equipment maintenance, care must be taken to avoid deforming or damaging the bearing mounting area. Furthermore, bearings that will be reused must be removed with extra care.

Dismounting Precautions

Avoiding Damage

If bearings or mounted components will be reused after dismounting or if dismounting for inspection, they should be removed with the same care taken during mounting to avoid damage.

Design Considerations

It is often difficult to remove mounted bearings, especially those with tight fits.

Consider the ease of dismounting in the structure around the bearings at the design stage, and create dismounting jigs as necessary.

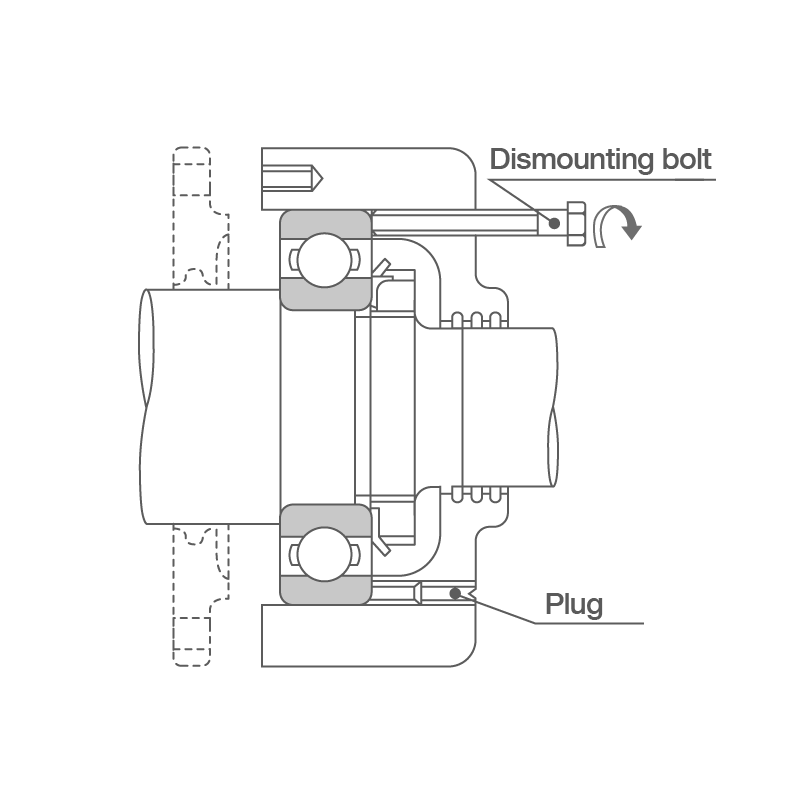

Dismounting Outer Rings

- If an outer ring with a tight fit will need to be dismounted, the housing should be designed with several removal slots along its circumference. To dismount, place dismounting bolts into these outer ring push-out slots. Then, tighten the bolts evenly to remove the outer ring.

- These bolt holes should covered with plugs at all other times.

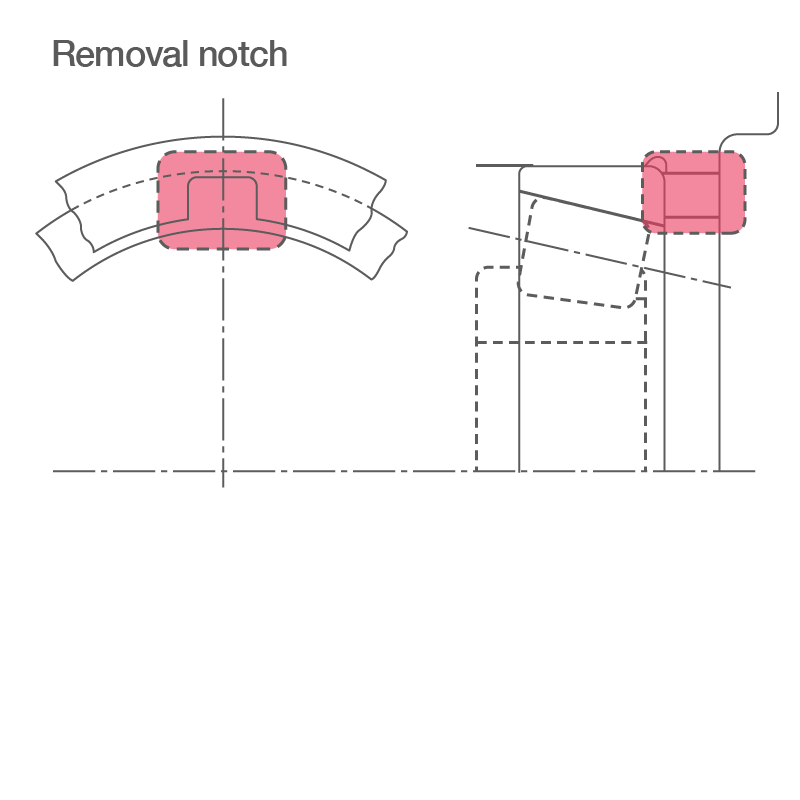

- For separable bearings, such as tapered roller bearings, several notches are provided in the housing shoulder so that the outer ring may be pressed out with a dismounting tool or light tapping.

Dismounting Small Bearings With Cylindrical Bores

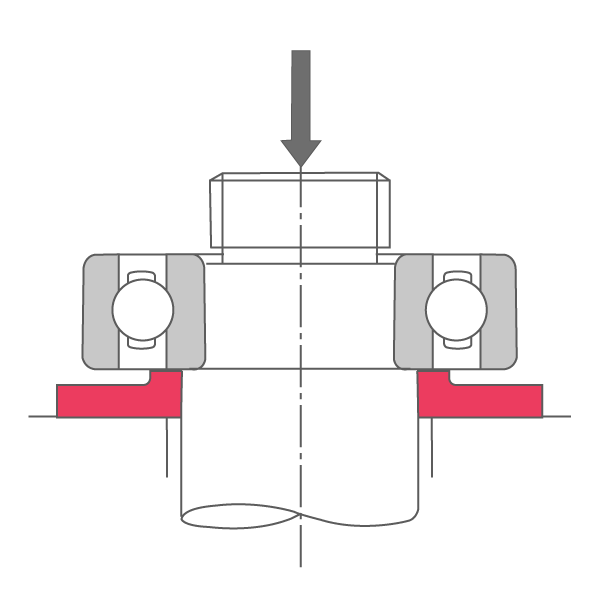

Using a press is the easiest way to remove an inner ring with a cylindrical bore.

When using a press, take extra care to ensure that only the inner ring receives the withdrawal force.

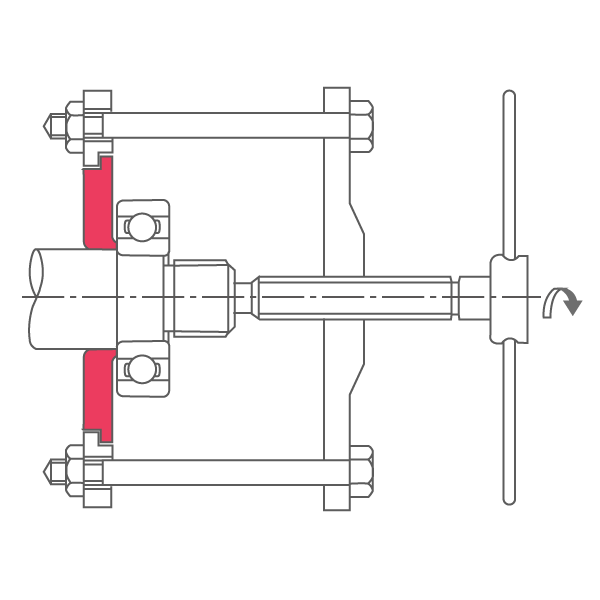

Withdrawal tools (puller jigs) with claws are also used often. In either case, the claws of the tool must fully grip the sides of the inner ring. Therefore, be sure to consider the dimensions of the shaft shoulder carefully during design or machine grooves in the shoulder for the withdrawal tool.

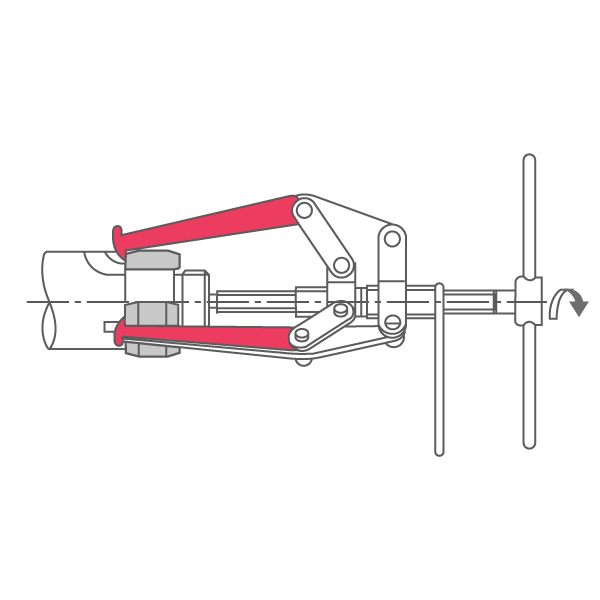

Press

(for dismounting inner ring)

Withdrawal tool

(for dismounting inner ring)

Withdrawal tool (puller)

(for dismounting inner ring)

Dismounting Large Bearings With Cylindrical Bores

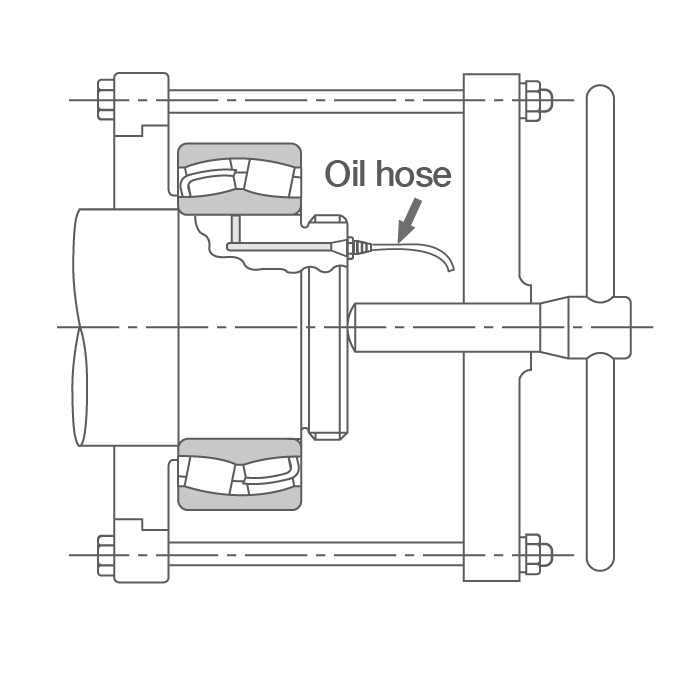

Hydraulic pressure (oil injection) is often used to dismount the inner rings of large bearings with cylindrical bores. Oil is forced through an oil hole in the shaft to create pressure that facilitates removal.

A withdrawal tool may be used along with hydraulic pressure when dismounting wide bearings.

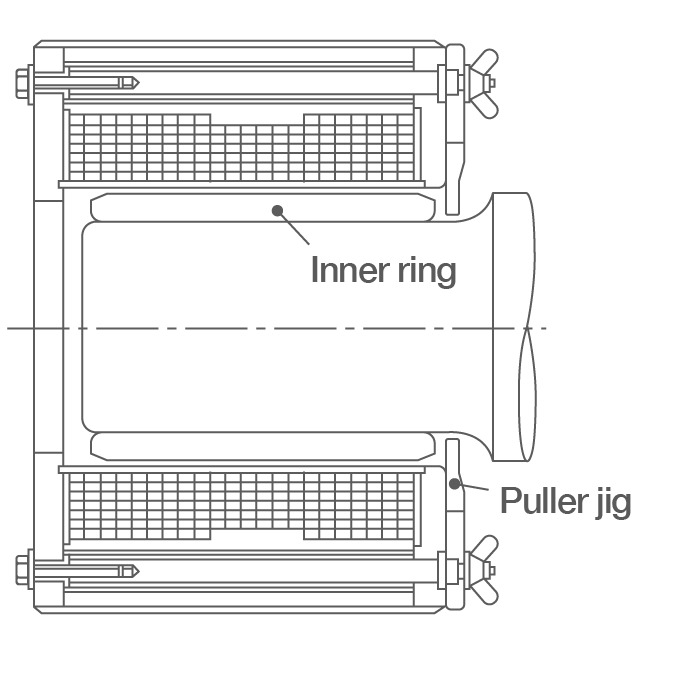

Induction heating can also be used to dismount the inner rings of NU- and NJ-type cylindrical roller bearings.

This method expands the inner ring through a short period of local heating, allowing it to be dismounted.

Induction heating is also convenient when mounting many inner rings of this bearing type at once.

Hydraulic pressure (oil injection)

Induction heater for inner ring

Dismounting Small Bearings With Tapered Bores

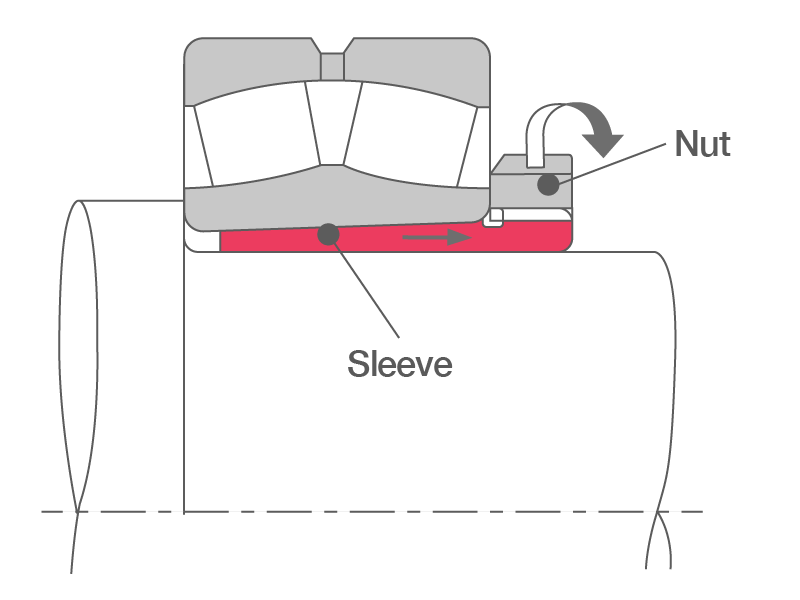

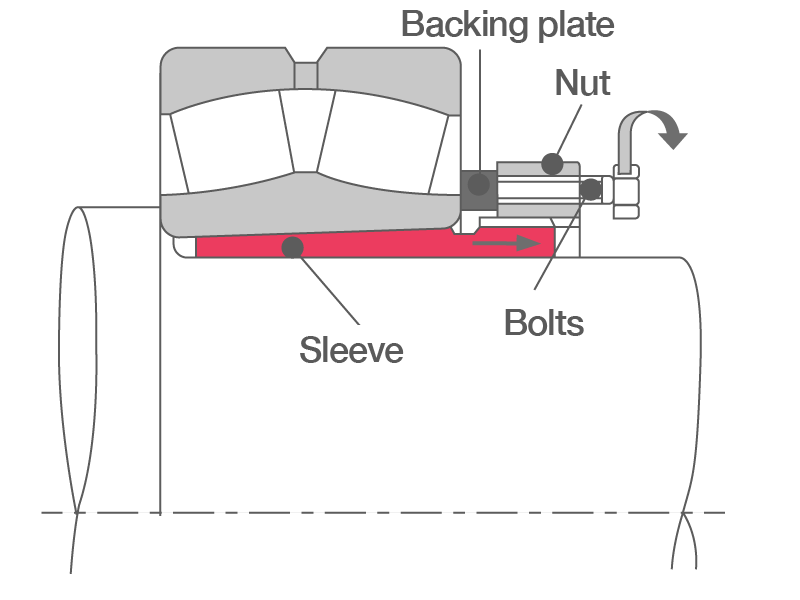

1. Withdrawal Sleeve

Bearings with removable sleeves are dismounted by turning a nut as shown.

If the procedure is difficult, the sleeve can be removed by making bolt holes in the nut at several spots along its circumference and turning these bolts as shown.

Withdrawal sleeve (1)

Withdrawal sleeve (2)

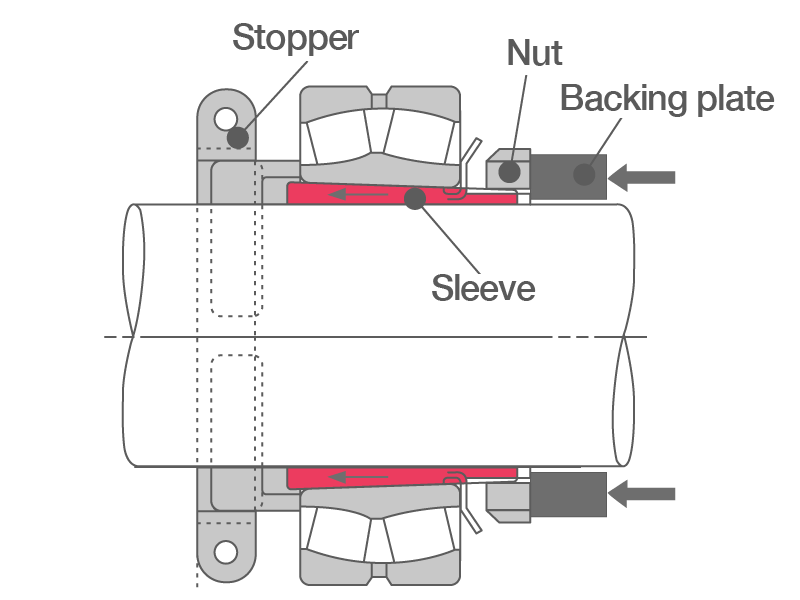

2. Adapter Sleeve

Adapter sleeves are used to dismount relatively small bearings.

After securing the inner ring with a stopper (clamp) and loosening the nut several turns, the sleeve can be removed by hitting it with a hammer or dismounting tool.

Removal of adapter with a stopper

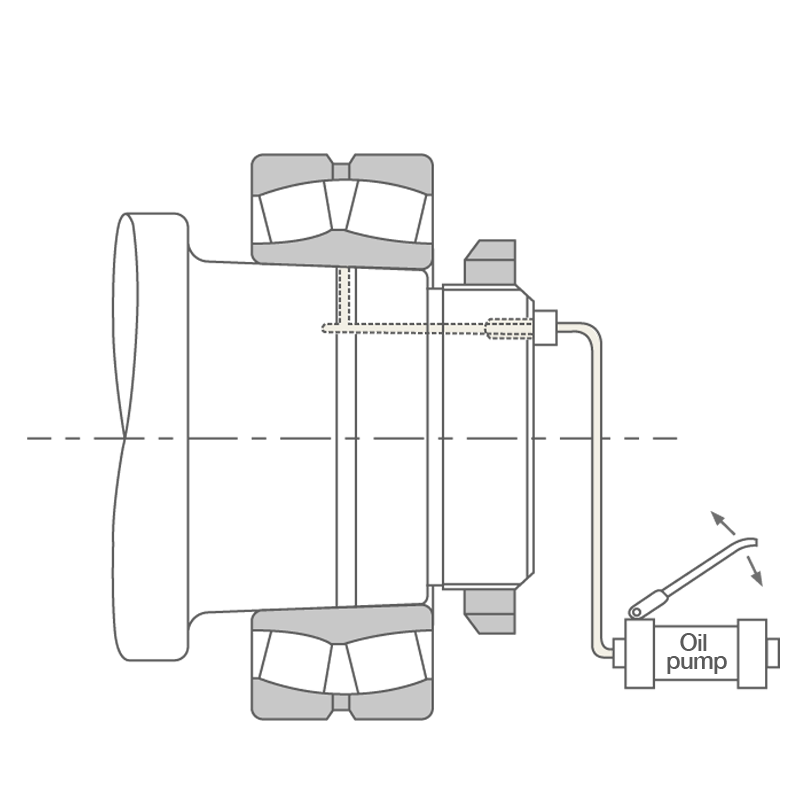

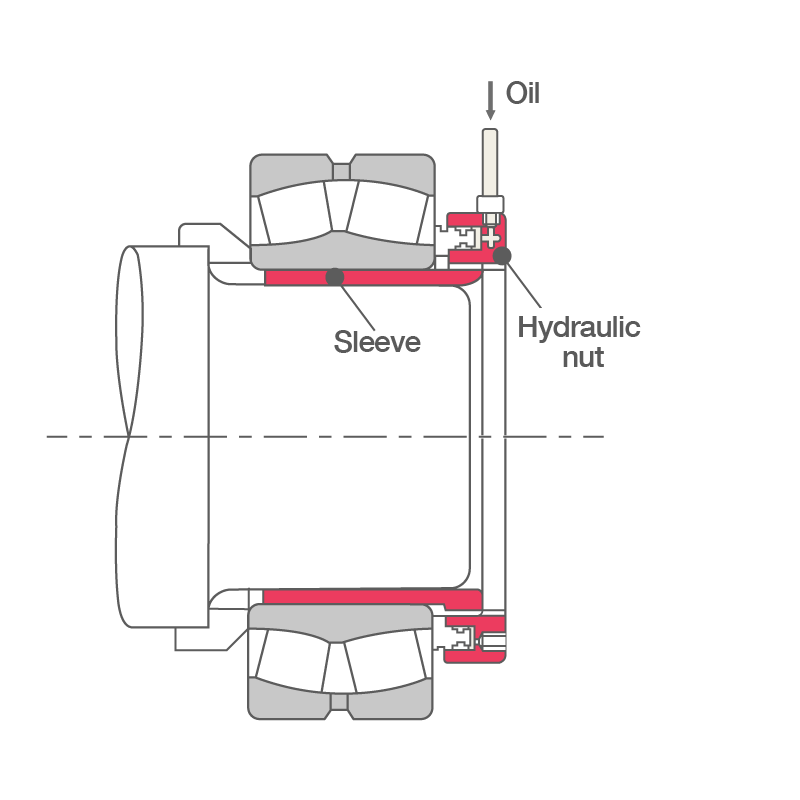

Dismounting Large Bearings With Tapered Bores

In large bearings, pressurized oil is can be supplied through holes in the tapered shaft, as shown in the left of the figure below. This expands the inner ring, allowing for easier dismounting.

A hydraulic nut may also be used to remove a bearing mounted on a sleeve, as shown on the right. A stopper is recommended to prevent the bearing from suddenly coming off the shaft.

Hydraulic oil

Hydraulic nut