Tokyo, Japan, June 15, 2010 - NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) announced the release of Megatorque Motor Z Series with High Environmental Resistance, joining the Megatorque Motor family that has earned a strong reputation in the semiconductor and liquid crystal display (LCD) sectors. The new Z Series motors achieve an IP66 rating for dust and water ingress protection, making them the world's flattest and most compact direct drive motors to attain the rating. The high speed and high precision of Megatorque motors will contribute significantly to the improvement in productivity of foods and automotive components, where there is exposure to water and oil. NSK released three models of the Megatorque Motor Z Series in July 2010.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

August 5, 2010

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Releases Megatorque Motor™ Z Series with High Environmental Resistance

World's Flattest and Most Compact Direct Drive Motor with IP66 Rating*1 in Watertight and Dust-tight Performance

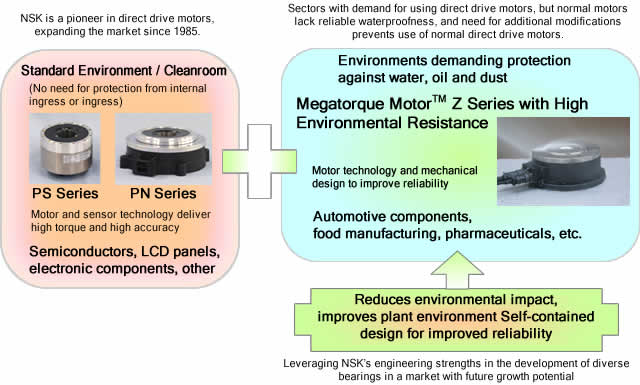

Rotary positioning mechanisms currently used in manufacturing exposed to water, oil and other liquids give priority to waterproofness, so mechanical indexing machines are widely used. However, mechanical indexing mechanisms offer limited flexibility in their installation, and have a significant environmental impact from waste oil disposal, increasing the demand for alternative solutions.

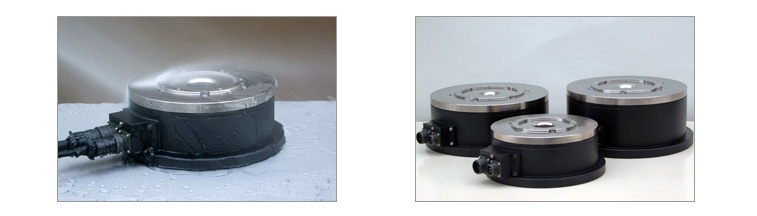

NSK developed the Megatorque Motor Z Series with high environmental resistance in order to reliably withstand manufacturing settings that involve exposure to water, oil and other liquids, as well as dust and particulates. The new Z Series motors deliver the same performance as our other Megatorque Motors, while achieving an IP66 rating for dust and water ingress protection, enabling manufacturers to significantly improve positioning speed and accuracy in a wide range of manufacturing environments.

NSK will offer expanded after-sales service to ensure the long and reliable use of the motors by customers. The service includes the assessment of waterproof seal life, in addition to a range of maintenance, replacement and repair services.

The Megatorque Motor Z Series with high environmental resistance has been available since July 2010. NSK expects the sales of this product to reach one billion yen by 2012. NSK showcased the Megatorque Motor Z Series in Tokyo at the 23rd Interphex Japan trade show held from June 30 to July 2, 2010, and at the Techno-Frontier 2010 trade show held from July 21 to 24, 2010.

Megatorque Motor™ Z Series - Features and Benefits

- World's first direct drive motor with IP66 rating*2

-

Original waterproof construction protects the direct drive motor from ingress against high pressure water jets, achieving an IP66 rating for ingress protection under IEC standards.

- Benefits for Customers:

- Suitable for processing and washing machines for automotive components, and manufacturing machines for foods and medical containers, in settings where there is exposure to water, oil and other liquids, as well as dust and particulates, either from spray, leakage or dispersion.

- World's flattest and most compact direct drive motor with dust and water ingress protection

-

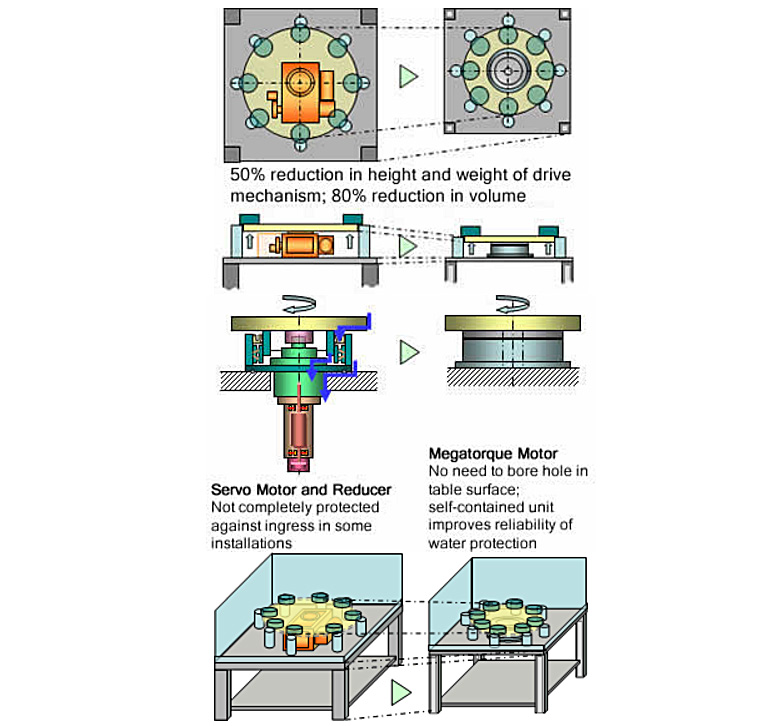

Technologies for high precision and high torque of Megatorque Motors are integrated with a flat design and excellent sealing to set a standard as the world's flattest and most compact (based on volume/torque ratio) direct drive motor with water ingress protection.

- Benefits for Customers:

- Compared with using a mechanical indexing machine under exposure to water and oil, the Megatorque Motor Z Series reduces the drive mechanism height by 50% and is approximately 80% smaller in volume, to significantly reduce the equipment size.

- High torque and high precision for improved productivity

-

The motor is available in three models rated for a maximum output torque of 40 N・m, 130 N・m and 175N·m respectively, to support a wide range of load. All models deliver a repeatability of ±2 seconds (1/1800 degrees) with a position sensor resolution of 2.62 million pulses/revolution.

- Benefits for Customers:

- Customers who demand faster positioning can easily choose a model from the Megatorque Motor Z Series, instead of a mechanical indexing machine. The high speed and highly accurate positioning delivered by Megatorque Motors will significantly improve productivity and quality.

- Environmental benefits and resource conservation

-

- Reducing the use of environmentally harmful substances:

- EU RoHS directive compliant, signifying less environmental impact

- Low waste:

- Eliminates need for waste oil disposal currently necessary when using mechanical indexing mechanisms.

- Resource and energy savings:

- Reduces the size of the drive mechanism and the amount of materials used for the overall equipment. Enables more compact table diameter to reduce energy needed for conveyance.

About Megatorque Motors

NSK first introduced a line of direct drive motors using the Megatorque Motor trade name in 1985. Direct drive motors eliminate the vibration and backlash that is associated with a servo motor and reducer, or a mechanical indexing machine. Compared with other direct drive motors, Megatorque Motors are compact and flat, combined with their high torque and high accuracy, Megatorque Motors deliver unique value that customers have come to rely on. Megatorque Motors are used in a wide range of applications, such as actuators in factory automation ranging from semiconductor, LCD, and CD/DVD manufacturing machines to assembly and inspection equipment.

Conformity to Underwriters Laboratories Standards and EC Directives (CE Markings)

- Megatorque Motor™ Z Series with High Environmental Resistance

- Megatorque Motor Z Series does presently not comply with UL Standards and CE Markings. If conformity is required, please contact NSK.

- EDC Driver Unit

- The EDC Driver Unit complies with Underwriters Laboratories (UL) Standards and CE Markings only when used with a standard specification Megatorque Motor PN Series motor (no brake). The EDC Driver Unit does not comply with UL Standards and CE Markings when used with Megatorque Motor Z Series.

*1 The IP66 rating, defined by the International Electrotechnical Commission (IEC), classifies the degree of protection against ingress of foreign material (dirt, dust and water). Megatorque Motor Z Series is the flattest and most compact direct drive motor to be certified with IP66 rating (as of June 2010, based on data collected by NSK)

*2 Certified by third party testing agency TÜV Rheinland Japan Ltd. under IEC 60529 and IEC 60034-5 standards.

1. Megatorque Motor™ Z Series (PNZ Model ) Specifications

| Reference number | ||||

|---|---|---|---|---|

| Functional item | M-PNZ3040KN001 | M-PNZ4130KN001 | M-PNZ4175KN001 | |

| Motor outer diameter | [mm] | φ220 | φ286 | |

| Maximum output torque | [N·m] | 40 | 130 | 175 |

| Motor height | [mm] | 100 | 120 | 137 |

| Motor hollow diameter | [mm] | φ44 | φ37 | |

| Maximum rotationa speed |

[s-1] | 3 | ||

| Resolution of position sensor |

[counts/rev] | 2,621,440 | ||

| Absolute positioning accuracy |

[arc sec] | 90 (interchangeable type, ambient temperature: 25±5[°C]) | ||

| Repeatability | [arc sec] | ±2 | ||

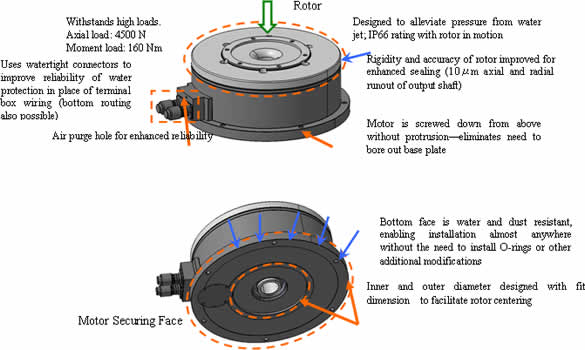

| Allowable axial load | [N] | 4,500 | 9,500 | |

| Allowable moment load | [N·m] | 80 | 160 | 200 |

| Mass | [kg] | 21 | 42 | 48 |

| Environmental conditions | Ambient temperature 0-40[°C]; use indoors, free from corrosive gas | |||

| Degree of Protection | IP65, IP66 (IEC/EN 60529, IEC/EN 60034-5) | |||

2. Degree of Protection Provided by Megatorque Motor™ Z Series (PNZ Model)

IP codes are defined in IEC 60529, which classifies the degree of protection against the ingress of foreign material (dirt and dust, water) into the enclosure of electrical and mechanical products. The first digit (0 to 6) indicates the level of protection against ingress of solid objects such as dust, and the second digit (0 to 8) indicates the level of protection against water ingress (waterproofness).

Summary of Testing Conditions and Assessment Method for Protection Classifications

IP6X: Totally protected against dust, after eight hours in talc powder (75μm filter) and internal pressure reduced to 2kPa.

IPX5: Protected against a low-pressure jet of water, must withstand for at least three minutes while being subjected to the jet using a φ6.5 spray nozzle diameter at a rate of 12.5ℓ/min from all directions, using a φ6.5 spray nozzle diameter at a rate of 12.5ℓ/min.

IPX6: Protected against temporary flooding with water, must withstand for at least three minutes while being subjected to a powerful jet of water using a φ12.5 spray nozzle diameter at a rate of 100ℓ/min from all directions.

Dust and water resistance testing do not constitute a guarantee against malfunction or accident, or a guarantee of the product life. IP classifications specified by the IEC constitute indexes for protective performance under fixed conditions, and do not constitute a guarantee of ingress or ingress protection in all conditions and for all liquids and solids.

3. Replacement with Megatorque Motor™ Z series (PNZ Model)

(1) Reduces the overall equipment size and weight, compared with using a mechanical indexing machine.

Example: (Oil used for processing work)

A table measuring φ800 mm due to the size of indexing machine can be reduced to φ550 mm, and the weight reduced by 30 kg. The transfer time can also be reduced by 60%, from 1.5 seconds to 0.6 seconds.

(2) The Megatorque Motor provides contained water protection, to significantly improve reliability when compared with a non-contained unit.

World's flattest design enables drop-in replacement for existing machinery.

4. Dust and Water Resistant Construction of Megatorque Motor™ Z Series (PNZ Model)

5. Demand for Megatorque Motor™ Z Series with High Environmental Resistance