Tokyo, Japan, April 2, 2014 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a bearing with a solid lubricant coating that excels in high-temperature conditions while achieving low outgas levels and high durability.

NSK is targeting 1 billion yen in annual sales by 2015 for this new bearing, focused mainly on China, Taiwan and South Korea, which are home to the global manufacturing sites of solar cells, LEDs, etc.

Solar cells, LEDs, lithium-ion batteries and related products are manufactured in clean environments in order to attain a high level of quality and yield. The film forming and firing processes, in particular, are performed at very high temperatures, which means that grease and conventional binders,*1 such as those typically found in solid lubricant coatings, cannot be used because they cause outgas.*2 Due to this, it is necessary to replace non-lubricated bearings in most of the non-high-end equipment on a frequent basis due to their short lifespan. This situation, of course, is what prompted the need for bearings that could achieve longer life in such conditions.

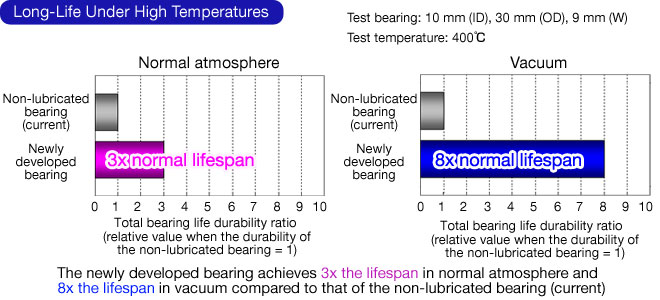

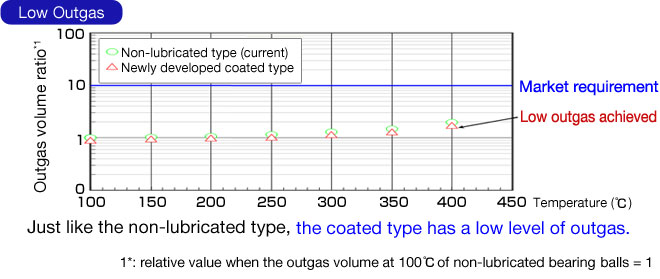

In response to this need, NSK developed a new solid lubricant coating that is applied to the bearing balls. It features superior durability under high-temperature conditions, providing up to eight times the life of the conventional type of non-lubricated bearing while maintaining the same low outgas level.

| *1. Binder: |

A bonding agent such as resin that is used to increase the adhesiveness of the solid lubricant agent to the bulk material. |

| *2. Outgas: |

Gas that is released from organic materials, etc. |

By developing a proprietary solid lubricant coating that improves adhesiveness to the bulk material without using binders that cause outgas, NSK has achieved the following features:

- Up to eight times the life of non-lubricant bearings under high-temperature conditions up to 400℃.

- Same low level of outgas as non-lubricant bearings.

This new bearing extends the maintenance interval, thereby contributing to improved productivity in high-temperature conditions such as the film forming and firing devices used in the production of solar cells.

NSK is committed to developing high-performance products to expand its SPACEA™ series in order to by meet the diverse and advanced needs of today's industries.