Tokyo, Japan, October 8, 2013 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a high-performance cartridge bearing that offers improved reliability and low friction loss for turbocharger use. NSK plans to expand the sales of this product for improved fuel economy throughout Europe and other regions, where turbocharger use is quickly expanding. NSK is targeting 3 billion yen in global sales in 2017.

In recent years there has been an urgent need to reduce emissions and improve the fuel economy of automobiles. Due to this trend, many automobile manufacturers are downsizing engine displacement for improved fuel economy. In connection with this trend, the demand for turbocharger use is expanding in order to offset the loss in engine power resulting from engine downsizing.

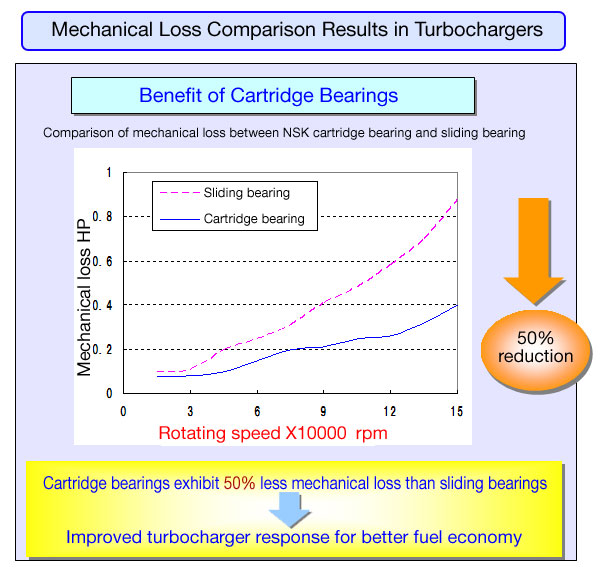

Turbochargers need to be durable enough to withstand high-temperature and high speed rotating conditions. Up until now, sliding bearings have been used for such applications. However, sliding bearings tend to have a high amount of friction loss, and this is driving the demand for rolling bearings that are highly reliable in high-temperature and high speed rotating conditions.

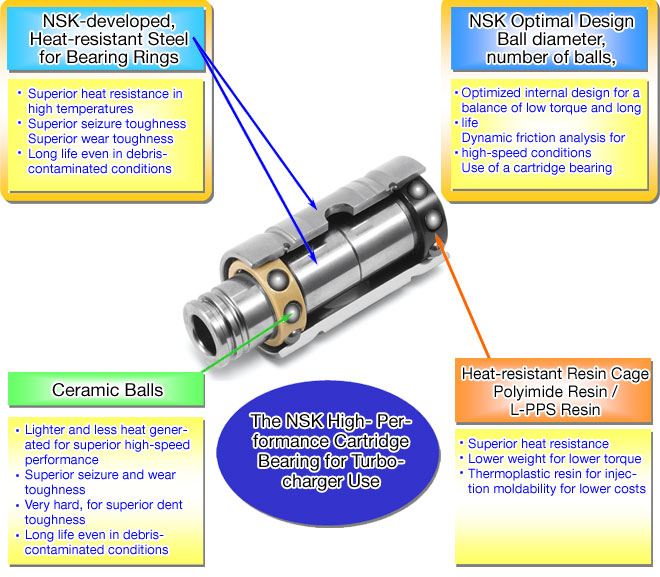

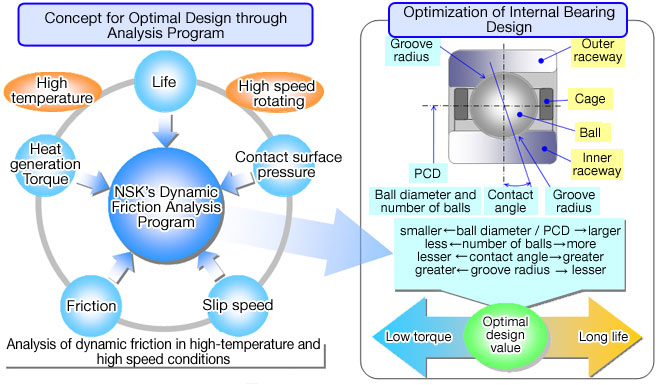

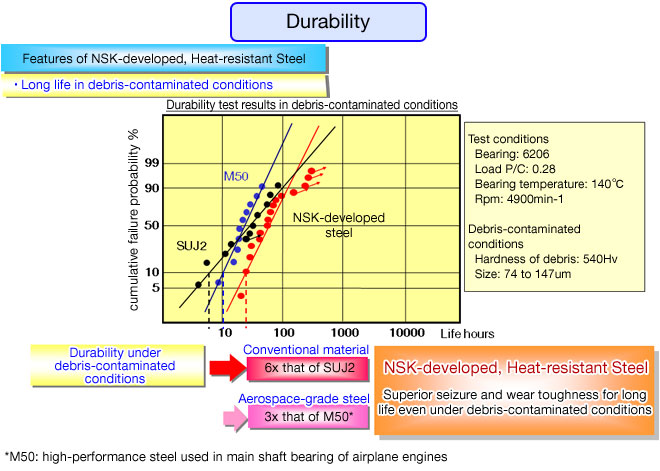

In response to this demand, NSK has optimized the internal design to develop a high-performance cartridge bearing that offers improved reliability and low friction loss.

Using this high-performance cartridge bearing will improve the response of turbochargers.

This makes it possible to further expand the use of turbochargers, thereby it will improve the fuel economy of automobiles.