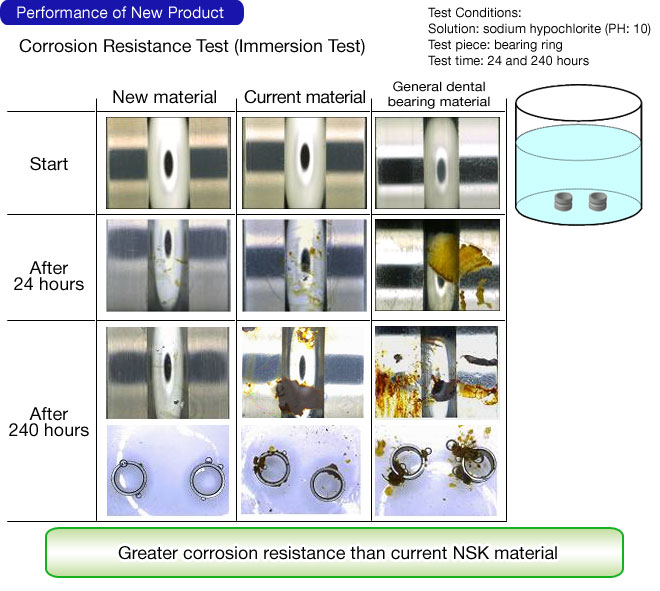

Tokyo, Japan, December 17, 2013 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a highly corrosion-resistant bearing for application in handpieces used in the medical treatment of teeth using anti-corrosive material that is superior to conventional material. This product's high corrosion resistance properties help maintain proper sanitation for dental handpieces even when immersed in highly concentrated alkaline solutions used for cleaning and sterilization.

NSK has prepared a lineup of these highly corrosion-resistant bearings and is targeting 2 billion yen a year in sales for the full dental bearing lineup by 2017.

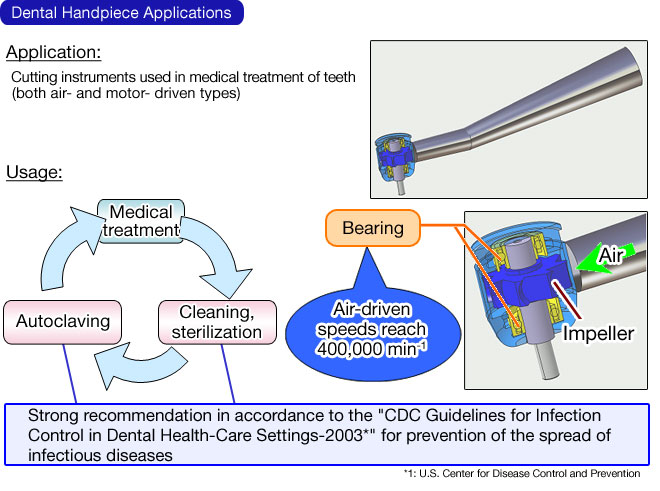

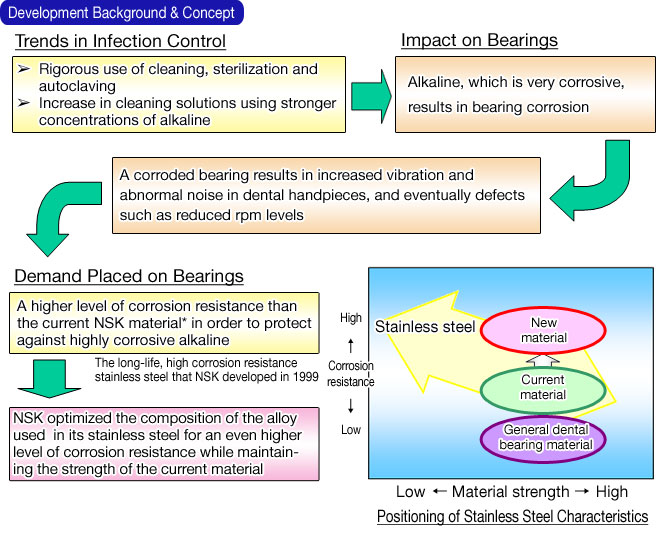

In order to prevent the spread of infectious diseases, dental handpieces are repeatedly sterilized in boiling water and disinfectant as well as autoclaved after each use. In recent years, as the awareness among patients and doctors has risen in regard to infectious diseases, a trend to use alkaline solutions to clean and sterilize these handpieces has emerged. While highly concentrated alkaline solutions are effective at sterilizing, they can lead to corrosion in the bearings, and such corrosion can then lead to reduced performance of the dental handpieces.

Although stainless material can be applied to improve the corrosion resistance of bearings, it can result in a reduction in strength. In response to this situation, NSK has developed an improved stainless bearing material that maintains fundamental performance such as strength while also achieving a high level of corrosion resistance to withstand highly concentrated alkaline antiseptics.