Tokyo, Japan, October 18, 2010 — NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced it has developed a new addition to its lineup of NSK Linear Guides™, the Roller Guide Equipped with High-Performance Side Seals. The new roller guides feature enhanced durability under harsh operating conditions where lubrication tends to dry out or become contaminated by dust. NSK will start selling the new roller guide series in March 2011. The company targets annual sales of 3 billion yen for the roller guides market overall by 2012.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

November 11, 2010

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Adds New Roller Guide Equipped with High-Performance Side Seals to NSK Linear Guides™ Lineup

Newly Developed, High-Performance Side Seals Help Extend Service Life Under Dusty Operating Conditions

Development background

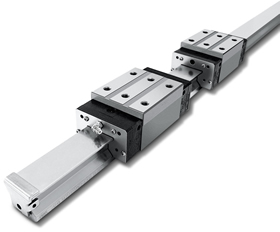

Roller guides feature both high rigidity and large load capacity, which is why they are utilized in a wide range of applications, mainly in the area of machine tools. However, because fine dust particles can force their way into the roller guide slider, abnormal abrasion of the raceway and impairment of the rotation of the rolling element can occur. Conventional roller guides used in production environments that generate fine dust particles can even become damaged in a relatively short time.

While conventional roller guides are enclosed by covers designed to prevent direct penetration by dust particles, the covers fail to completely prevent particle penetration. This has made it necessary to improve the dustproof performance of the roller guide itself. The challenge has been to find ways to extend the life of the roller guide side seals.

NSK's new igh-performance side seals now make it possible to maintain highly dustproof performance in roller guides for very long periods of operation.

NSK is planning to exhibit the new roller guide at the 25th Japan International Machine Tool Fair (JIMTOF2010) to be held from October 28 to November 2 at Tokyo Big Sight in Tokyo.

Product features

The new Roller Guide Equipped with High-Performance Side Seals employs the following advanced features that prevent the entry of fine dust particles, making it ideal for operating under harsh conditions, including extremely dry environments and those that generate very fine dust particles. This is done by minimizing penetration of foreign matter into the roller guide itself, which realizes long service life.

- Highly dustproof performance

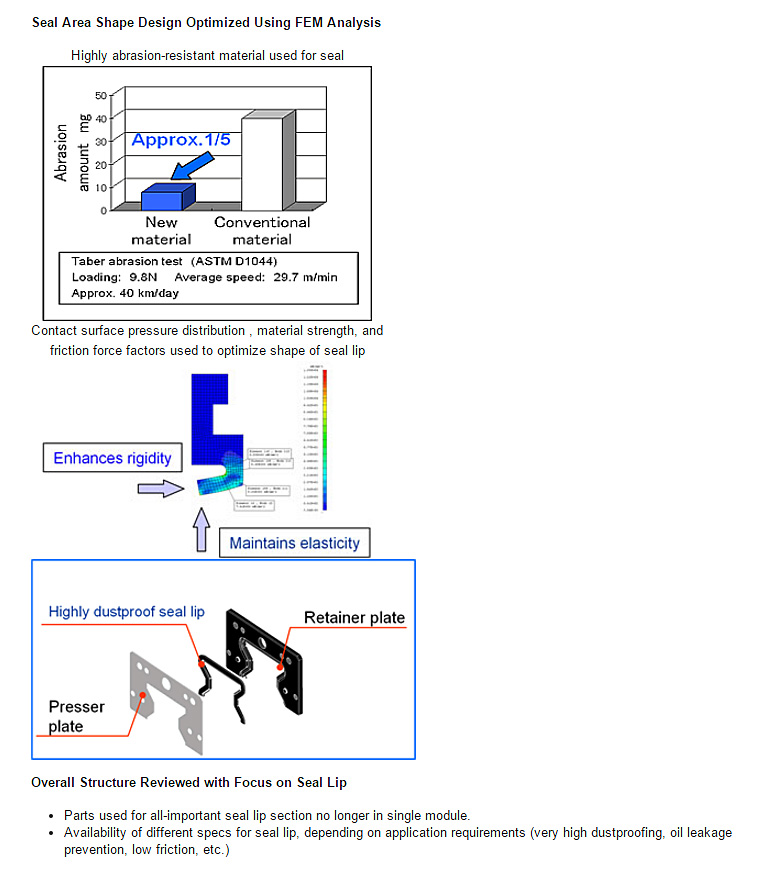

- Incorporating highly dust resistant side seals designed using new materials and a new shape that improves abrasion resistance makes it possible to prevent penetration by particles not stoppable with conventional cover designs.

Adding the rail cover prevents buildup of foreign matter in the mounting bolt holes, thereby helping to prevent dust entry into the inside of the roller guide. - Enhanced durability

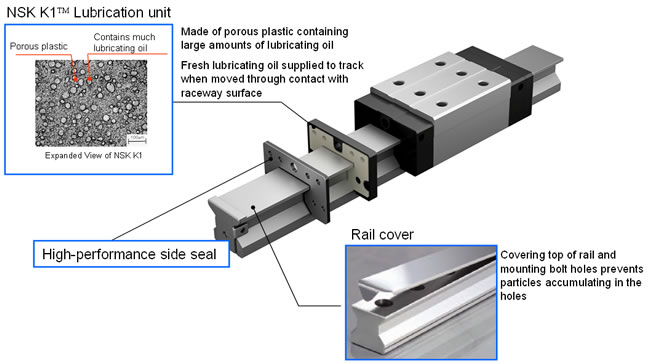

- The new high-performance side seals boast abrasion-resistance performance more than five times that of conventional products, ensuring dustproof performance can be maintained over very long periods. In addition, NSK K1™ Lubrication Unit improves roller guide track surface and side seal area lubrication performance, which helps to minimize any tear-off of the side-seal lip.

Sample applications

The new Roller Guide Equipped with High-Performance Side Seals is ideal for use with the types of machine tools that operate under the highly dust generating conditions of graphite, sintering and ceramics production environments.

Environmental considerations

The new Roller Guide Equipped with High-Performance Side Seals is an environmentally friendly product that includes no materials considered environmentally harmful substances and features significantly enhanced product durability. It also contributes to lower resource consumption.

Specifications of High-Performance Side Seal

Main Specifications for Roller Guide Equipped with High-Performance Side Seals

Rail Cover and the NSK K1™ Lubrication Unit Come Standard

Target Applications and Applicable Models

Applications

Suited to graphite, sintering and ceramics processing machine conditions that generate high volumes of dust.

- Examples of Products:

- Graphite: electrical discharge machined electrodes (in die processing)

Sintered alloys: automotive parts

Ceramics: ceramic screws (for medical and electronic device applications)

Applicable Models

RA Series Roller Guides: RA35, 45 and 55

- Will be included in lineup of optional parts for RA series roller guides.