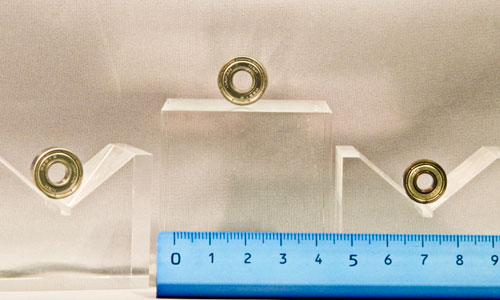

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed a ball bearing for ultra-high-speed rotary motors used in vacuum cleaner motors. This new bearing is capable of speeds in the order of 1 million dmN*1

NSK is targeting 1 billion yen in global annual sales by 2018 for this product.

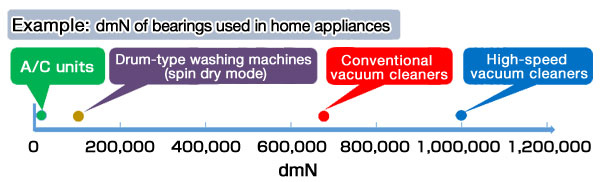

*1: dmN = (pitch diameter of rolling element in mm) × (min-1).

Approx. 650,000 dmN in bearing for conventional vacuum cleaner motors.

Development Background

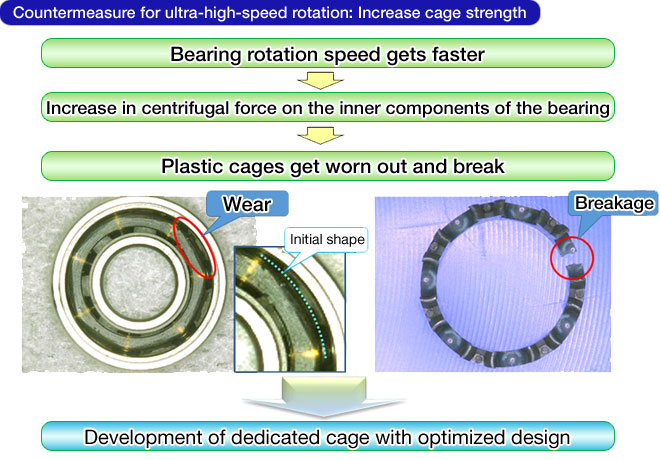

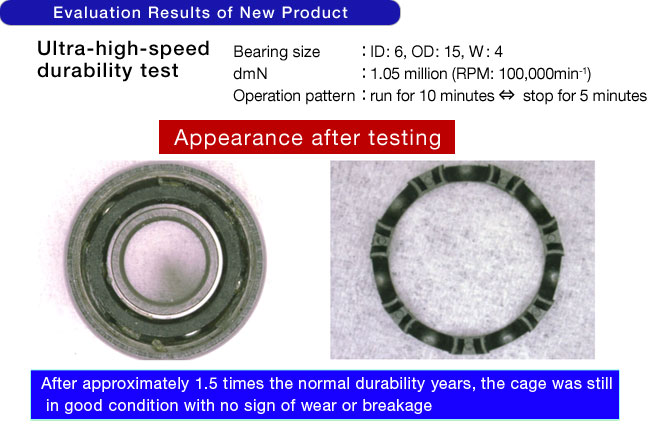

Household vacuum cleaners are getting more compact and lighter, and the air intake fans are approaching one-third the diameter of conventional ones used. In order to maintain the suction force of such-small diameter fans, the rotating speed of the fan motors has been increased, resulting in the need for the bearing being used to be able to sustain extremely high-speed rotation. In terms of dmN, a value used to indicate the speed characteristic, bearings now must be capable of withstanding in the order of 1 million dmN, which is approximately 1.5 times that of conventional speeds.

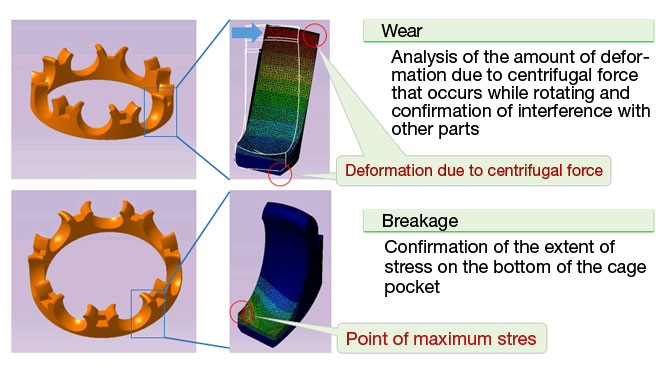

In response to this demand for bearings capable of withstanding higher speeds, NSK developed a dedicated bearing cage with an optimized design using high-strength materials. As a result, the new bearing can support ultra high speeds in the order of 1 million dmN.

Product Features

The new, high-rigidity cage that employs high-strength material and an optimized shape makes the new bearing capable of sustaining ultra high speeds in the order of 1 million dmN.

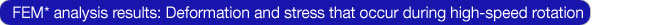

- * FEM (Finite Element Method)

- Method that solves for displacement and stress of structures by breaking down the structures into mesh elements and then using a system of equations to solve for the relation of displacement and stress for each element.

Product Benefits

This new bearing supports the ultra high speeds resulting from more compact fan motors, making it possible to realize compact, light vacuum cleaners that have a high level of suction force.