Tokyo, Japan, September 29, 2009 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) has developed new cages and rollers for planetary gear mechanisms (hereinafter referred to as “planetary gears”) for use as cages and rollers for miniature planetary gears with high-speed rotation specifications. NSK expects annual sales to reach 2.5 billion yen by 2015 given that these products meet the need for miniaturized, lighter-weight, higher-output belt CVTs, ATs, and hybrid vehicle transmissions.

In recent years, an increasing number of ATs have employed multistage gears for up to eight speeds within a compact space to mitigate shocks caused by gear changes and improve the power transmission efficiency to achieve a reduction in CO2 emissions and higher fuel economy In addition, high-speed rotation that can generate higher output with smaller motors for hybrid vehicles is being developed. Given this, there is demand for not only high-speed rotation, but also a reduction in the size and weight of the cages and rollers used in planetary gears to change gear speeds and transmit the torque in transmissions. NSK is contributing to improved fuel efficiency in vehicles and thereby reducing CO2 emissions and improving the efficiency of gear speed changes by developing these products with the following features.

Features of cages and rollers for miniature planetary gears.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

October 19, 2009

日NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Develops Miniature New Cages and Rollers for Planetary Gears with High-speed Rotation Specifications

Designed to Reduce the Size and Improve the Efficiency of Automobile Transmissions

Product features

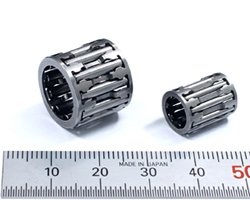

- World's smallest cages and rollers for planetary gears

- NSK has succeeded in developing the world's smallest cages and rollers for planetary gears (with a roller diameter of 1.5 mm and a planetary shaft diameter of 7 mm) by adopting a high-strength M-shaped retainer. This reduces the size and weight of belt CVTs, ATs, and hybrid vehicle transmissions.

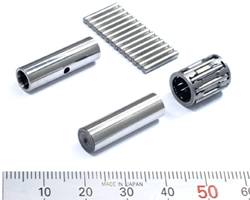

- Rotation at a speed 1.5 times higher than conventional cages & rollers

- NSK has realized a limit rotation number that is 1.5 times higher than that of conventional products by adopting nitrocarburized high-strength chrome molybdenum steel for the retainer and reducing retainer thickness to 80% that of conventional models. This contributes to higher-speed rotation for ATs and hybrid vehicle transmissions. In addition, the service life has been extended beyond that of conventional products by increasing the length of the roller by approximately 5%.