NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed an actuator that can elevate and rotate independently and determine its position in order to make it more compact and provide a versatile range of movement.

NSK will exhibit this new product at the International Robot Exhibition 2015 to be held at Tokyo Big Sight (Koto-ku, Tokyo) from Wednesday, December 2 to Saturday, December 5. In the future, NSK will search for potential practical applications for this product.

Production equipment is becoming ever smaller in order to accommodate the reduced size of electronic parts used in smartphones, tablets, and other devices that require more compact actuators for production.

Pneumatic and mechanical index table actuators are often used for the transport of small parts. The functions of pneumatic and mechanical index tables are limited, requiring a multi-function actuator to cope with production line diversification.

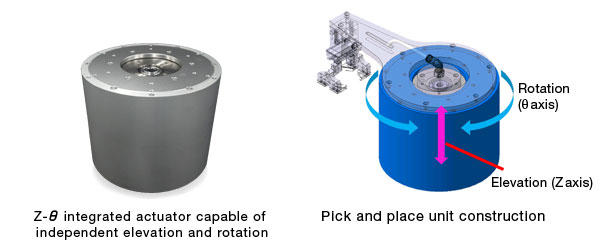

By combining a dual-axis integrated motor (on exhibit at the 2015 International Robot Exhibition), ball screw, and NSK Linear Guide™as a single unit, a compact actuator was developed that is capable of independent elevation and rotation, as well as positioning operations. This configuration makes the following complex operations possible with a single actuator: parts transfer between lines with level and direction differences and assignment of parts to multiple positions.

NSK continues to contribute to the development of environmentally friendly products in the industrial machinery field.