NSK Bearings Making a Difference in Trains: Safer, More Comfortable, and Lower Environmental Impact

Among the various means of transportation such as cars, trains, planes, and boats; trains emit the least amount of CO2 per kilometer. We interviewed engineers who are involved in the design, development, and evaluation of bearings for trains to achieve high safety, comfort, and environmental performance.

Profile

Yasuhiro Tomida (left)

Coordinator

Railroad & Aerospace Bearing Technology Department

Industrial Machinery Bearing Technology Center

Industrial Machinery Technology Center

Haruki Taguchi (center)

Railroad & Aerospace Bearing Technology Department

Industrial Machinery Bearing Technology Center

Industrial Machinery Technology Center

Yoji Horii (right)

Coordinator

Railroad & Aerospace Bearing Technology Department

Industrial Machinery Bearing Technology Center

Industrial Machinery Technology Center

Bearings contribute to many functions of rolling stock (railcars)

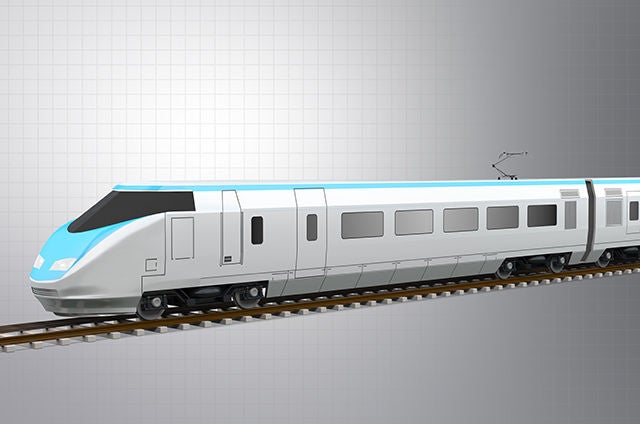

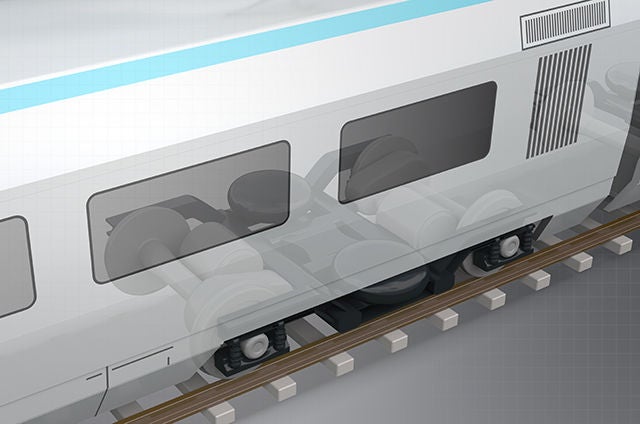

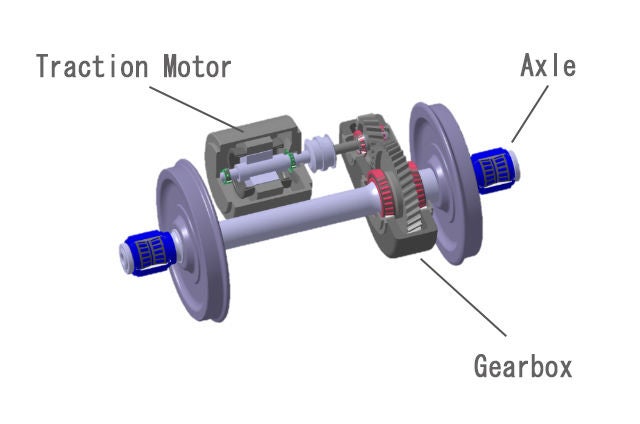

Horii A typical railcar consists of a body that carries people or goods, and two bogies that support the car body and enables it to run on the track. The bogie contains the axles that support the car body, the traction motors that drive the wheels attached to the axle, and the gearbox. Our bearings are used in all of these parts: the axle, traction motor, and the gearbox.

Bogie (wheelset, axle, motor, etc.) at the bottom of the railcar

Each application employs different bearings

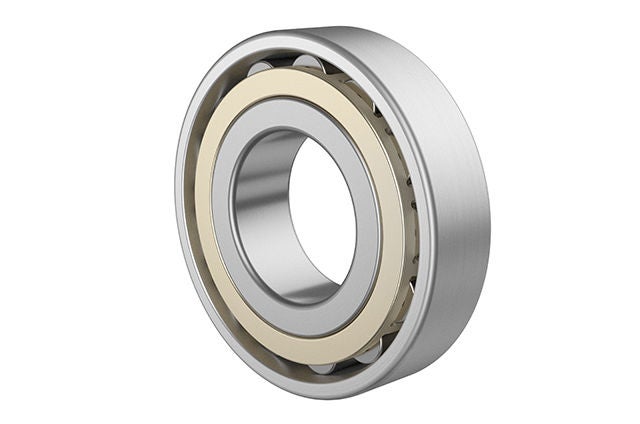

Tomida Bearings are designed and developed to meet the different requirements of different applications, such as high-speed rotation, low noise, and prevention of electrical corrosion caused by the passage of electric current through the bearing.

NSK’s technological strength has continued to grow along with the evolution railcars

Horii Trains excel in safety and punctuality, and regular maintenance is indispensable to achieving these goals. Since the operating environment differs from country to country and region to region, bearings must be durable enough to last over the maintenance period required by each country. In recent years, the number of skilled railcar maintenance workers has been decreasing due to declining workforces, and the need for bearings that are easy to maintain has been increasing as a trend in the sector.

Tomida Since 1932, when NSK developed tapered roller bearings for the axles of gasoline-powered trains run by Japan’s national railroads, the company has grown together with customers especially through the development of the Shinkansen bullet trains. NSK bearings have been used in all types of Shinkansen models since the first Shinkansen, the 0 Series, began operation in 1964. NSK bearings are also used in the Tokaido and Sanyo N700S Shinkansen, which is the newest model that began commercial operation in July, 2020. Our newest Shinkansen bearings are lighter and feature higher lubrication performance, improvements that we achieved through a rigorous iterative design and development process.

Flanged cylindrical roller bearings used in the gearbox of the N700S

Taguchi Thanks to NSK’s proven track record and technological capabilities in Japan, NSK has made significant inroads into the global rolling stock market since the 2000s. Today, NSK provides bearings for many rolling stock manufacturers around the world, including those in China, Korea, Europe, and other countries. This was realized by promoting design, development, and evaluation that takes into account the driving environment of each country by utilizing our accumulated technological capabilities and knowledge.

With a sense of responsibility

Horii Whenever a new employee joins our department, the first thing I tell them is that our products can influence people’s lives. Also, when designing, I tell the members around me to not only look at the surface, but to also look at the underlying reasons.

I believe that the number of our global customers will continue to increase more and more in the future, and I would like to deepen cooperation with our technical centers outside Japan to understand the differences in the market and evolve our technology.

Tomida I believe that our mission is to responsibly deliver high quality and highly reliable products to the world. For this reason, when I have a question or concern during my development work, I do not leave it ambiguous, but thoroughly seek out the answer. It feels great to ride on a train equipped with a product I designed, and this motivates me. I will continue to work closely with railway operators to improve the comfort and convenience of passengers. I hope that we can realize a future where highly safe and reliable trains made with NSK products are used in every country.

Taguchi I am happy to be involved in the railroad industry, which is closely related to people’s daily lives. Railroads are vehicles in which even a single broken component could lead to a critical accident involving many human lives. When conducting evaluation tests, I always maintain a sense of responsibility, faithfully accepting the data obtained and ensuring that I do not overlook even the smallest of changes and that I give them careful consideration.

I believe that NSK’s technology, which has been supporting the safety of Japan’s rolling stock, can contribute to the realization of a safer and more comfortable life on a global scale as well. In addition, railcars are eco-friendly vehicles with low CO2 emissions. I would like to think about what NSK can do to further contribute to the environment around the world, and endeavor to discuss this with rail industry persons at every opportunity.