Tokyo, Japan, May 31, 2011 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed low-friction ball bearings for motorcycle wheels that can lower fuel consumption by reducing friction loss significantly while maintaining conventional sealing performance. NSK will release this product mainly in emerging countries with booming motorcycle markets. The company expects to achieve global annual sales of one billion yen by 2015.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

June 1, 2011

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Develops Low-friction Ball Bearings for Motorcycle Wheels

Designed to help improve fuel consumption by reducing friction,while maintaining good sealing performance

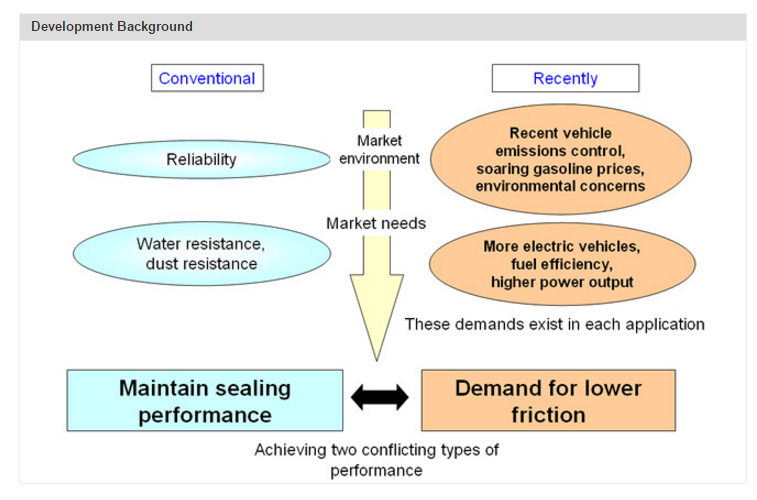

Development background

Markets where motorcycles are often used as means of transportation are continuing to grow in emerging countries. Especially in emerging countries, bearings used in motorcycle wheels must have high sealing performance to provide water and dust resistance to guarantee durability. Additionally, lowering the fuel consumption of motorcycles has become an issue recently in light of the need to comply with emissions control and because of soaring gasoline prices.

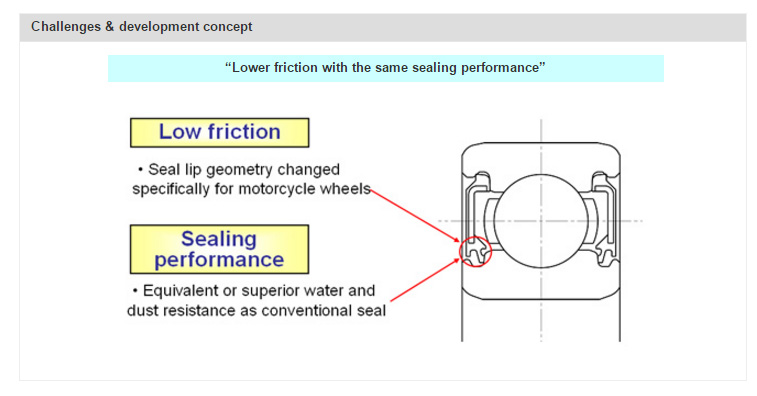

With this new product, NSK has achieved significantly reduced friction, which can lower fuel consumption, while maintaining sealing performance by applying techniques for analyzing seal geometry and simulation evaluation technology.

Product features

The newly developed product features a design specifically for motorcycle wheels, including optimized length, thickness, and geometry of the seal lip, which enables reduced friction loss while maintaining seal performance.

- ◆Reduced friction loss

- Bearing friction was reduced to about 30% by cutting the counter-force at the seal lip contact area in half.

- ◆Seal performance maintained

- The bearing's sealing performance was kept equivalent or superior by stabilizing the contact pressure at the seal lip contact area.