NSK, Ltd.

Corporate Communications Department

NSK Welcomes Visitors to the Japan Mobility Show 2025

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) will exhibit at the Japan Mobility Show 2025, which is hosted by the Japan Automobile Manufacturers Association, Inc., and will be held at Tokyo Big Sight from October 30 to November 9, 2025.

■ Event Outline

In addition to domestic and international automobile and parts manufacturers, this event will feature exhibits from mobility-related companies beyond the scope of the automotive industry. Various programs and interactive events designed to meet diverse needs are also planned.

In 2023, at the previous event, approximately 500 companies participated and about 1.11 million people attended.

■NSK Booth Concept: “Mobilizing Tomorrow Today”

NSK will exhibit a wide range of products that address comfort in addition to the fundamental functions of cars like driving, steering, and braking. NSK will also exhibit products that are helping to build a mobility society.

NSK will also offer an interactive corner where visitors can learn about the mechanisms of products in a fun way, for instance by enjoying a bearing assembly experience.

■Main Exhibits

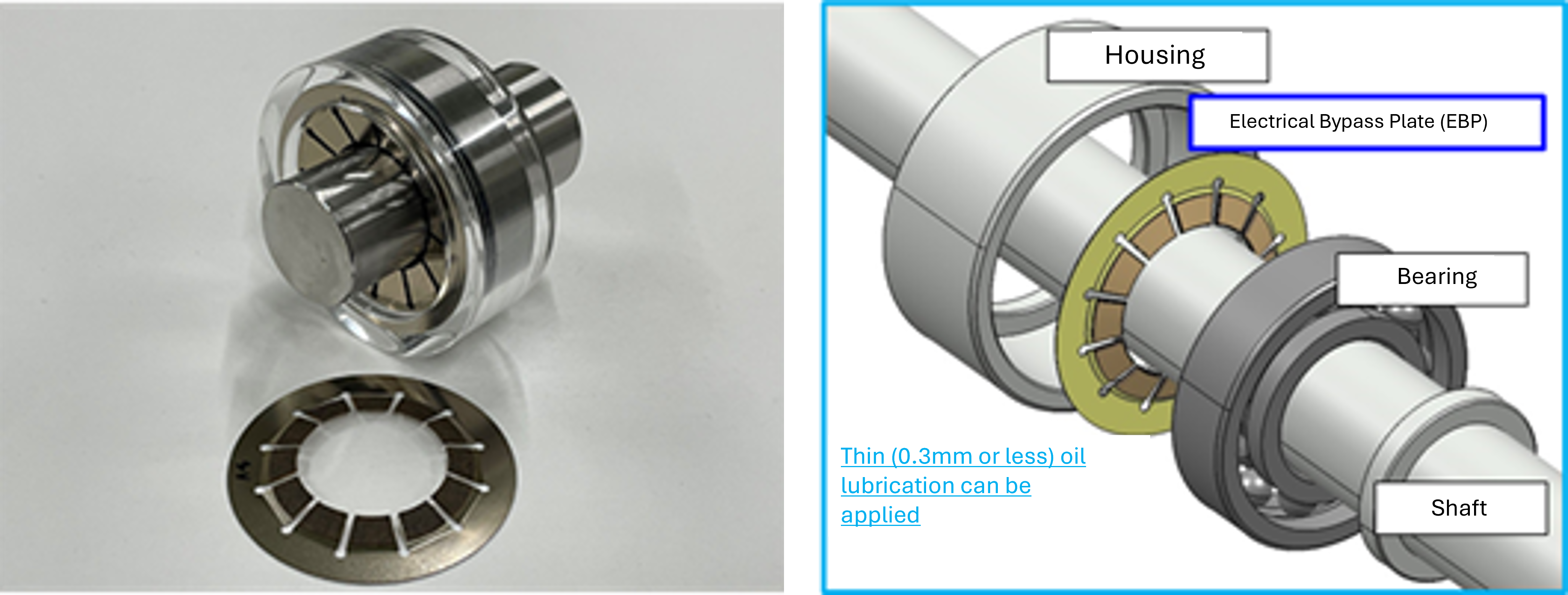

1) Driving: Electrical Erosion Resistant and EMC Countermeasure Conductive Item – Electrical Bypass Plate (EBP) (developed by NSK-Warner K.K.)

New Product and World-First Exhibit

As motors increase in capacity, there is a demand for countermeasures against bearing electrical erosion1 and electromagnetic compatibility (EMC) to address sources of electromagnetic noise.

*1 Electrical erosion is a problem where a discharge occurs inside the bearing due to a potential difference around the bearing, causing striped damage known as ridge marks to appear on the raceway surface, originating from slight irregularities.

Conductive items for electrical erosion and EMC countermeasures require space savings, conductivity, and durability. This product achieves a conductive structure that bypasses the bearing with an additional axial space of 0.3 mm or less, by utilizing a product structure that leverages spring reaction force and an independently developed conductive paper.

This product is sized to be mounted on a motor shaft, demonstrates high conductivity and durability under oil lubrication to act as a countermeasure to electrical erosion and EMC. NSK is planning to bring this product to market in early 2026.

2) Driving: Compact, Lightweight Deep Groove Ball Bearing for Electric Vehicles

By adopting a newly developed narrow-width combined plastic cage and combining it with NSK’s existing technologies, this product delivers a compact, lightweight design, narrow width, low friction, and high speed while maintaining a high level of performance in strength and lifespan, compared to conventional products. The outer diameter is reduced by about 10%, the width by 38%, the weight by about 51%, and the torque by 25%. Installing this product helps achieve smaller and lighter electric vehicle drive units, as well as improved power efficiency through reduced bearing friction.

NSK plans to introduce this product for electric vehicles to the market in the near future, targeting 4 billion yen in annual global sales by 2030.

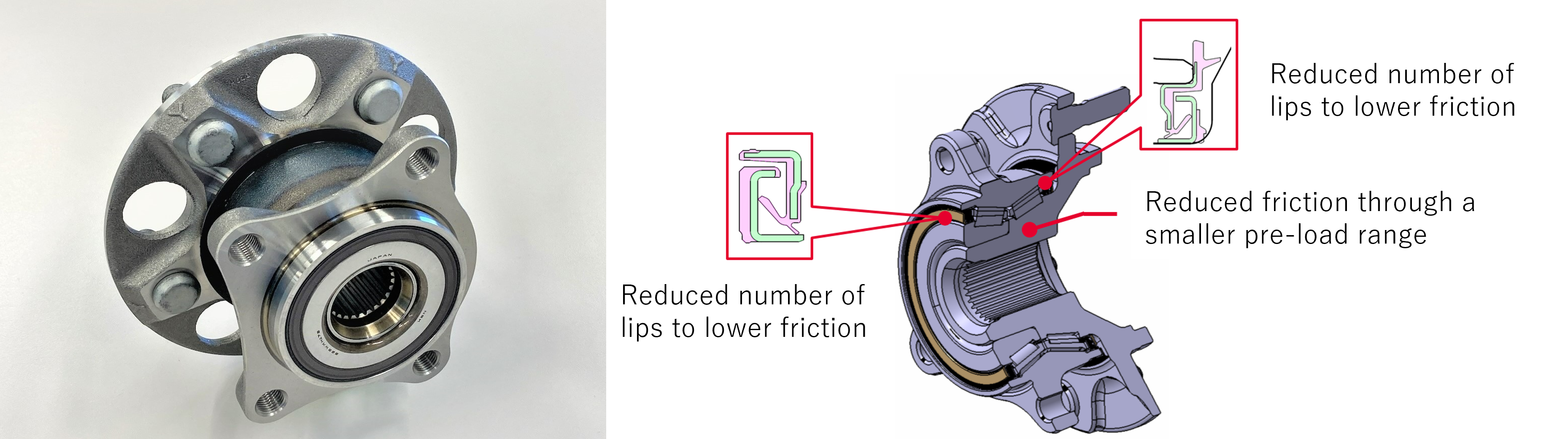

3) Driving: Ultra-Low Friction T-HUB (Tapered Roller) Unit Bearing

For heavy vehicle categories such as large SUVs and pickup trucks, tapered roller bearings are used because they have a greater load capacity than ball bearings. Since tapered roller bearings have higher friction than ball bearings, there is a demand for friction reduction. Furthermore, because these vehicles are often used in harsher environments than passenger cars, such as on rough terrain or for long distances, reliability in sealing and durability is also essential.

This product maintains high reliability even in harsh environments and achieves low friction by employing low-friction seals and low-friction grease.

4) Steering: Locking Clutch

This product balances high power transmission efficiency and a reliable locking function without using electricity, making for more efficient, smaller rear-wheel steering actuators. By installing this product in a rear-wheel steering actuator in combination with a ball screw, the efficiency of steering force transmission from the motor to the tires is improved, all while maintaining a self-locking function with zero electric power consumption. (See images below)

5) Braking : Ball Screws for Electric-Hydraulic Brake Systems

Due to the electrification of cars, autonomous driving, and the mandatory use of collision damage mitigation brakes, the adoption of electric brake systems is expanding. In particular, the adoption of ball screw-type electric brakes, which offer excellent responsiveness, is expected to grow. Additionally, using a low-friction ball screw in the actuator is expected to improve the performance of the brake system.

This product improves brake responsiveness with its high response capability and enhances brake control through stable efficiency. Furthermore, the overall system can be made smaller and lighter by integrating NSK bearings and surrounding parts.

NSK started production of this product at its Saitama Plant in March 2018 and at its Dongguan Plant in China in April 2021. The company aims to establish a global production system with an annual capacity of 10 million units by 2026.

6) Electric Corner Module Concept

The Electric Corner Module Concept is a conceptual model that integrates an electric suspension, rear-wheel steering actuator, electric mechanical brake, and ultra-low friction B-HUB unit bearing, among other components. (See images below)

Influenced by the electrification and smartification of automobiles, the chassis area is required to meet the need for efficient development while also enabling advanced autonomous driving and flexible component layouts. The Electric Corner Module Concept aims to facilitate the integration of hardware and software development by fully electrifying the actuators, providing a scalable smart platform, and promoting innovation in future mobility.

■Interactive Corner for Fun Learning

Visitors will be able to explore the mechanism of bearings in a bearing assembly experience. By picking up a bearing and having its attached tag read by a sensor, visitors can see the bearing’s function.

■Booth Details

Exhibition Name | Japan Mobility Show 2025 |

Venue | Tokyo Big Sight (Koto City, Tokyo) |

Dates | October 30 to November 9, 2025 |

NSK Booth | W3503 (West Hall 3/4) |

Official Website |

■About NSK

NSK produced the first bearings in Japan in 1916 and over the past 100 years, it has supported the development of industries worldwide by creating various innovative products and technologies in bearings, automotive parts, and precision machinery. Since the early 1960s, the company has expanded overseas and now has operations in about 30 countries. It ranks third in the world in the field of bearings and leads the world in ball screws, electric power steering, and other products.