Tokyo, Japan, October 6, 2010 - NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced it has developed a next-generation tapered roller bearing featuring a plastic cage design and lower friction loss. NSK will market the new bearing, intended for the drivetrain*1 market, as a high-performance fuel efficiency product that enhances its product lineup, and is targeting annual sales of 1 billion yen by 2015.

*1: Drivetrain: Includes such devices as transmissions, transfer cases, and differentials

Development Background

There has been growing demand in recent years for higher efficiency bearings featuring lower friction loss; for example, those that can meet demand for transmissions that contribute to greater fuel efficiency in automobiles. Also in demand are transmission bearings capable of performing under very severe lubrication conditions. This includes operating with low viscosity transmission fluids that offer the benefit of lower agitation resistance as well as improving the very sparse bearing lubrication condition that occurs during oil pump shut down in the electric-motor-only mode in hybrid vehicles.

Product Features

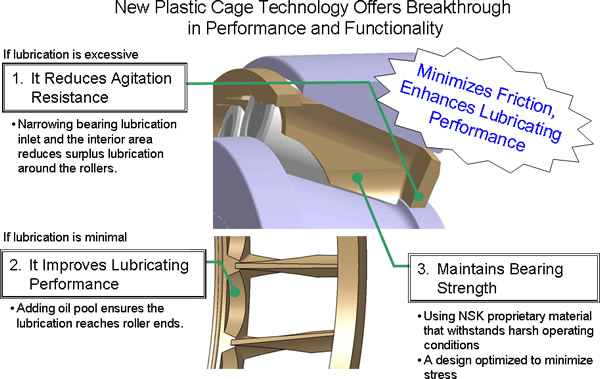

The new tapered roller bearing features a plastic cage specially designed by NSK. The properties of the plastic enable the creation of more intricate shapes that offer the following advanced characteristics:

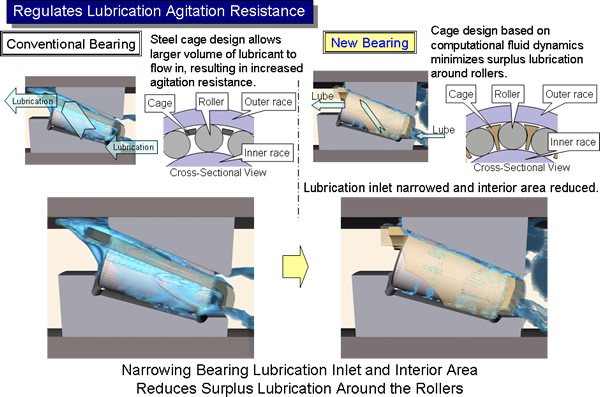

- Being able to minimize the interior space requirements of the bearing helps prevent inflow of any surplus volumes of lubricant. This in turn helps reduce agitation resistance.

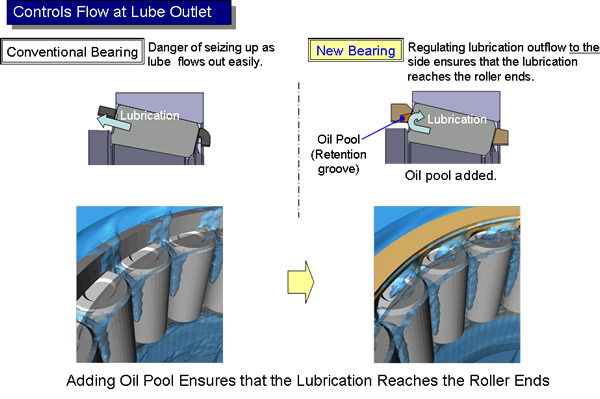

- Adding an oil pool ensures a stable supply of lubricant to the sliding surfaces of the rollers, thereby improving lubricating performance.

- Use of NSK proprietary analysis technology ensures strong cages.

- To fully meet the various demands of operating conditions and applications, the new tapered roller bearing with plastic cage comes in three designs. These include the polyamide 66 and polyamide 46 types and the linear polyphenylene sulfide (L-PPS)type with special additives and a high temperature-resistant design.

Product Benefits

- Friction reduced by 20% compared with existing products.

- Capable of operating with low-viscosity lubrication and under very low volume lubrication conditions.

- Higher reliability.

Development Features

Reduces Agitation Resistance (Feature #1)

Improved Lubricating Performance (Feature #2)