NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed the NSK ball screw S-HTF Series for high-load drive applications, which contributes to improved productivity in electric injection molding machines and servo press machines. With this product launching in January 2017, NSK is targeting 1 billion yen in global annual sales of the product in 2020.

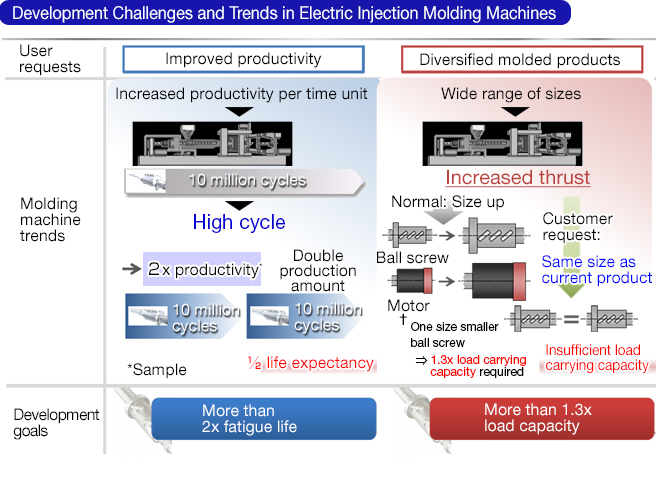

In recent years, the size and shape of plastic products have become diversified, from large parts for automobiles to everyday items and small electronics parts, and the demand is expected to continue growing. This will necessarily require increased productivity for electric injection molding machines and molded parts diversification.

High-cycle molding machines with accelerated feeding speed are required to improve productivity. To achieve this, ball screws with a long fatigue life are essential.

Meanwhile, the increased thrust and speed needed to cope with diversification of molded parts such as large molded products and complex shapes requires improved load carrying capacity from ball screws.

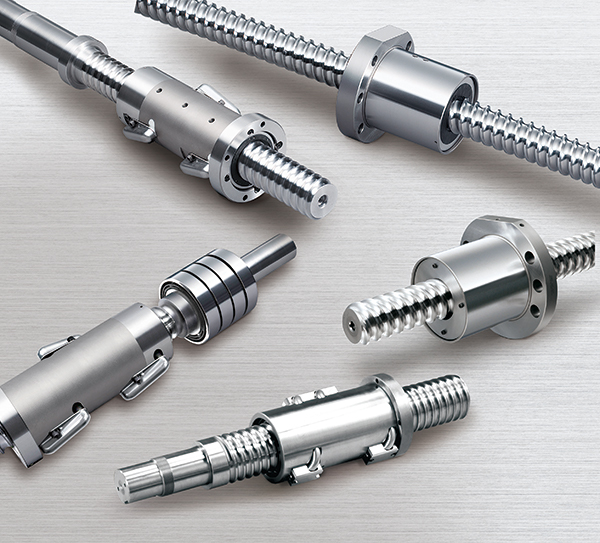

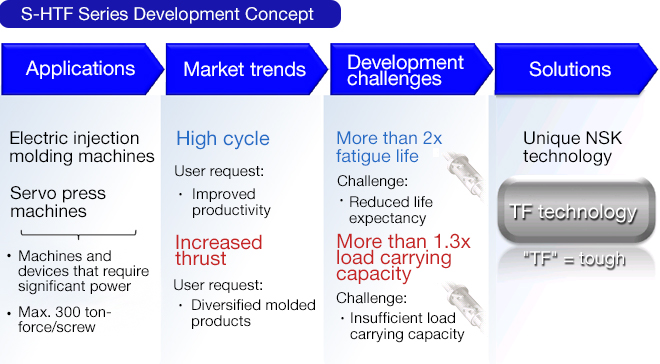

To meet the needs of electric injection molding machines and servo press machines, NSK has developed the S-HTF Series of ball screws for high-load drive applications.

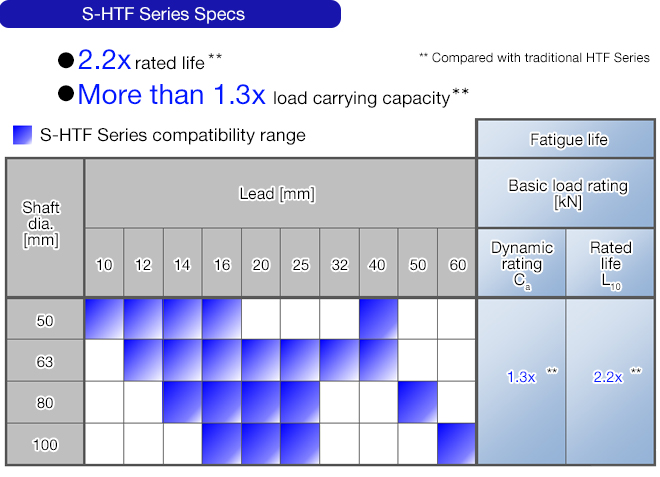

- Approximately 2.2 times longer fatigue life and up to 1.8 times greater load carrying capacity

- The new series features the world's first application of TF technology on a ball screw, which delivers longer fatigue life and improved load carrying capacity.

NSK ball screws for high-load drive applications are essential mechanical components in electric injection molding machines and servo press machines. In 1996, NSK developed the HTF series, the industry's first ball screws for high-load drive, then expanded the product lineup by responding to customer demands for faster, larger, products with reduced lubricants. NSK continues to provide “Your Real Partner.™” solutions by meeting market needs with versatility.