11—Damage and Countermeasures

If a bearing is damaged, it is important to identify the cause to prevent recurrence.

Understanding changes in sound, vibration, and temperature prior to damage can help to determine effective countermeasures and extend life.

Bearing Damage

If handled correctly, bearings can typically be used until their predicted fatigue life. However, premature damage will render a bearing inoperable sooner than expected. Such damage is often due to improper handling, improper mounting, poor assembly, incorrect or insufficient lubrication, or inadequate consideration of the operating environment or temperatures during the design stage.

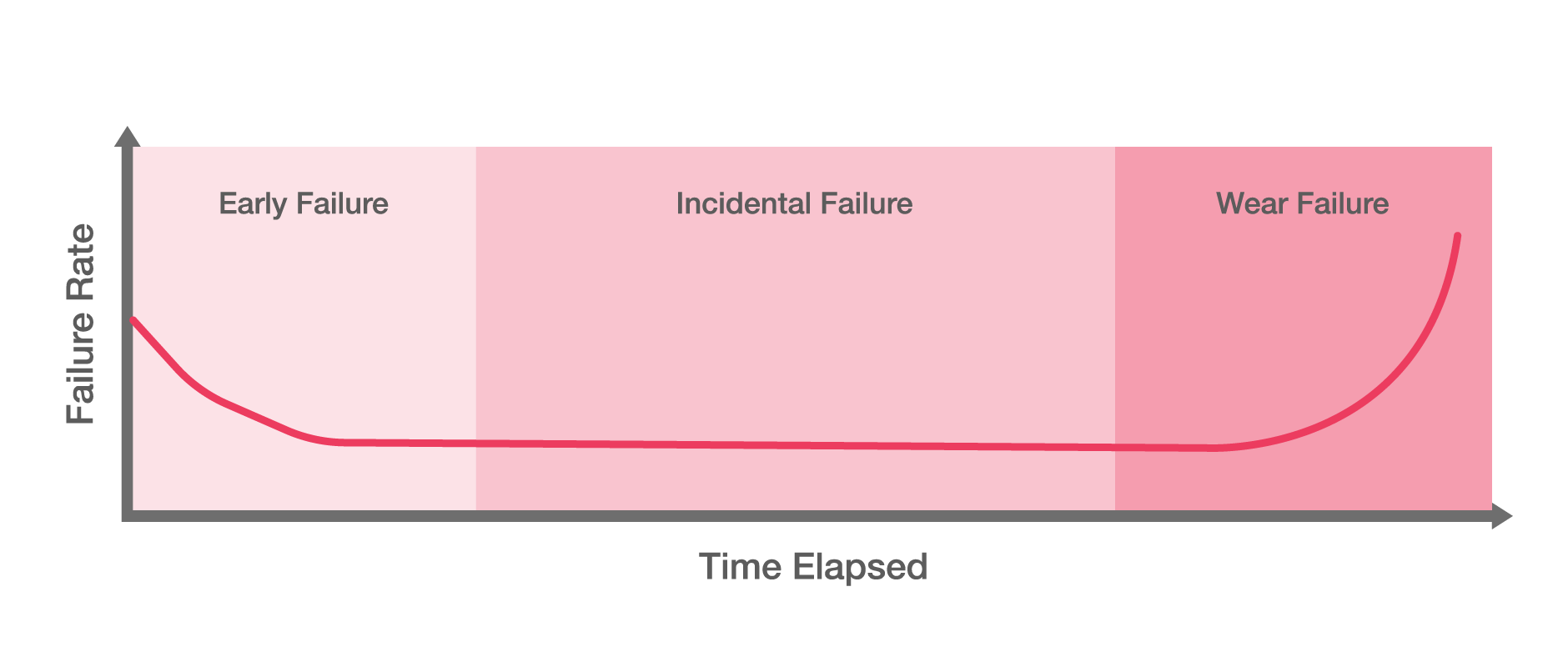

| Premature Failure | Incidental Failure | Wear Failure | |

|---|---|---|---|

| Characteristics | Failure after only a short period of operation | Failure after a period of stable operation | Increased failures due to end of component life |

| Major Causes | Material defects, assembly defects, design flaws, operating errors | Poor maintenance, changes in use environment | Normal life (wear/fatigue, aging) |

| Countermeasures | Sufficient running-in, checking for abnormal noise, vibration, and temperature | Maintain maintenance quality or improve maintenance in response to changes, replace lubricants, and ensure proper operation | Preventive maintenance (replacement based on advance predictions) |

Bathtub curve (failure rate)

Damage Causes by Timing

The primary cause of damage can be inferred based on its timing. Possible causes for damage are listed in the table below.

Timing | Probable Main Cause | |||||

Improper selection | Design or manufacturing error in shaft, housing, or surrounding parts | Improper lubrication method, type, or amount | Bearing flaws | Improper mounting | Entry of contaminants, moisture, or lubricant loss from faulty seals, wear, etc. | |

Shortly after mounting | ● | ● | ● | ● | ● |

|

After periodic inspection (disassembly) |

|

| ● |

| ● |

|

After replenishing lubricant |

|

| ● |

|

|

|

After repair/ replacement of shaft, housing, or surrounding parts |

| ● | ● |

| ● |

|

During normal operation |

|

| ● |

| ● | ● |

Damage Causes by Operating Characteristics

Certain operating characteristics can suggest specific issues:

| Characteristic | Cause | ||

|---|---|---|---|

| Noise | Low metallic noise |

| |

| High-pitched metallic noise |

|

| |

| Irregular noise |

|

| |

| Gradually changing noise |

|

| |

| Abnormal temperature |

|

| |

| Loss of running accuracy |

| ||

| Rough operation |

|

| |

| Contamination of lubricant |

|

| |

Running Traces and Applied Loads (Deep Groove Ball Bearings)

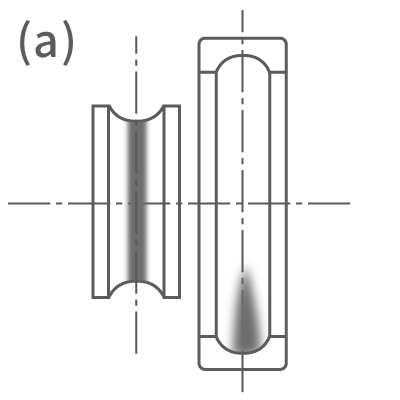

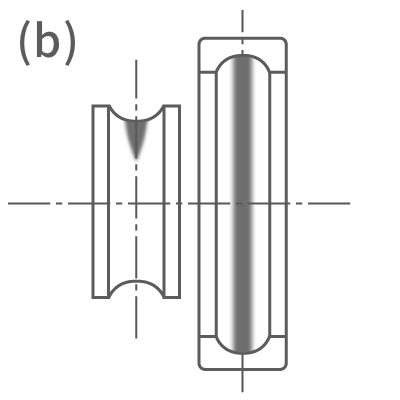

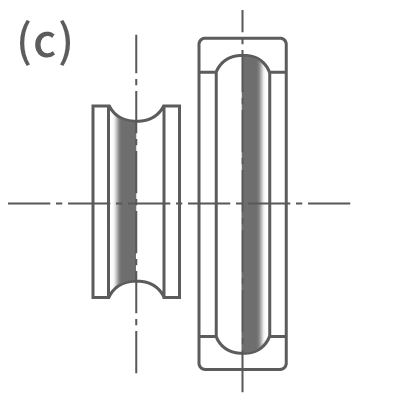

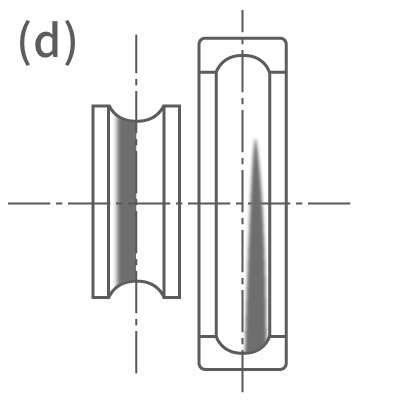

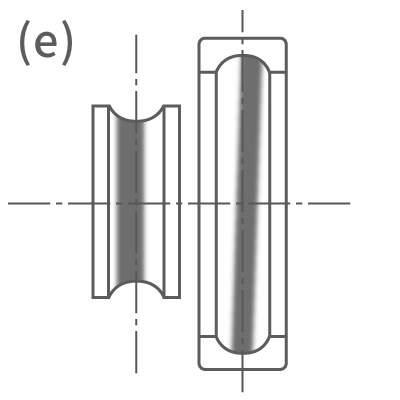

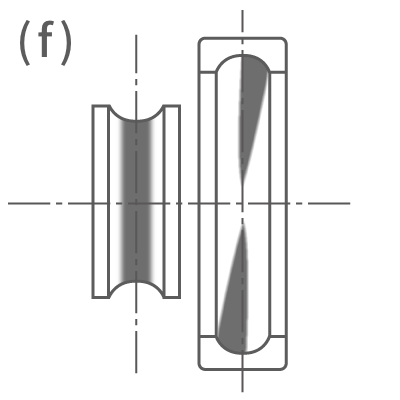

As a bearing rotates, dull areas develop on the raceway surface from rolling contact with the rolling elements. This coloration is called a “running trace” and is a normal phenomenon. Figures (a) through (d) below show normal running traces. However, the running traces in (e) through (h) suggest conditions that may negatively affect the bearing and lead to a shortened life.

Normal running traces

Inner ring rotation

Radial load

Outer ring rotation

Radial load

Inner or outer ring rotation

Axial load in one direction

Inner ring rotation

Radial and axial loads

Abnormal running traces (conditions may shorten life)

Inner ring rotation

Axial load and misalignment

Inner ring rotation

Moment load

(misalignment)

Inner ring rotation

Oval housing bore

Inner ring rotation

No internal clearance

(Negative operating clearance)

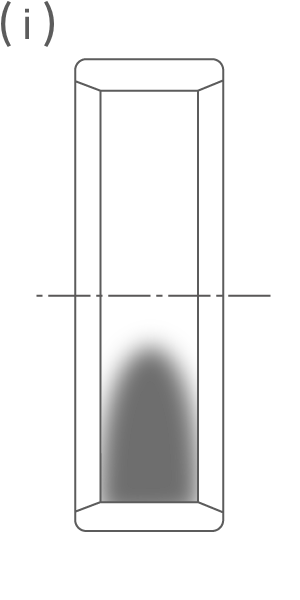

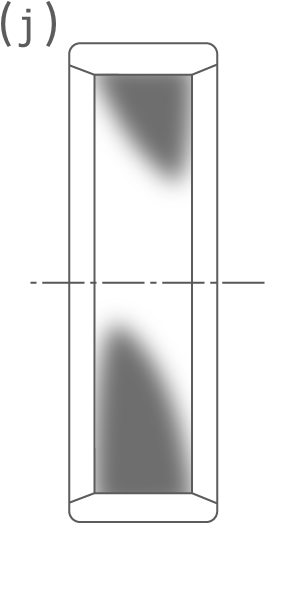

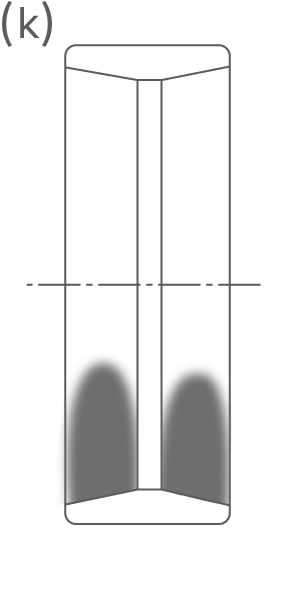

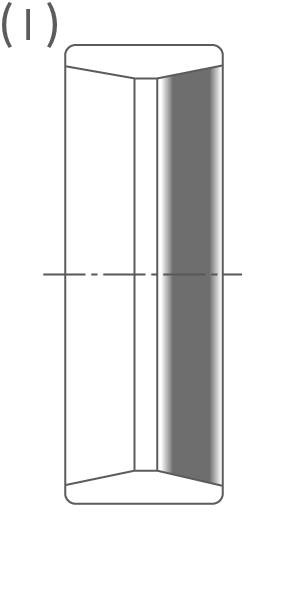

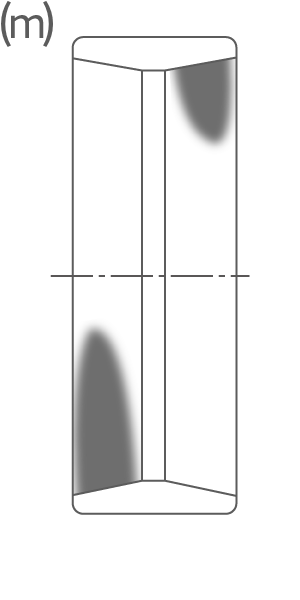

Running Traces and Applied Loads (Roller Bearings)

Dull areas also develop on the outer ring raceway surface of roller bearings from rolling contact with the rollers. Running traces are not an anomaly; rather, they provide excellent information on load conditions.

Inner ring rotation

Radial load

Inner ring rotation

Moment load (Misalignment)

Inner ring rotation

Radial load

Inner ring rotation

Axial load

Inner ring rotation

Radial and moment loads (Misalignment)

(i), (j): Outer rings of N-type single-row cylindrical roller bearings

(k), (l), (m): Outer rings of KBE-type double-row tapered roller bearings

Damage and Countermeasures

| Flaking (Spalling) | |

|---|---|

| Condition | As a bearing rotates under load, pieces of the raceways of the inner/outer rings and the rolling surfaces of the rolling elements peel off in an scaly pattern due to rolling fatigue. |

| Cause |

|

| Countermeasures |

|

| Example |

|

Photo

| Fretting | |

|---|---|

| Condition | Fretting is a type of wear caused by repeated and relative micro-slips between two surfaces. It occurs at the contact area between the ring and rolling elements and at fitting surfaces. It is sometimes called fretting corrosion due to the reddish brown or black wear particles produced. |

| Cause |

|

| Countermeasures |

|

| Example |

|

Photo

| Dents | |

|---|---|

| Condition | Fine particles or foreign matter trapped in the bearing create indentations on the raceway/rolling contact surfaces. Impacts or shocks during mounting may also cause dents at the rolling element pitch interval. |

| Cause |

|

| Countermeasures |

|

| Example |

|

Photo

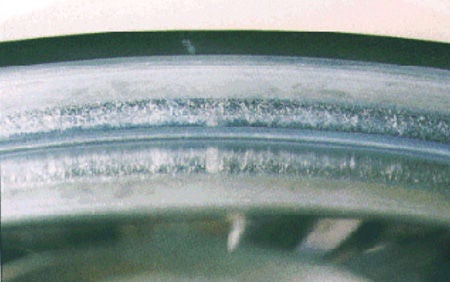

| Electrical Erosion | |

|---|---|

| Condition | Electrical erosion (sometimes called electric corrosion) occurs when an electric current flows through the oil film in the contact area between the raceways and rolling elements, causing sparking/arcing that melts the surfaces locally and makes them uneven. Visible dull areas are made up of small depressions called craters or pits. These may develop into an uneven axial pattern of ridge-like marks (fluting) with circumferential grooving. |

| Cause |

|

| Countrermeasures |

|

| Example |

|

Photo

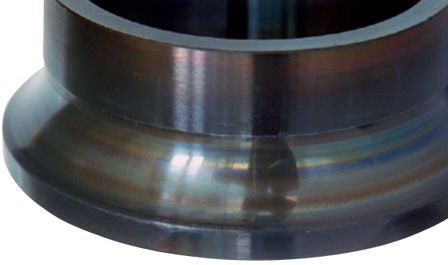

| Seizure | |

|---|---|

| Condition | During rotation, the rings, rolling elements, and cage heat up rapidly. If heat becomes excessive, parts may become discolored before softening, deforming, and melting, causing eventual seizing. |

| Cause |

|

| Countermeasures |

|

| Example |

|

Photo

| Discoloration | |

|---|---|

| Condition | Temperature rise and lubricant reactions/deterioration can cause changes in the color of the rings, rolling elements, and cage. |

| Cause |

|

| Countermeasures |

|

| Example |

|

Photo

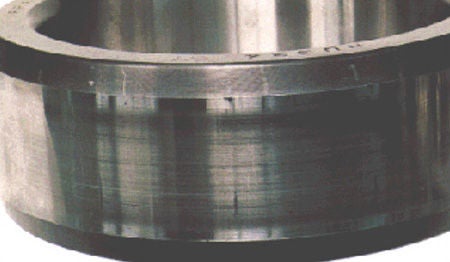

| Scoring | |

|---|---|

| Condition | Scoring is a kind of surface damage caused by localized bonding (adhesive wear) between sliding surfaces. On the raceway and rolling surfaces, linear damage occurs circumferentially. Cycloidal-shaped damage also appears on roller end faces and ribs in contact with the end face. |

| Cause |

|

| Countermeasures |

|

| Example |

|

Photo

| Mounting Flaws | |

|---|---|

| Condition | Linear scratches in the axial direction on raceways and rolling surfaces caused by improper mounting, dismounting, or handling. |

| Cause |

|

| Countermeasures |

|

| Example |

|

Photo