NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed a ball bearing with an excellent sealing performance for fan clutches*1 used in automobile engines.

This product, featuring a modified seal that delivers superior performance and contributes to great fan clutch reliability in markets with harsh driving environments. NSK is targeting 500 million yen in global sales of this product in 2020.

| *1: |

A fan clutch is a part incorporated into the engine’s cooling fan. It has the ability to temporarily interrupt the driving force of the engine, maintaining the optimal temperature of the automobile engine, thereby improving engine efficiency. |

Fan clutch bearings is constructed such a way that, one side is sealed by sealed fan clutch oil and other side is exposed to atmospheric side which is desired to prevent intrusion of dust, dirt and muddy water.

Current fan clutch bearings, by giving preference to integrity both sides are installed by oil sealing seal.

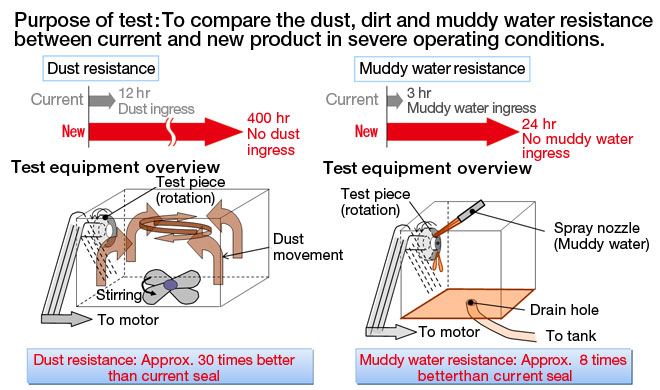

In recent years, automobiles have been used in severe environments, which adhere large amount of dust and muddy water and which causes increased seal wear. In the wear progressed region, dust and muddy water enters to bearing interior and causes abnormal noise.

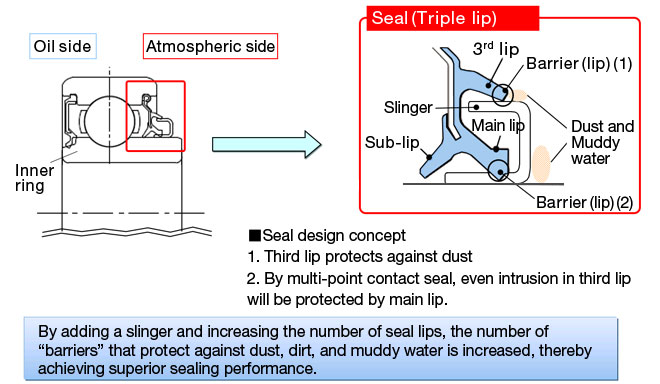

This phenomenon has resulted in a demand for a high dust and high muddy water resistant seal on atmospheric side of the bearing. NSK placed a slinger*2on the inner ring of the bearing and added a triple-layer seal lip to create a fan clutch bearing with excellent sealing performance.

*2:Slinger is a circular metal parts pressure-fitted on the inner ring of the bearing.

This product contributes to great fan clutch reliability and thereby achieve great automobile reliability in markets with harsh driving environments.