Bearing Basics (Uses, Types, and Components)

Let's first take a look at how bearings are used and the many types of bearings available. We'll also identify the main components found in rolling bearings and explore how they differ from plain bearings.

What Are Bearings and How Are They Used?

- Bearing benefits

Bearings increase the efficiency of movement in machines by reducing friction.

With less friction, equipment lasts longer.

In this way, bearings are crucial machine components that keep equipment moving. - Bearing types

Plain bearings (or sliding bearings) use a liquid, solid, or gas to create sliding friction between the shaft and bearing whereas rolling bearings (or rolling-element bearings) move with efficient rolling friction through the use of balls or rollers.

Plain (sliding) bearing

Rolling bearing

Types of Sliding Bearings

・Liquid-lubricated bearings: White metal, copper, lead alloys, etc. ・Oil-lubricated bearings (rolling bearings also utilize these lubrication methods):

・Water-lubricated bearings: Using water promises to be more environmentally friendly than oil. |

| ・Gas bearings: High rotational accuracy and low friction bearings for applications unsupported by rolling bearings. |

| ・Magnetic bearings: Magnetic forces support the shaft. |

| ・Hydrostatic bearings: The shaft floats on a cushion of pressurized gas provided by a pump, etc. (used in ultra-precision machining tools/measuring instruments, etc.) ・Hydrodynamic bearings: The shaft is supported by an oil film created by the rotation of the lubricated shaft (typically grooved, used in video/information equipment, etc.) |

Advantages of Rolling Bearings (vs. Plain Bearings)

Rolling bearings have six advantages over plain bearings:

1. In general, rolling bearings offer lower friction with high rigidity.

2. Dimensions, accuracy, markings, and so on are standardized internationally (ISO, ANSI/ABMA, JIS, etc.), making rolling bearings readily available and interchangeable.

3. Rolling bearings are easy to maintain, replace, and inspect.

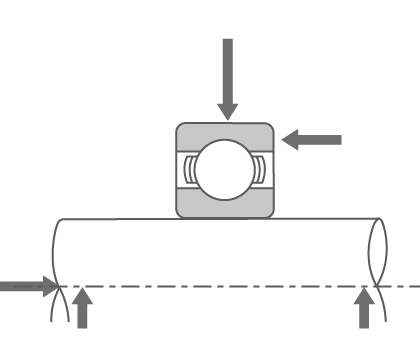

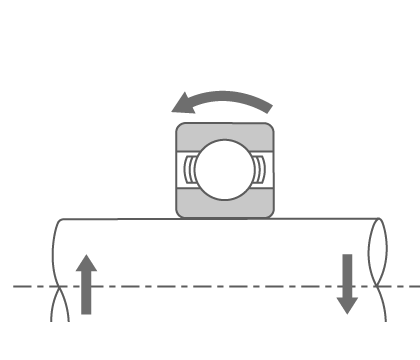

4. Depending on the type, rolling bearings can take radial, axial (thrust), moment, or combined loads.

5. Rolling bearings can be used over a wide temperature range.

6. Certain types of rolling bearings, such as angular contact ball bearings and tapered roller bearings, can be preloaded for high rigidity.

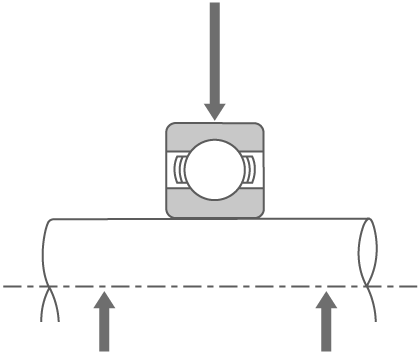

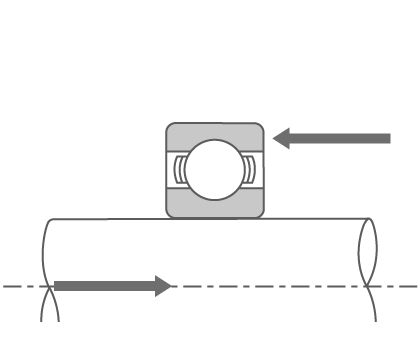

Radial load

Axial load

(Thrust load)

Combined load

(Both radial and axial load)

Moment load

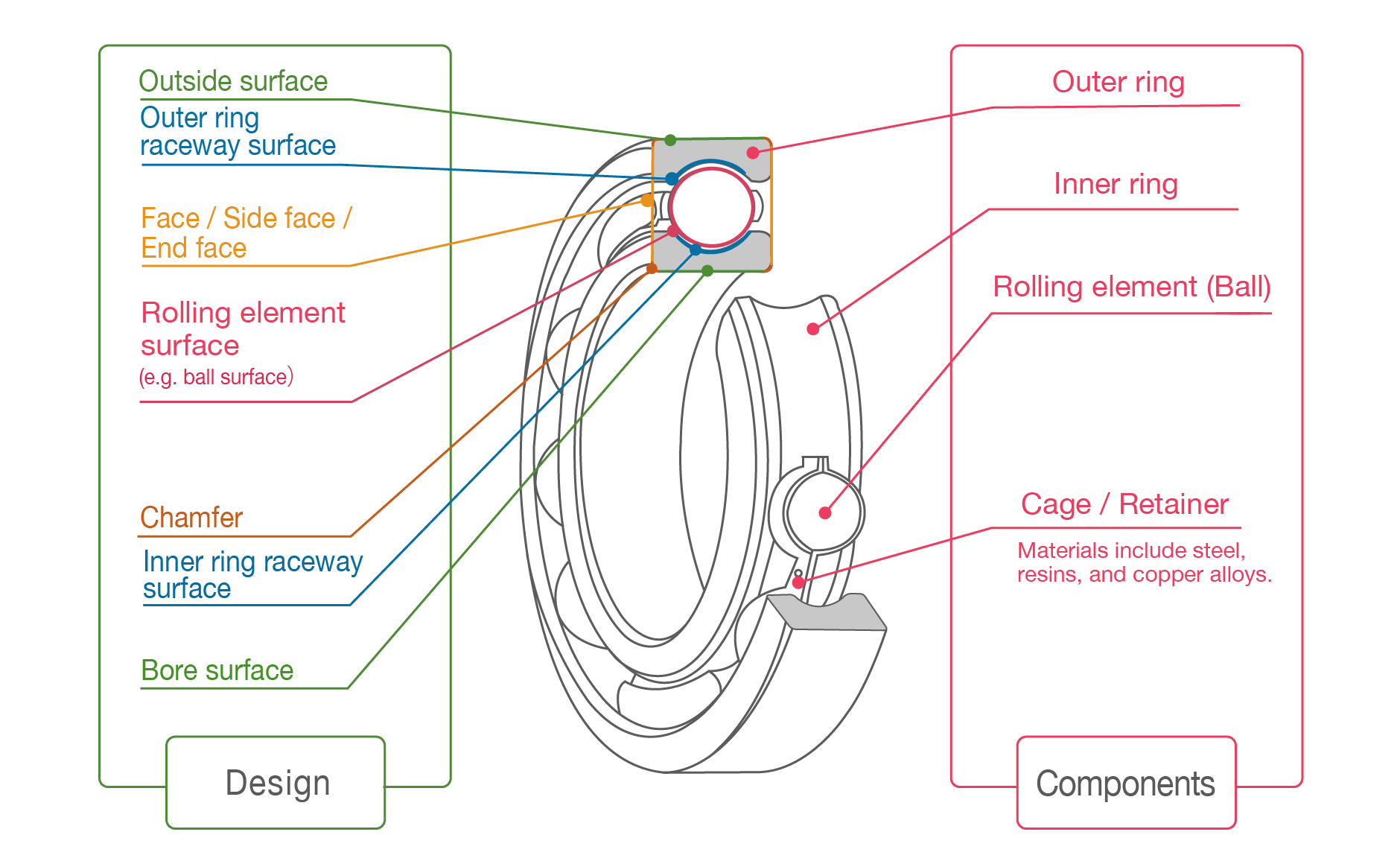

Structure and Main Components

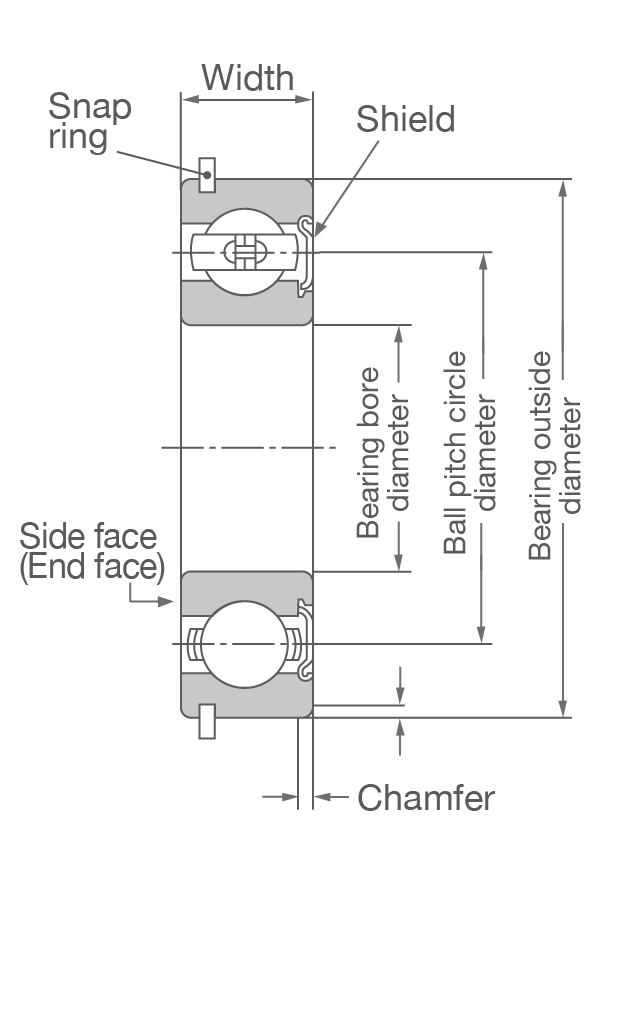

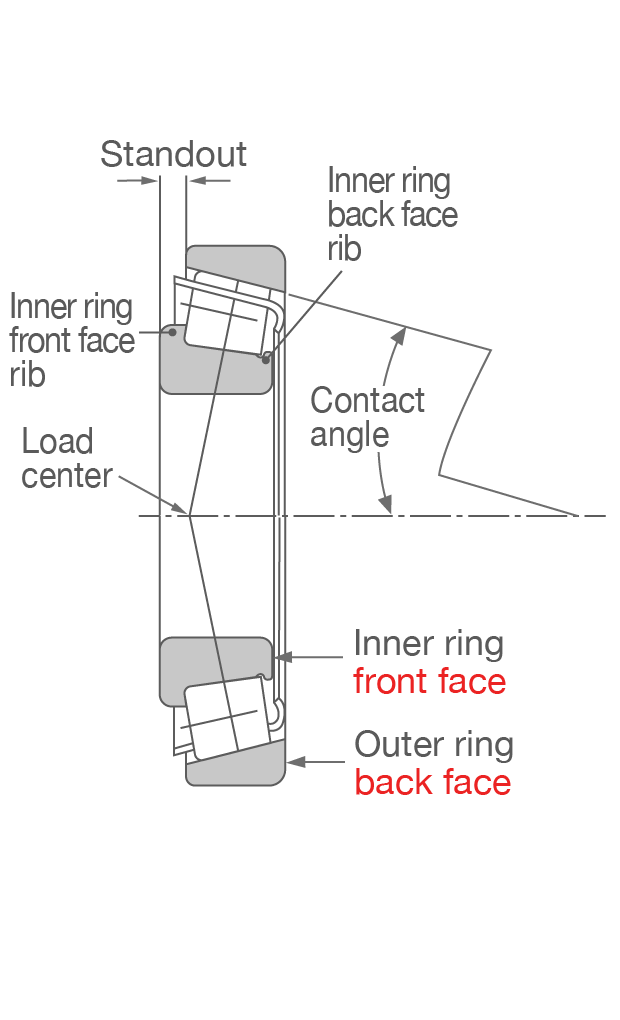

Rolling bearings (hereinafter, “bearings”) generally consist of raceway rings, rolling elements, and cages. A typical bearing appears as shown here:

Structure and Main Components

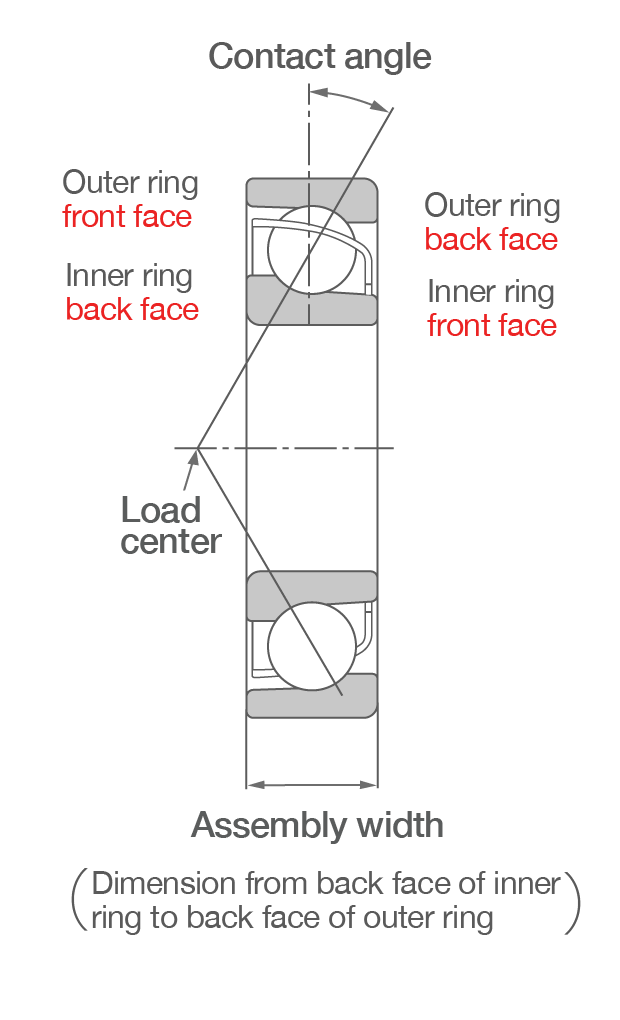

Single-Row Angular Contact Ball Bearing

Single-Row Deep Groove Bearing

Tapered Roller Bearing

Cage Role and Types

Role of the cage

Many bearings feature cages. A cage maintains proper spacing between rolling elements and helps the rolling elements move smoothly, supporting bearing rotation.

- Cages prevent the rolling elements (balls or rollers) from slipping or separating from the outer or inner ring.

- Cages keep the rolling elements evenly spaced.

- This prevents contact between rolling elements, suppressing additional friction and helping maintain smooth rotation.

Without a cage:

With a cage:

Cage Types

There are three broad categories of cages based on their materials.

Cages are typically determined by usage conditions, but options may be limited for some bearing types and sizes.

| High Speeds | Rigidity | High Temperatures | Low Noise | Lubricant Compatibility | Cost | |

|---|---|---|---|---|---|---|

| Pressed-steel cage (Pressed cage) | 〇 | 〇 | 〇 | |||

| Machined-brass cage | 〇 | 〇 | 〇 | 〇 | ||

| Synthetic-resin cage (Injection-molded, Plastic) | 〇 | Varies by material | 〇 | Varies by material | 〇 |