9.2—Oil Lubrication

Compared to grease, oil lubrication better suits high-speed rotation, effectively provides cooling, and more easily allows for total lubricant replacement. The superior lubricating power of oil also extends bearing life.

Oil Lubrication Methods

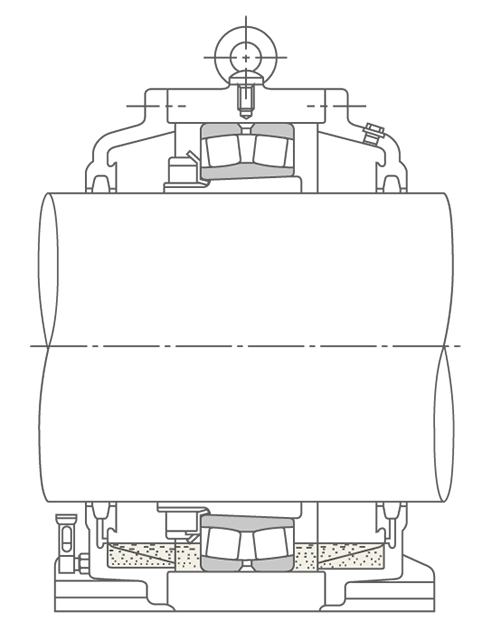

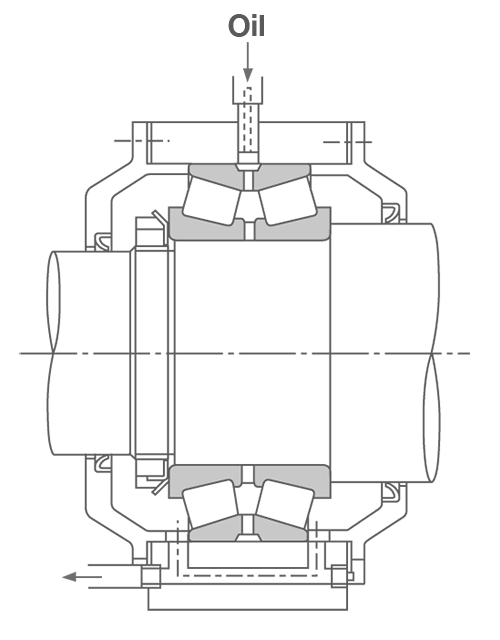

Oil Bath

A common lubrication method used under low and medium speeds.

Generally, the oil level is held up to the center of the lowest rolling element.

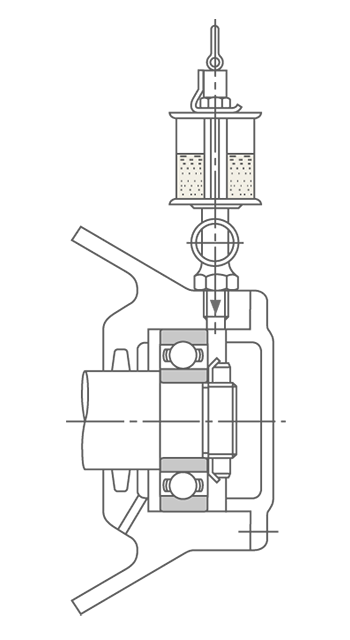

Drip Feed

A method often used for small ball bearings rotating at relatively high speeds. Oil is fed to the bearing from a visible oiler.

Splash

Rather than direct immersion, oil is splashed onto the bearing by surrounding gears, rotating rings, etc.

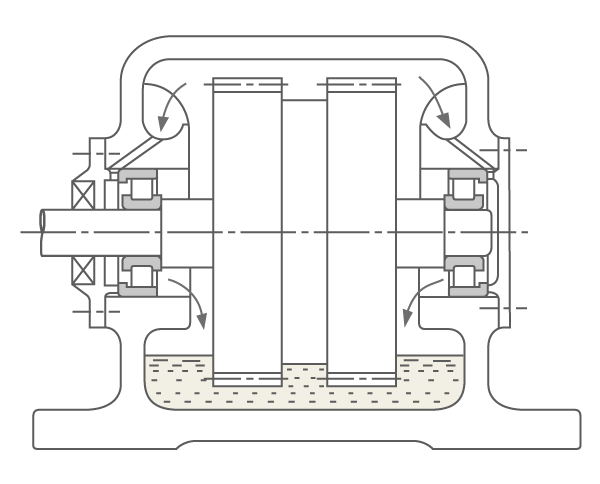

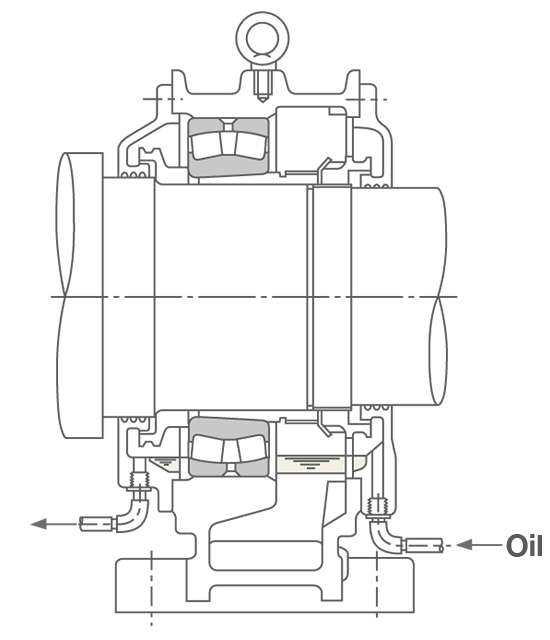

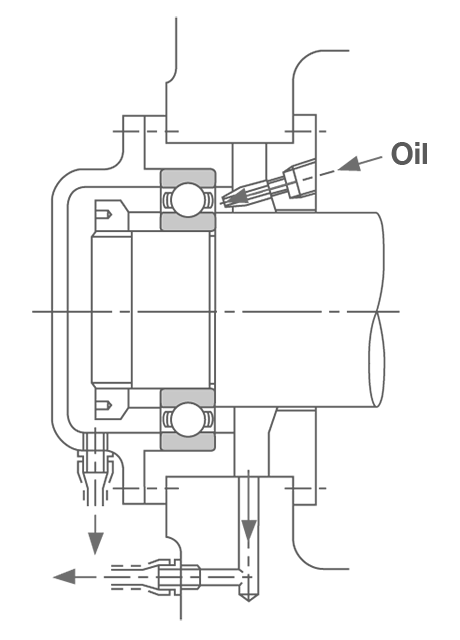

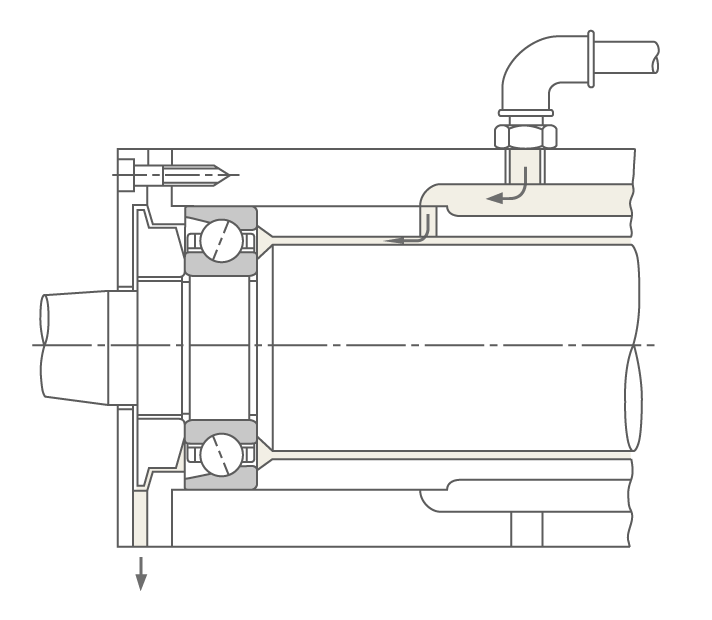

(Forced) Circulation

A method for high-speed applications that require bearing cooling or environments with high ambient temperatures.

In example (a), oil returns to a tank from a discharge pipe once a set amount of oil accumulates in the system. In example (b), oil is not stored, but rather recirculates through a pump and filter. In both, the discharge pipe is larger than the supply pipe to prevent too much oil from accumulating in the housing.

Example (a)

Example (b)

Jet

A method often used for high-speed bearings, such as those used in jet engines, where the dmn value (rolling element pitch circle diameter [mm] × rotation speed [min-1]) exceeds 1,000,000. Oil is sprayed directly into the bearing.

Oil-Mist

A method that uses air to atomize the oil and spray it on the bearings. The small amount of oil used keeps stirring resistance low, suiting high-speed bearings.

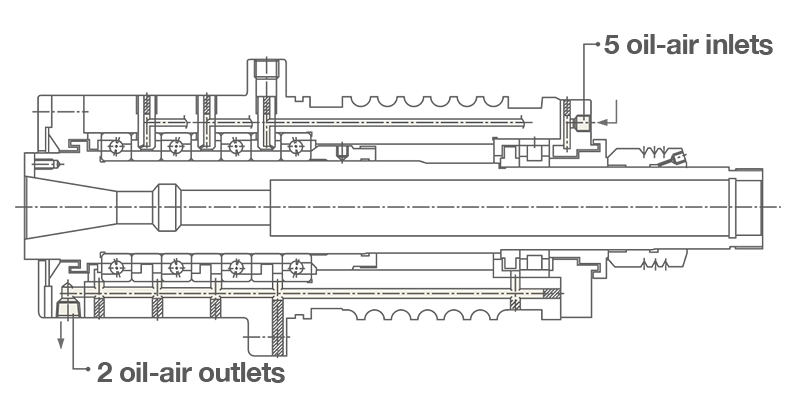

Oil-Air

A method that intermittently dispenses a very small amount of oil with a metered piston into a mixing pipe with a constant flow of compressed air to provide a continuous supply of lubricant.

Often used in machine tools, the constant supply of compressed air creates high internal pressure inside the spindle that helps prevent the entry of dust and cutting fluid.

Comparison of Lubrication Methods

◎: Excellent, ○: Good, △: Fair, ×: Poor

| Lubrication Method | Reliability | Frictional Torque | Temperature Rise | High speed | Cost | |||

|---|---|---|---|---|---|---|---|---|

| Oil Film Stability | Lubricant Life | Resistance to Foreign Matter | ||||||

| Grease | △ | △ | × | ◎ | 〇 | 〇 | ◎ | |

| Oil | Oil bath | 〇 | 〇 | △ | × | × | × | 〇 |

| Drip-feed | △ | 〇 | △ | △ | △ | △ | 〇 | |

| Splash | △ | 〇 | △ | △ | △ | △ | 〇 | |

| Forced circulation | ◎ | ◎ | ◎ | × | ◎ | 〇 | △ | |

| Jet | ◎ | ◎ | ◎ | × | ◎ | ◎ | × | |

| Oil-mist | △ | ◎ | 〇 | 〇 | 〇 | 〇 | △ | |

| Oil-air | 〇 | ◎ | ◎ | 〇 | 〇 | ◎ | △ | |

Oil Change Intervals

Oil change intervals vary based on operating conditionns, the amount of oil, and so on:

- Generally, if operating temperature is below 50℃ and lubrication conditions are good with clean lubricant, oil can be changed once per year.

However, if the oil temperature reaches 100℃, then oil should be changed every 3 months or sooner.

- If the oil is mixed with water or foreign matter, it will need to changed even sooner.

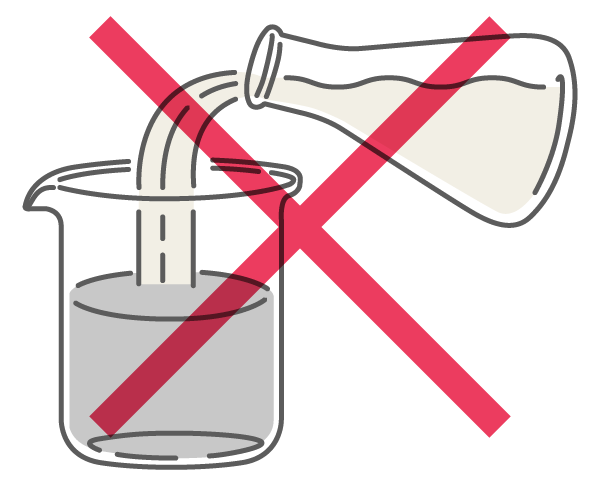

Just as with grease, as the compositions of different oils can differ, different oil brands must not be mixed.

Never mix oils of different brands/types.