NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed the next generation of its Creep-Free™ lineup of bearings for hybrid and electric vehicles' drive components, such as transmissions. These new bearings help improve the comfort of hybrid and electric vehicles by suppressing the increase in vibration that is caused by the slip phenomenon in bearings known has creep. NSK is targeting 1.5 billion yen in global sales for this product in 2020.

In an effort to improve fuel economy, hybrid and electric vehicles typically employ compact, high-speed motors. However, when such motors spin at high speeds, a large imbalance load can occur, resulting in creep in the bearings which in turn can lead to wear in the bearings themselves. Once creep occurs in bearings, the transmission case on the outer side of the bearings will start to wear. The concern is that when this kind of wear occurs, it can lead to an increase in vibration coming from the transmission.

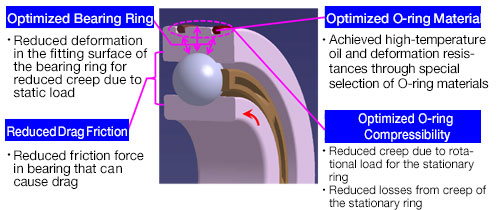

One form of creep encountered is static load*1creep, which occurs when the bearing ring is deformed due to the large amount of load exerted on the outer race of the bearing from the gears of the transmission. Another form of creep is rotational load*2 creep, which occurs due to gaps created between the case and outer race and imbalance loads that occur as the motors spin. In addition, drag can also occur in the outer race due to the frictional force that builds up in the bearing, potentially causing further creep in lightly loaded conditions.

NSK's Creep-Free™ bearings are anchored to the case by employing an O-ring on the outer surface of the outer race and, as such, are effective in preventing rotational load creep.

However, in using the approach of anchoring the bearing to the case, there were concerns in terms of cost and case assemblability. Another concern that arose was in ensuring enough oil resistance for the O-ring for high-temperature oil conditions.

In response to these concerns, NSK created the next generation of its Creep-Free™ bearings by optimizing the design and materials used so that the bearings would no longer need to be mechanically anchored. With the new design, creep occurrence is still suppressed, which reduces case wear and helps to lower the occurrence of vibration.

*1 Static load : Direction of load remains constant

*2 Rotational load : Direction of load continuously changes

These new bearings help improve the comfort of hybrid and electric vehicles without a large increase in cost.