NSK Ltd.

Corporate Communications Department

NSK Develops High-Efficiency Locking Clutch Mechanism “Locking Clutch” That Does Not Require Electric Power

Helping to Miniaturize Electric Actuators and Reduce Power Consumption in the Automotive and Industrial Machinery Industries and Beyond

● Delivers highly efficient power transmission and reliable locking performance without the need for electric power, leveraging the friction control technology developed over many years by NSK.

● Applying this technology to the rear wheel steering actuators on vehicles, power transmission efficiency from the motor to the wheels can be improved by roughly 70% over conventional mechanisms, without sacrificing the self-locking function that prevents external forces from being transmitted to the motor.

This allows actuator motor size to be reduced by approximately 40% over conventional mechanisms, thereby helping to reduce power consumption.

● In addition to automotive applications (vehicle height adjustment, power doors, seats, etc.), it can also be employed in a wide range of applications from parking mechanisms in automated guided vehicles (AGV) and transfer robots, to lifting apparatus, and other types of industrial machinery.

NSK Ltd. has developed the “Locking Clutch” that helps to miniaturize electric actuators and reduce power consumption actuators in the automotive and industrial machinery industries and beyond.

NSK Ltd. plans to exhibit this product at the Automotive Engineering Exposition 2024 Yokohama to be held May 22–24, 2024. Thereafter, the company will invite customers to evaluate samples before introducing the product to the market. NSK expects to achieve sales for this product of 3 billion yen by 2030.

Newly developed product (“Locking Clutch”)

1.Background

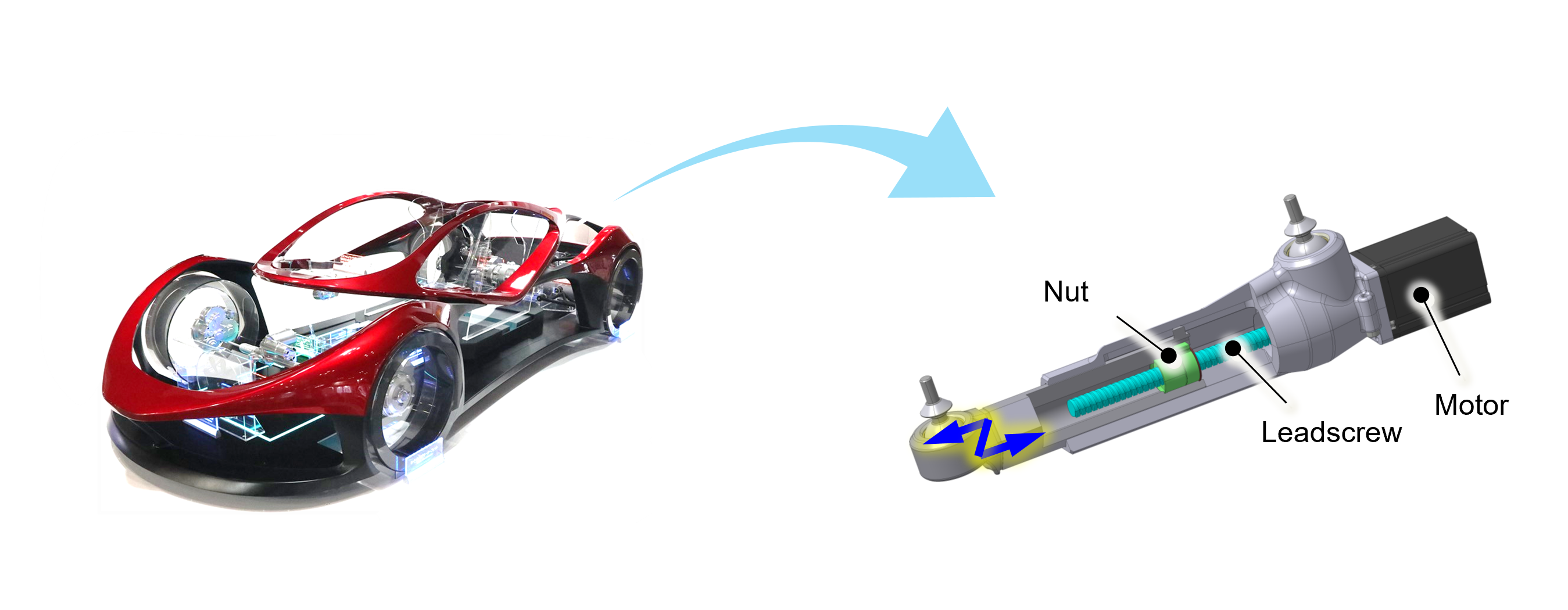

1) Demand for Rear Wheel Steering Actuators

Demand for rear wheel steering actuators that can automatically control the movement of the rear wheels with high precision is growing due to the proliferation of electric vehicles and autonomous driving. Rear wheel steering actuators can effectively increase vehicle safety and comfort. Also, by reducing vehicle turning radius, they enable the wheelbase to be lengthened and larger batteries to fit in the extra space, thereby helping to increase vehicle driving range.

Rear wheel steering actuator for high-precision control of rear wheel movement

2) Rear Wheel Steering Actuator Mechanism

In general, conventional rear wheel steering actuators employ leadscrews, whose characteristics achieve the following two functions.

(1) Drive function: Transmits power from the motor to the wheel (controls the movement of the wheel by converting the rotational movement of the motor into linear movement)

(2) Position hold function: A self-locking function which prevents outside forces from being transmitted to the motor (the leadscrew self-locks so that incidental forces input from the road surface are not transmitted to the motor)

Rear wheel steering actuator drive function (left) and position hold function (right)

3) Rear Wheel Steering Actuator Issues

Rear wheel steering actuators which utilize leadscrews face the issue of low transmission efficiency for the drive function which transmits power from the motor to the wheels. On the other hand, ball screws with high transmission efficiency can be used to eliminate this issue. However, due to their characteristic, ball screws cannot self-lock, which means that electric power must be consumed to implement the position hold function.

4) Solution to Rear Wheel Steering Actuator Issues

NSK has developed the “Locking Clutch” which can self-lock. Combining this with a ball screw possessing high transmission efficiency allows the new product to improve the issue of rear wheel steering actuator drive function transmission efficiency, while also maintaining the position hold function.

How the newly developed product resolves issues

2. Overview of Newly Developed Product

“Locking Clutch” is a new mechanism for power flow control clutches which transmits rotation from the input shaft and locks rotation from the output shaft.

Transmits rotation from input shaft (left), and locks rotation from output shaft (right)

Installation point for this product in rear wheel steering actuators

3. Features of Newly Developed Product

1) High transmission efficiency and position hold function

Achieves highly efficient transmission and excellent locking performance without electric power consumption, leveraging the friction control technology developed over many years by NSK.

2) Helps to miniaturize and reduce power consumption in rear wheel steering actuators

Installing this newly-developed product along with ball screws, the transmission efficiency of the rear wheel steering actuator can be increased (by roughly 70%) when driven, while also providing a self-locking function for holding position.

This helps to make the motor size smaller in the rear wheel steering actuator (by approximately 40% compared to conventional mechanisms) and also reduces power consumption.

3) Contributes to the Automotive and Industrial Machinery Industries and Beyond

NSK expects this product to find application not only in rear wheel steering actuators, but in numerous other applications, including:

•Automotive: Vehicle height adjustment, power doors, power seats, power switching clutches

•Industrial machinery: Parking mechanisms in automated guided vehicles (AGV) and transfer robots, lifting apparatus, robotic arms, and electric cylinders as an alternative to hydraulic or pneumatic equipment..

About NSK

NSK began its journey manufacturing the first bearings in Japan in 1916, and has since developed into a global organization researching, designing, and manufacturing Motion & Control™ solutions essential for mobility and industrial applications. NSK is the top supplier of bearings in Japan and is the third largest supplier in the world by market share.

Our responsive products and technologies enhance automotive performance and industrial productivity while reducing energy consumption to unprecedented low levels. In the early 1960s, we set our sights outside Japan and have established over 200 business locations in 31 countries alongside a vast network of joint ventures and partnerships in all corners of the world.