NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed a highly dust resistant, low friction loss bearing for office equipment applications such as copy machines. This new bearing combines highly dust resistant performance with low friction loss capability.

NSK is targeting 1 billion yen in global annual sales for this product in 2020.

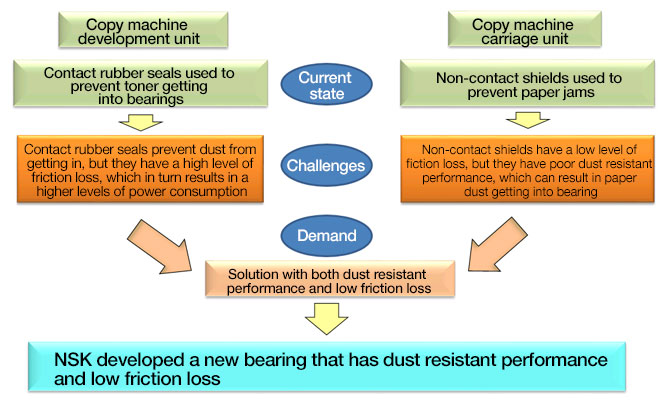

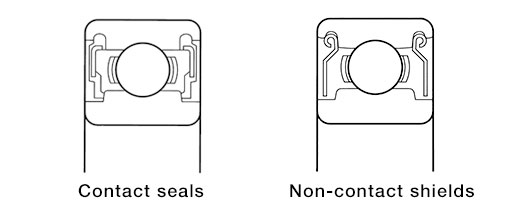

Bearings used in the development unit of copy machines are exposed to fine particulates such as toner. As a result, contact rubber seals with highly dust resistant performance are used to prevent the bearing from being contaminated by foreign matter. However, the challenge has been to find ways to reduce the friction loss of those contact seals in order to reduce power consumption.

In addition, the bearings used in the carriage of the copy machine can cause paper jams unless they rotate smoothly. For this reason, low friction loss, non-contact shields are used. However, especially in emerging countries where the paper quality is poor, paper dust is generated when the paper is conveyed by the rollers. Thus, another challenge has been the need to improve dust resistant performance to prevent the entry of paper dust into the bearing.

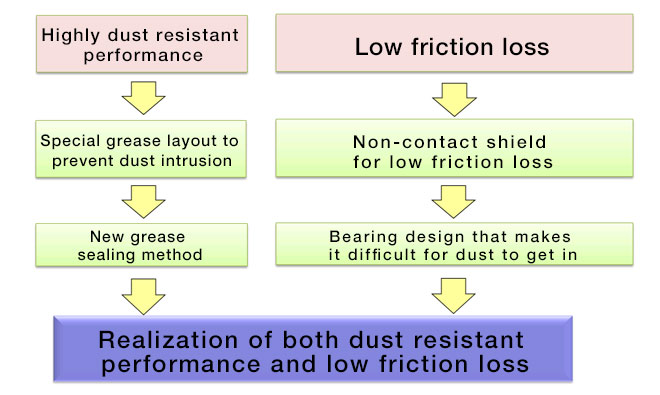

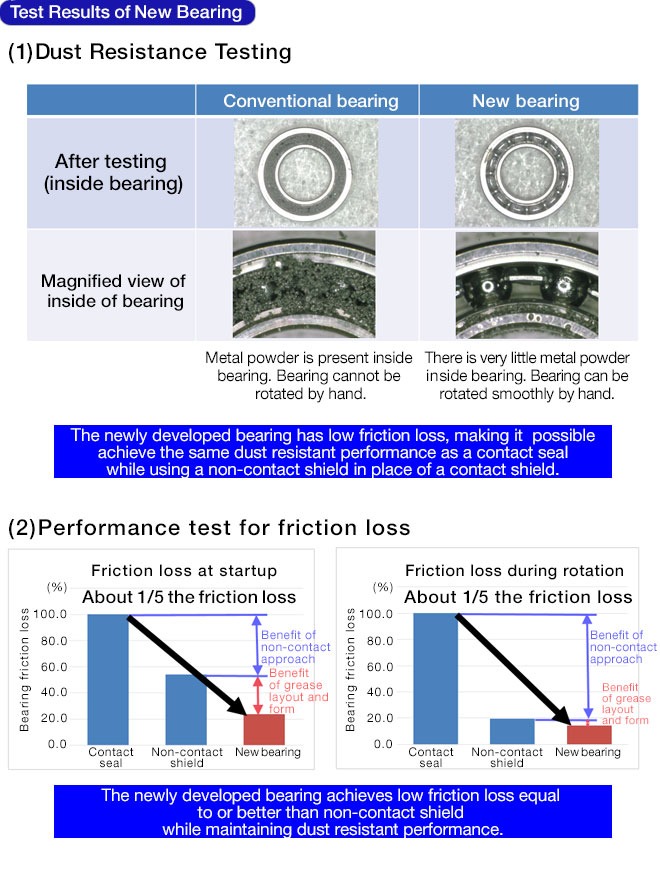

In response to these challenges, NSK has developed a bearing that has both highly dust resistant performance and low friction loss performance. The new product is suited for use in a wide range of applications, including both the carriage and development units of copy machines.