10.1—Mounting

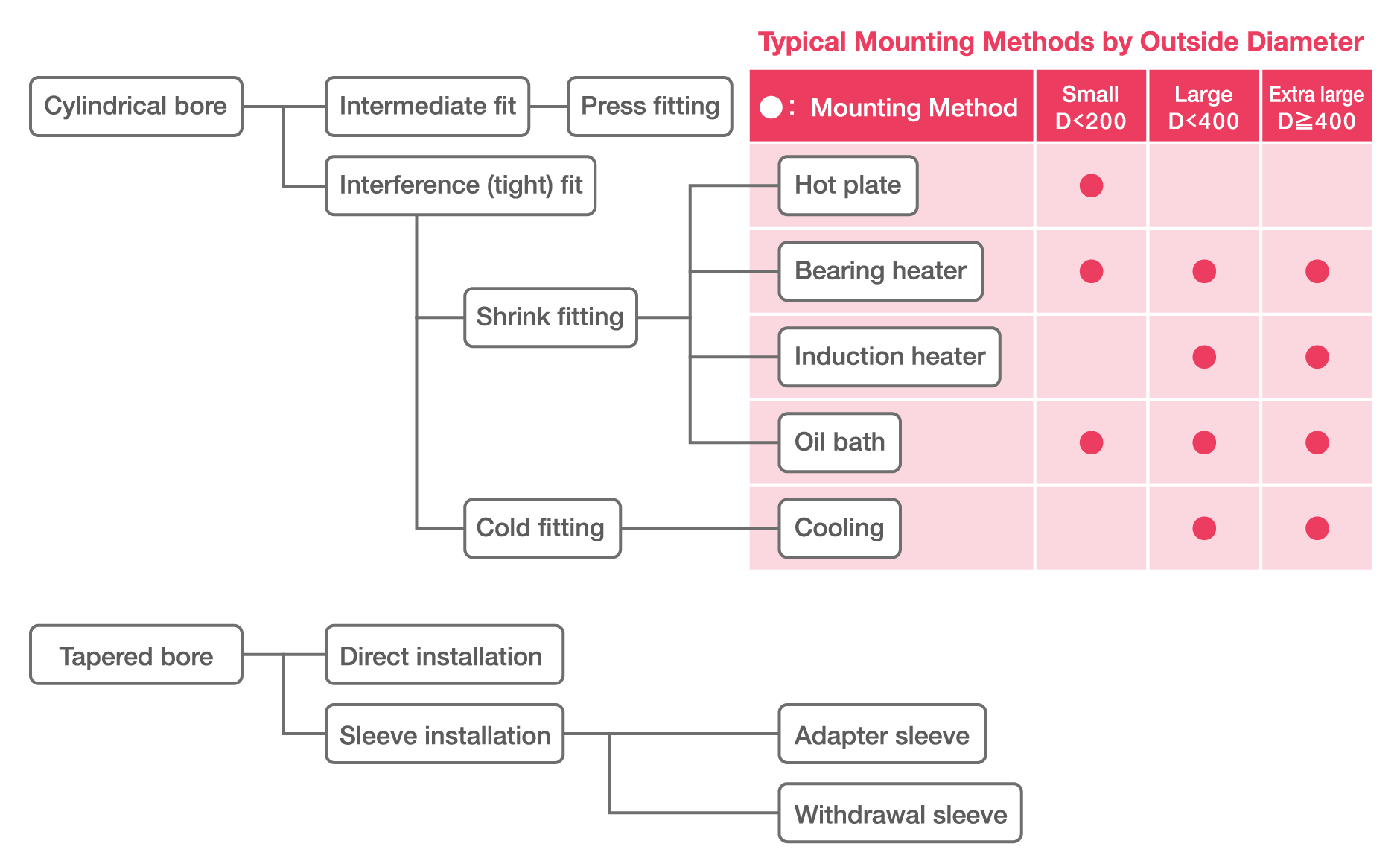

Bearings can be mounted in different ways depending on their type, size, and fit.

Incorrect mounting often results in bearing damage and shorter equipment life.

Mounting Workflow

Bearing mounting strongly affects accuracy, life, and performance. Therefore, designers and mounting technicians must thoroughly consider all aspects related to mounting when creating standards and procedures.

Typical Mounting Procedures

1. Cleaning

2. Check of Dimensions/Finishing

3. Mounting

4. Inspection

5. Lubrication

6. Running Test

Bearings should only be unpacked immediately prior to mounting.

Cleaning Bearings and Related Parts

Typically, grease-lubricated bearings do not require cleaning before being filled with grease.

Additionally, sealed bearings come pre-packed with grease and are used without cleaning.

Even when using oil lubrication, cleaning is not usually required. However, if the bearing is used in a sensitive instrument or at high speeds, it should be cleaned with washing oil to remove any anticorrosives (e.g., rust-preventive oils).

Once the anticorrosive is removed, the bearing should be used right away. Do not store bearings after removing the anticorrosive as rust can develop easily.

Mounting Methods

Bearings can be mounted in a variety of ways, depending on the fit and type/size of the bearing.

Warnings

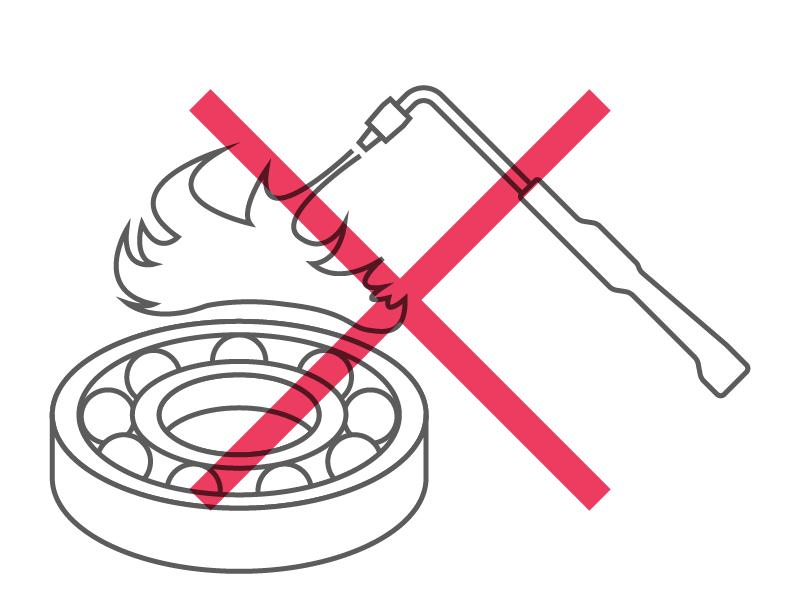

Do not use open flames near bearings.

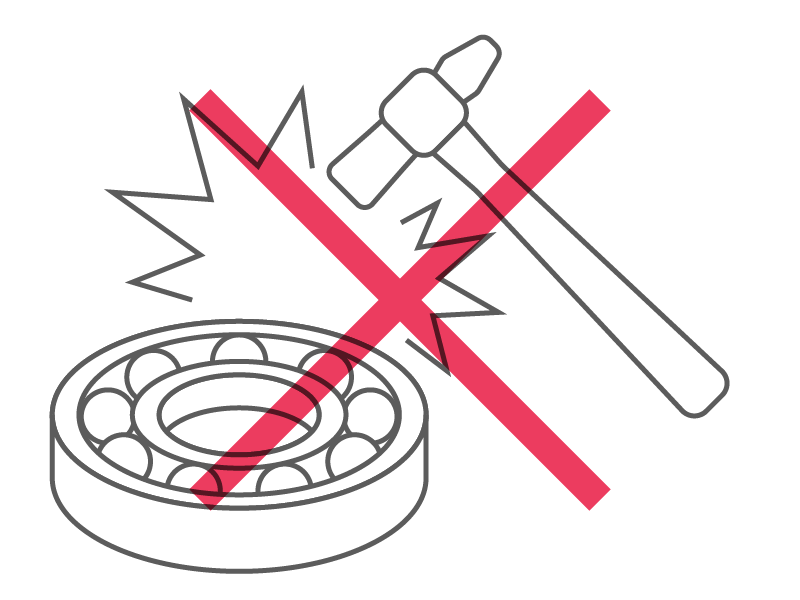

Do not strike bearings directly.

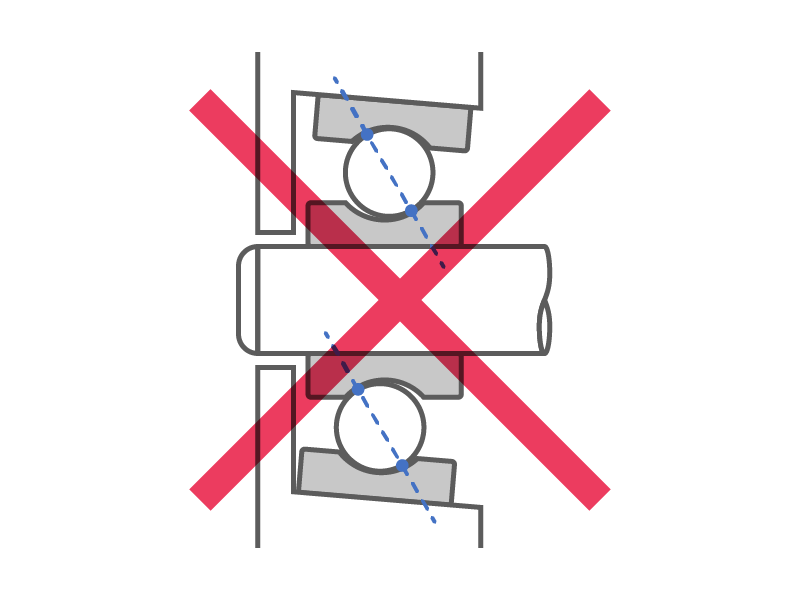

Avoid misalignment.

Do not mount to a sloped housing bore surface.

Do not tilt the inner ring.

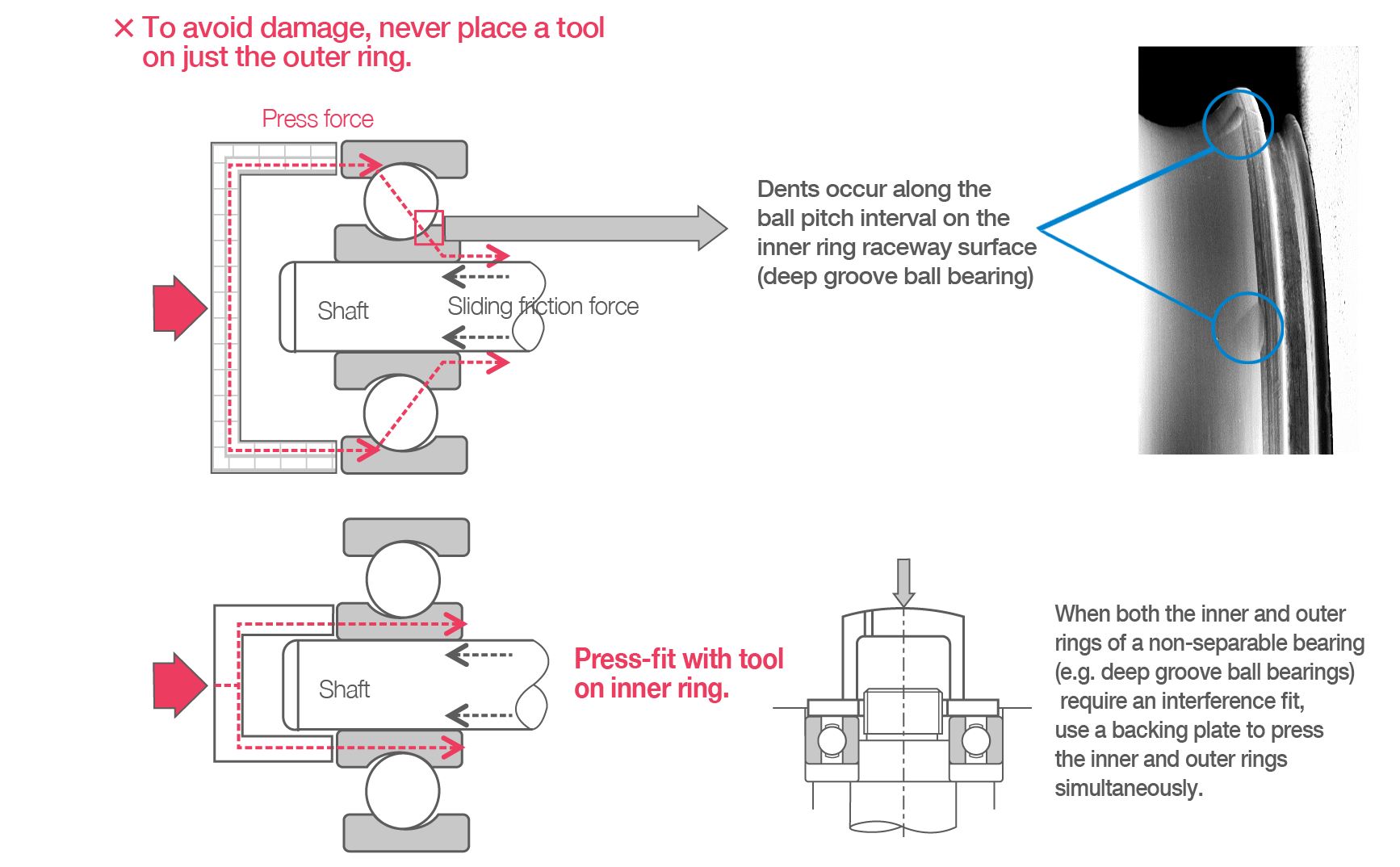

Mounting Precautions (Press Fits)

Shrink Fits (Hot Mounting)

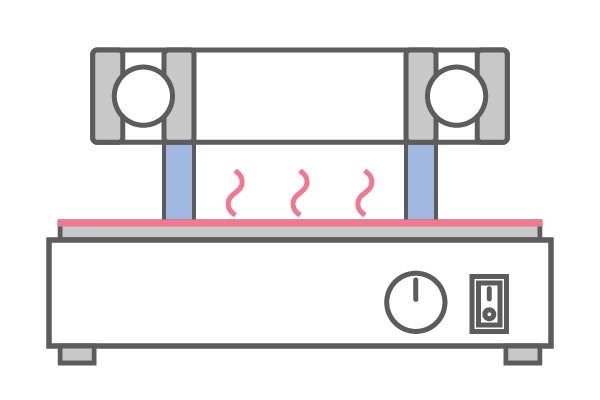

1. Hot Plate

Do not place directly on the plate.

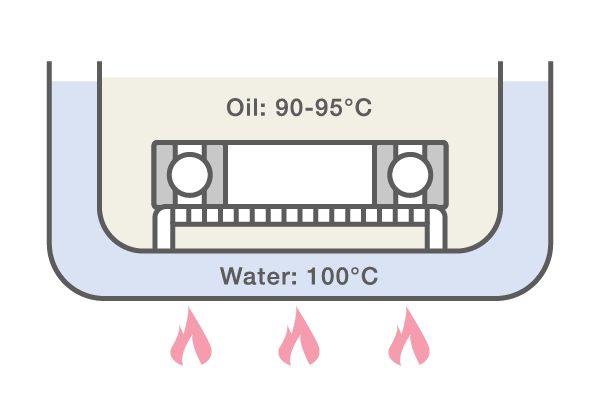

2. Oil Bath

Do not place at the bottom of the tank.

3. Bearing Heater

Hold the bearing firmly in place for 5 to 10 seconds while heat dissipates to ensure there is no clearance between the bearing and shaft shoulder as it shrinks (take appropriate measures to prevent burns).

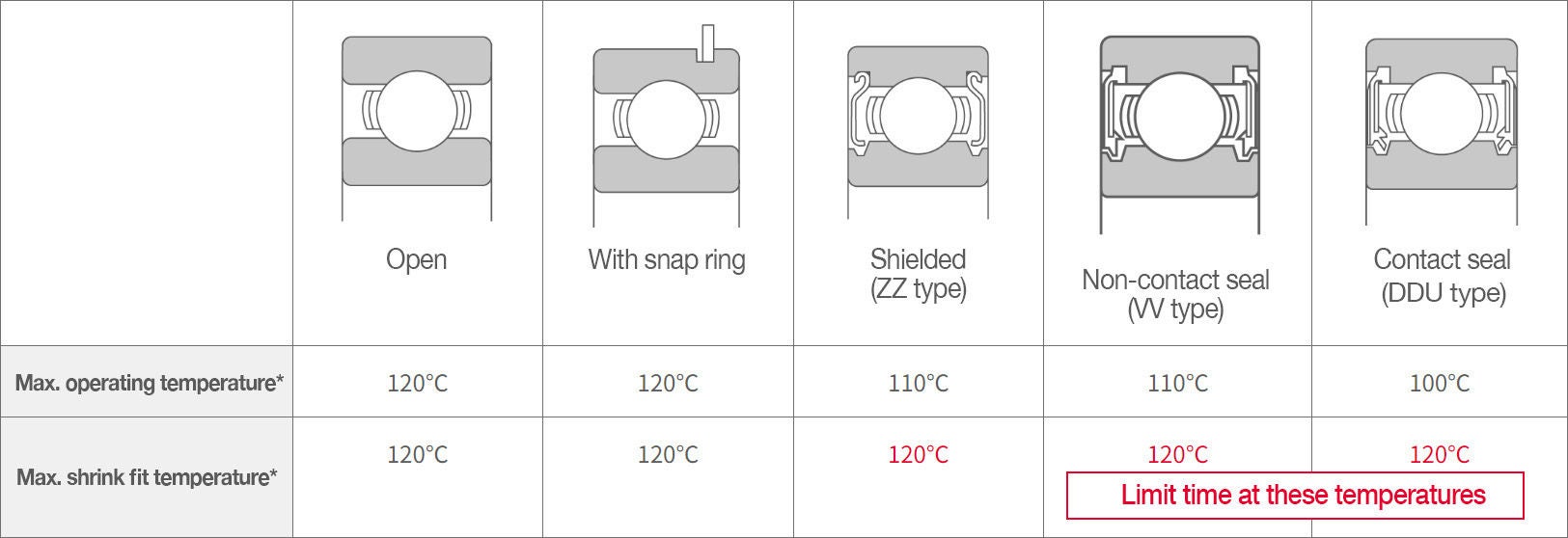

When heating sealed bearings, do not keep them at high temperatures for long periods.

Note that grease deteriorates rapidly under high temperatures

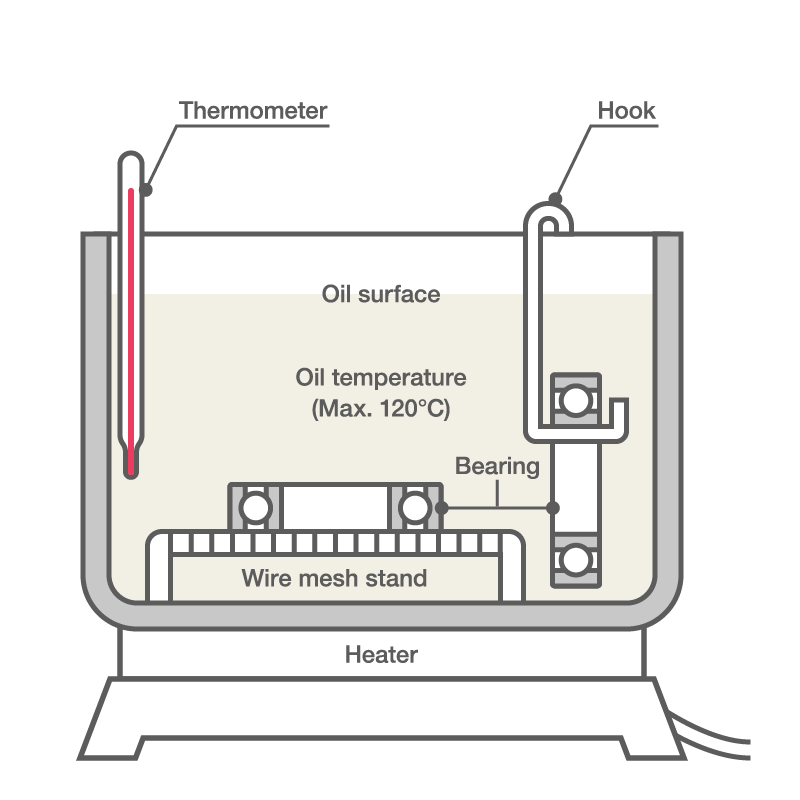

Oil Tank Heating

- It is difficult to press fit large bearings due to the amount of force required.

Therefore, large bearings often use shrink fits. After the bearing is heated in oil and expands, it is mounted on the shaft where it cools and contracts. - This method does not apply undue force to the bearing and allows for quick mounting.

- Take the following precautions when performing shrink fits:

- Do not heat bearings above 120°C for long periods.

- To prevent localized heating, place the bearing on a wire mesh or hang it on a hook so that it does not directly touch the bottom of the oil tank.

- Heat the bearing to a high enough temperature to prevent it from causing difficulties as the inner ring cools during mounting.

- The bearing will also shrink widthwise as it cools after mounting. Use a suitable method such as a shaft nut to keep the bearing in place and prevent a clearance from developing between the inner ring and shaft shoulder.

Induction Heaters

In addition to oil-based methods, bearing heaters using electromagnetic induction are widely used to heat bearings.

- Bearing heaters use a coil to produce an inductive current that generates heat within the bearing from its own resistance.

- Bearing heaters provide uniform heating in a short time without flames or oil, making the work of shrink fits more efficient and clean.

- Using a dedicated induction heater for mounting and dismounting inner rings is especially useful when such work is performed relatively frequently, such as with the roller bearings of rolling mill roll necks and railway axles.

Bearing heater

Induction heater

Shrink Fit Temperatures for Deep Groove Ball Bearings

*Temperatures above are a guideline for standard bearings. If possible, keep bearings below the max. operating temperature even when fitting.

Cool Fits

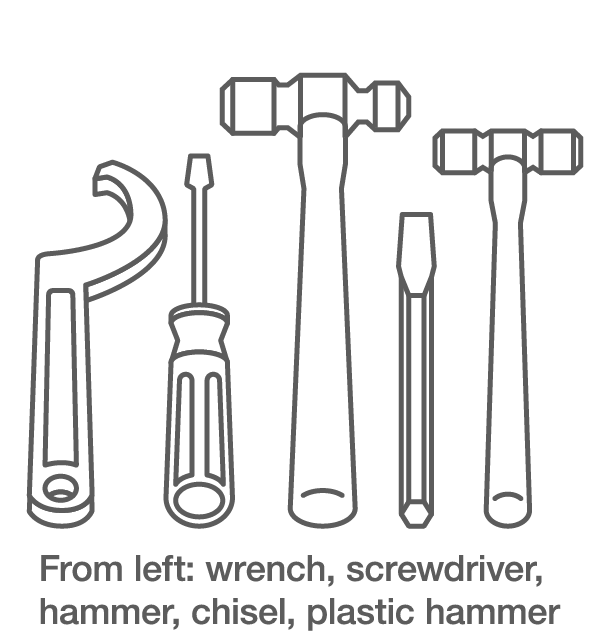

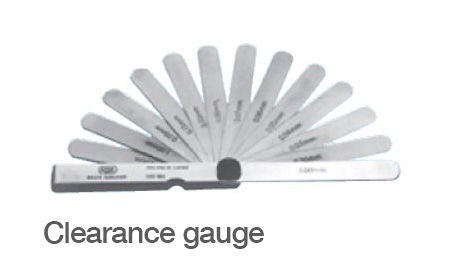

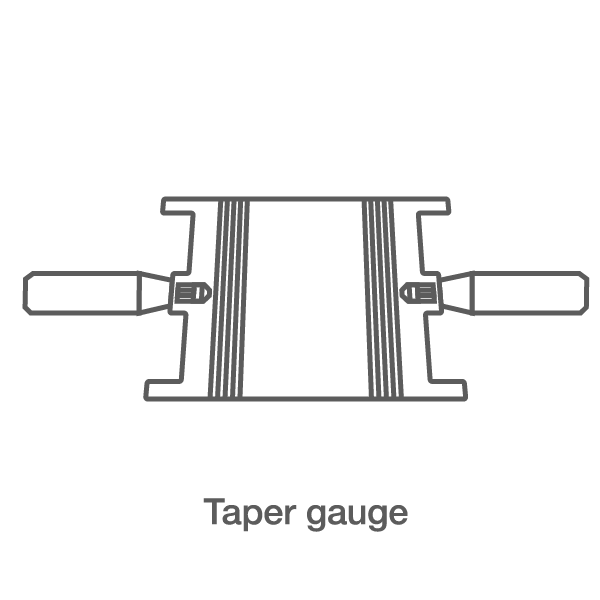

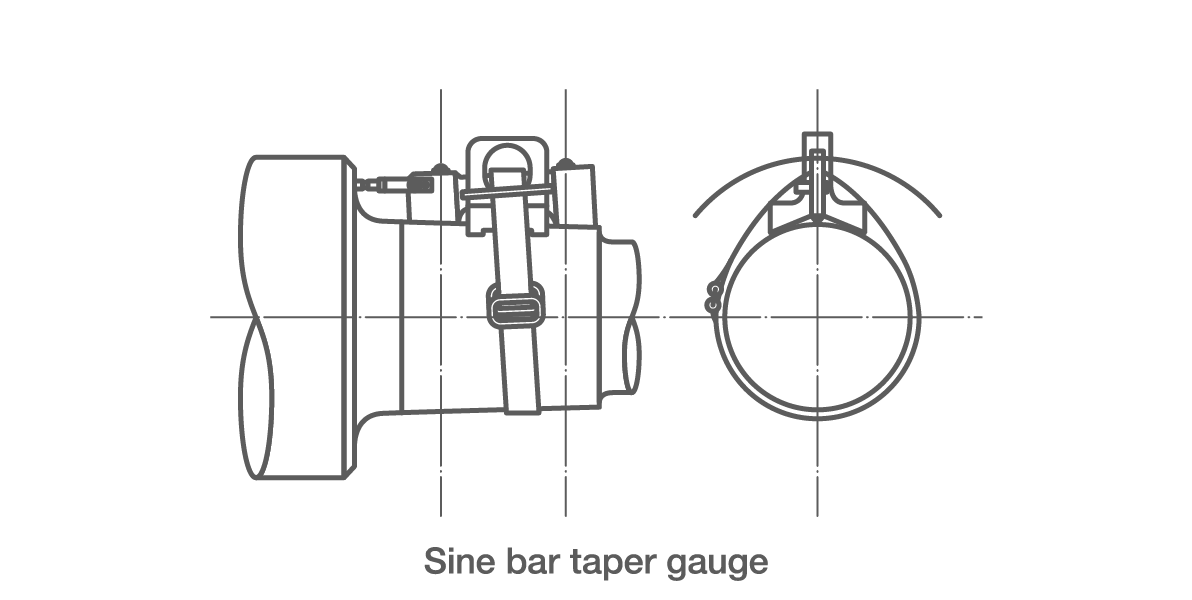

Jigs and Tools for Mounting

Measurement Equipment for Mounting

Other Bearing Mountings

Mounting Bearings With Tapered Bores

1. Tapered Bore Bearings

The inner rings of bearings with tapered bores can be mounted directly on tapered shafts or on cylindrical shafts with adapters or withdrawal sleeves.

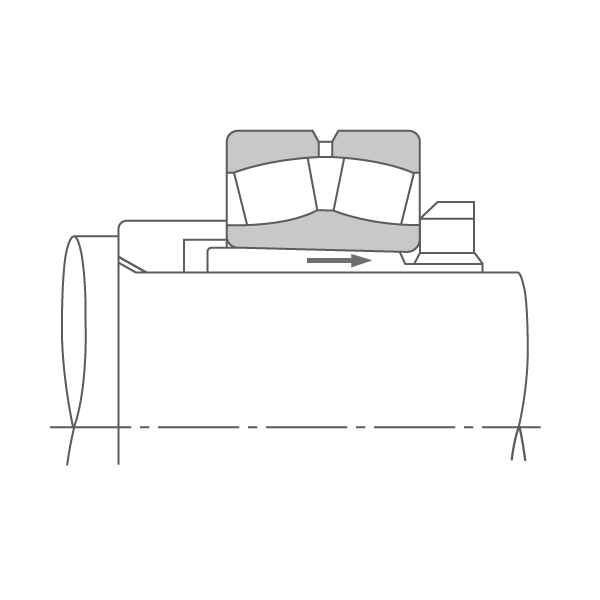

Mounting with adapter

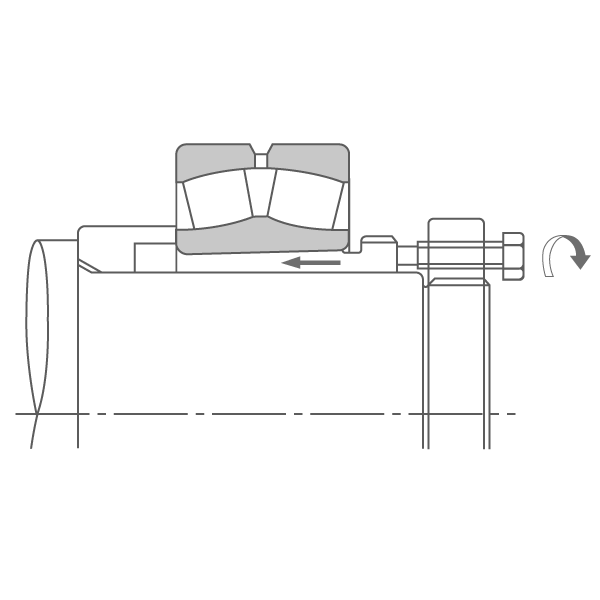

Mounting with a withdrawl sleeve

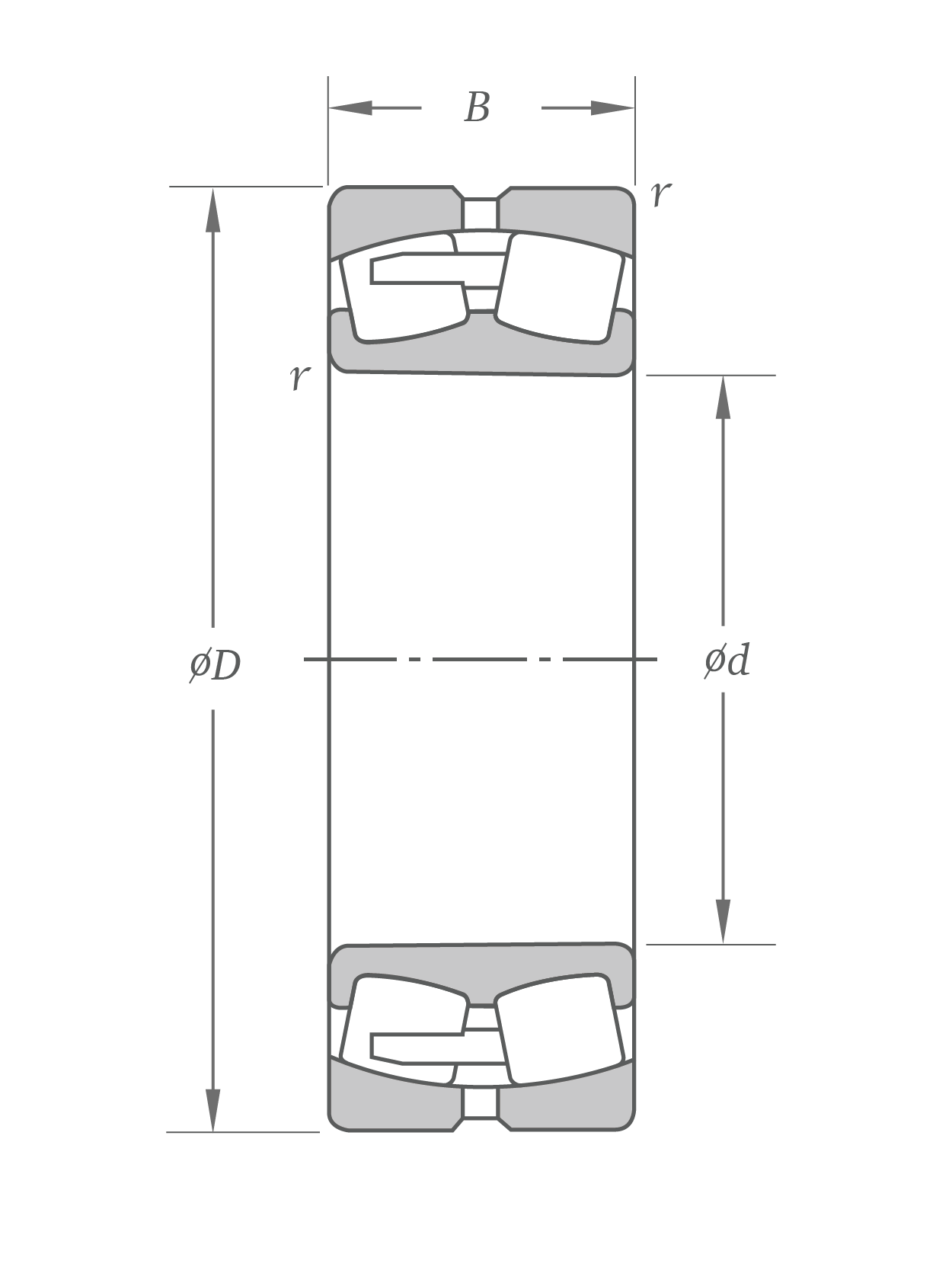

2. Large Spherical Roller Bearings

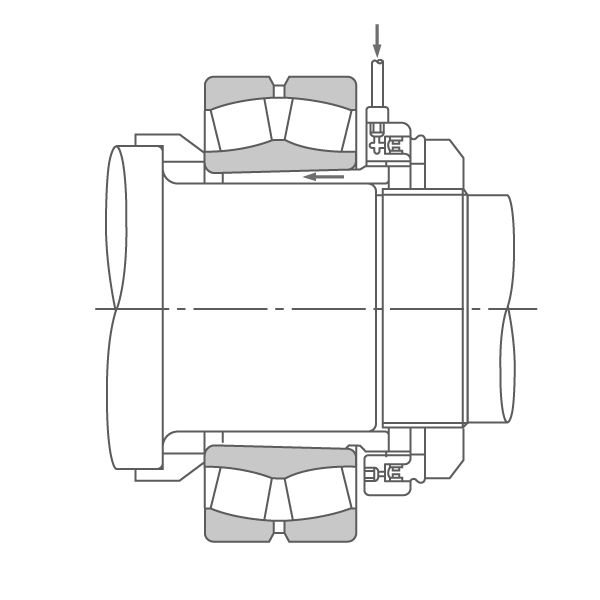

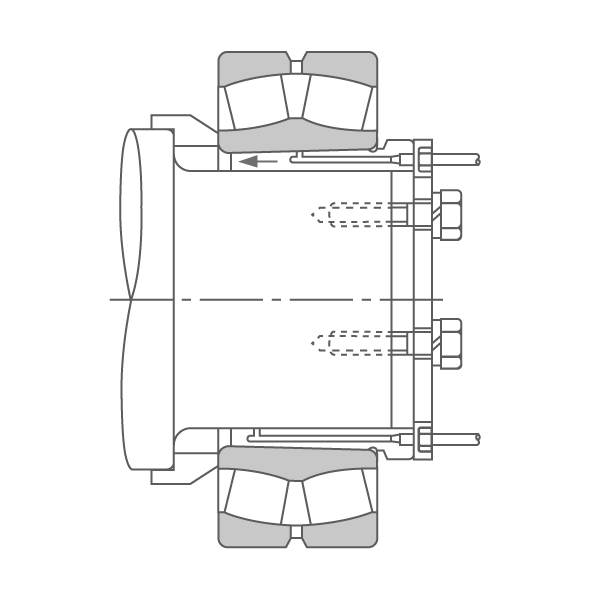

Large spherical roller bearings often use hydraulic pressure to facilitate mounting. Mounting can be performed with a sleeve and hydraulic nut or a method where oil holes drilled in the sleeve are used to feed pressurized oil to the mounting surfaces, allowing the sleeve to be moved into place with mounting bolts.

Mounting with hydraulic nut

Hydraulic mounting with special sleeve

Considerations After Mounting

Take extra care when mounting bearings from different bearing manufacturers.

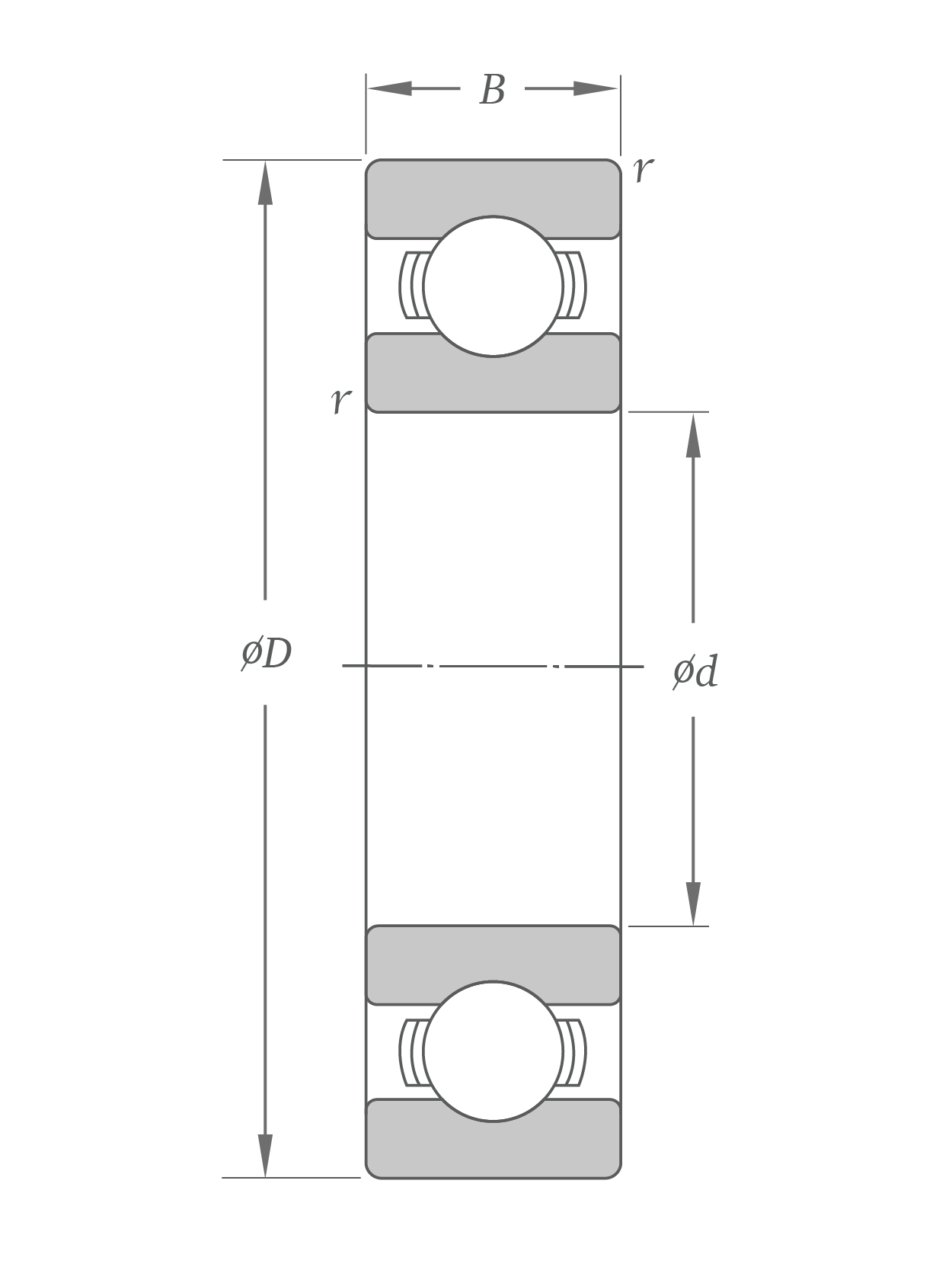

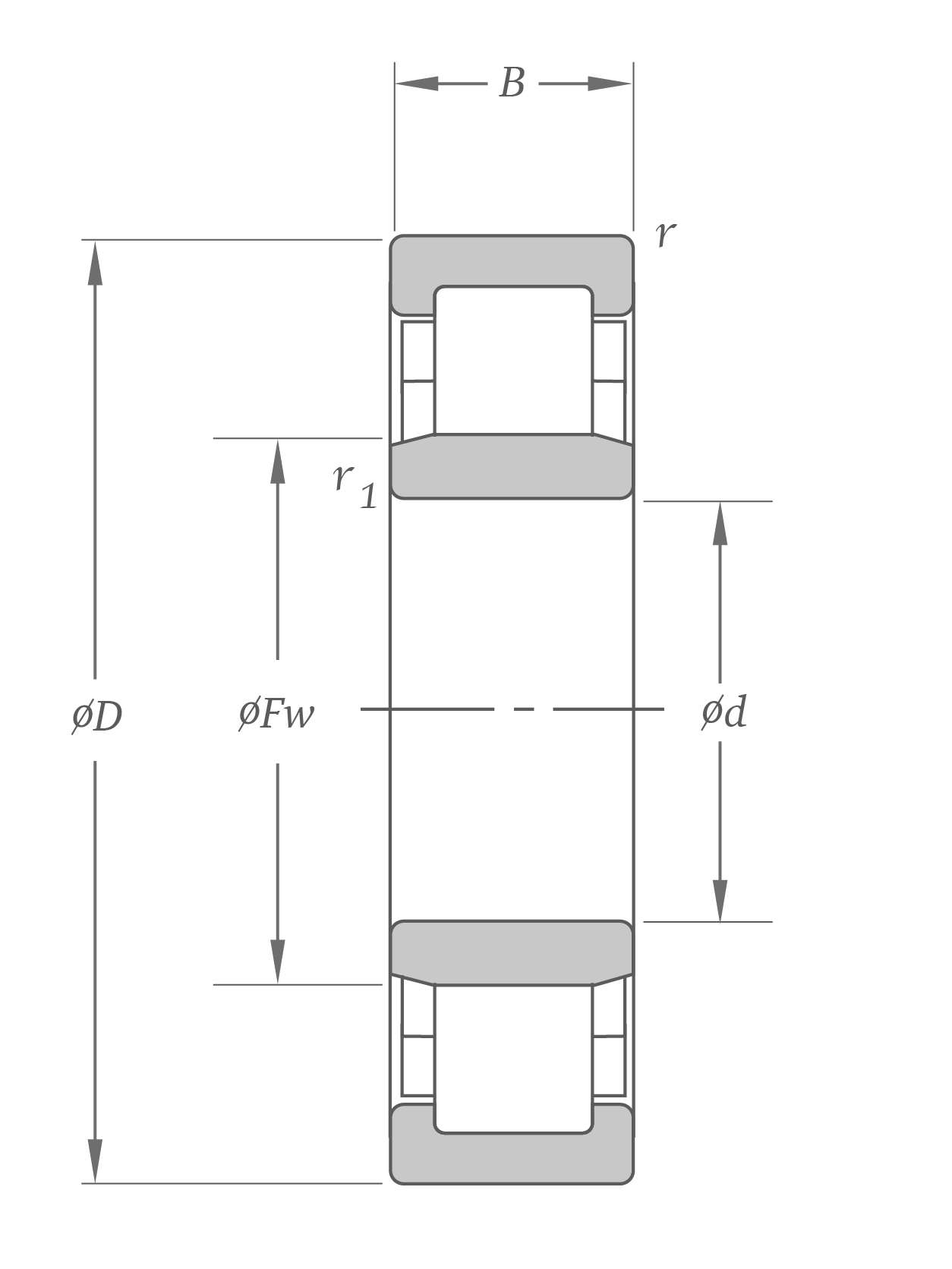

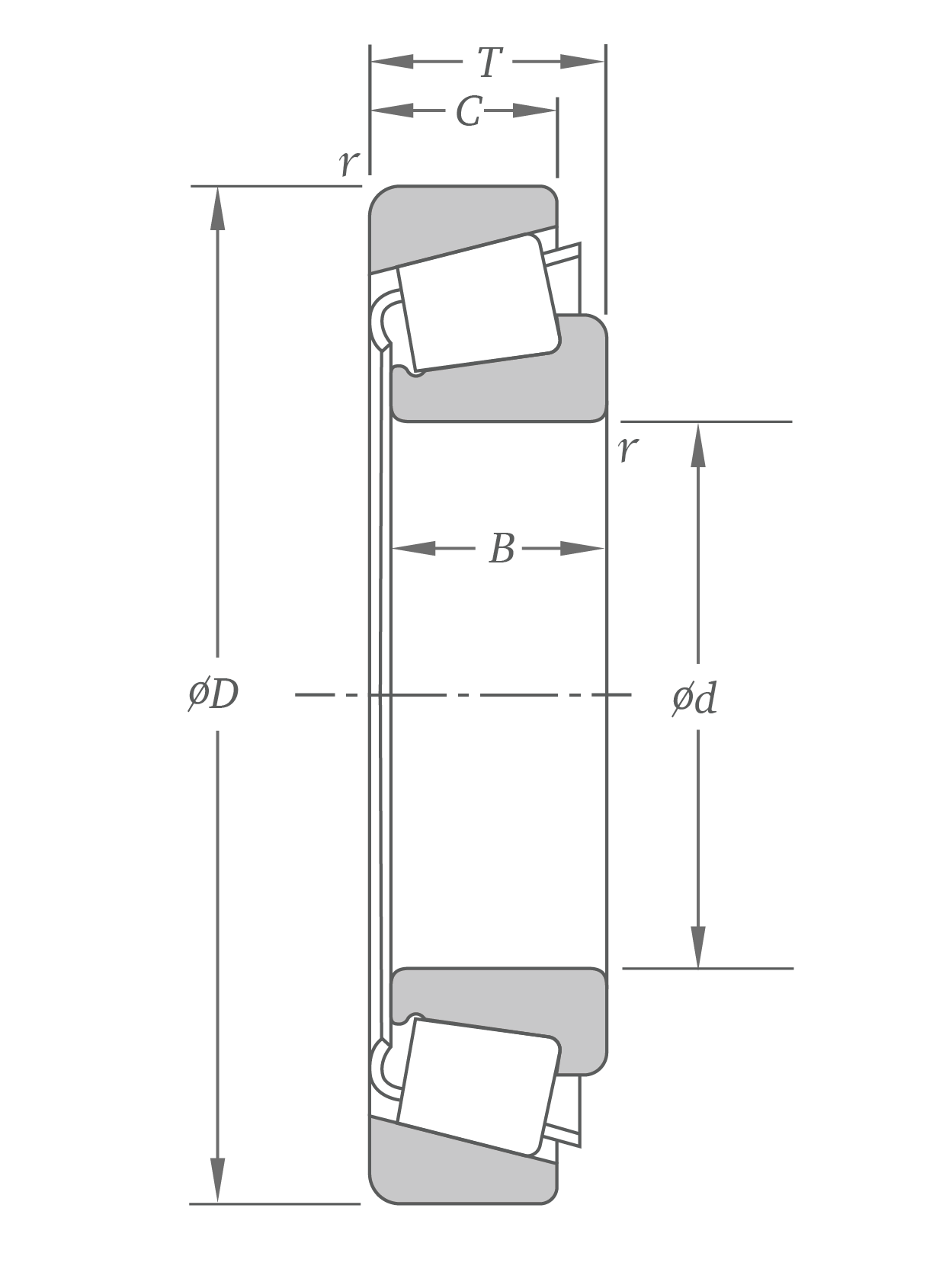

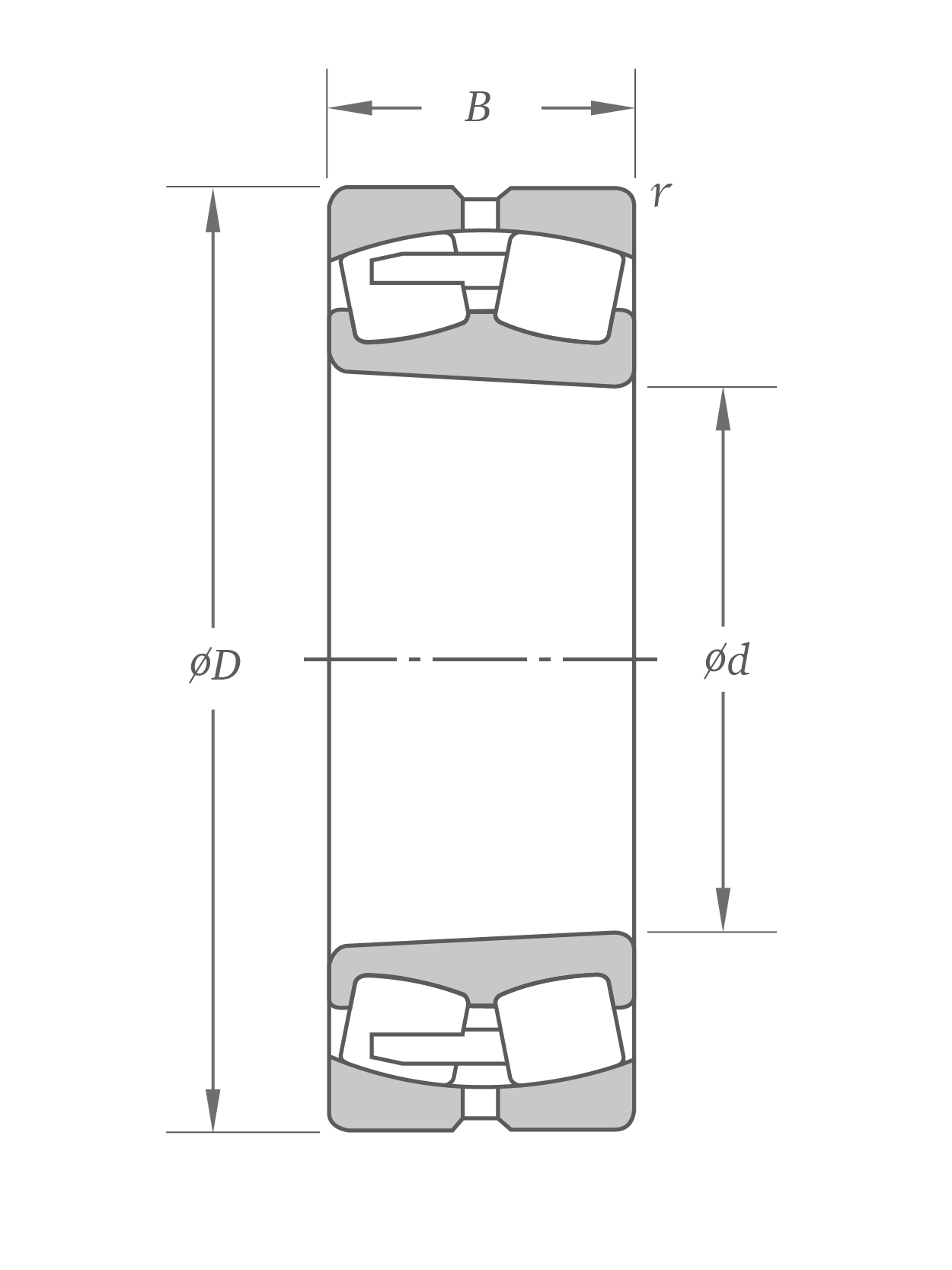

Standard bearings specified by ISO/JIS have standardized dimensions for the bore (d), outer diameter (D), width (B), and so on. However, other specifications (rolling element size, number of rolling elements, etc.) may differ between manufacturers. When using tapered bores or shafts in particular, the residual clearance (clearance after mounting) or the amount of preload may be different, even with the same mounting method. When changing manufacturers, we recommend checking the torque and clearance after assembly.

Deep groove ball bearing (angular contact ball bearing)

Cylindrical roller bearing

Tapered roller bearing

Spherical roller bearing

(cylindrical bore)

Spherical roller bearing

(tapered bore)

Running Test

After bearings are mounted, perform a running test to verify that mounting was completed properly.

If any abnormalities are found during the running test, stop operation immediately and inspect the equipment.

| Equipment Type | Operation Method | Potential Issues |

|---|---|---|

| Small Equipment | Manual operation (rotate by hand) If there are no abnormalities, proceed with powered operation. | ・Sticking (foreign matter, flaws, intentations) ・Uneven rotational torque (improper mounting) ・Excessive torque (insufficient clearance, mounting errors) |

| Powered operation Start at low speed with no load and gradually increase to the specified conditions of rated operation. | ・Abnormal noise ・Change in bearing temperature ・Lubricant leakage, discoloration | |

| Large Equipment | Brief powered operation After starting the machine with no load, immediately turn off the power and allow the machine to coast to a stop. If there are no abnormalities, start normal powered operation. | ・Vibration, Sound, etc. |

| Powered operation Follow the same procedure as for small equipment | (See above.) |

Maintenance and Inspection

Maintenance and inspections help to keep bearings in good condition, ensuring they provide excellent performance for as long as possible.

- Failure prevention

- Improved operational reliability

- Improved productivity

- Improved economy

Predictive monitoring for signs of bearing failure during operation is critical to maintain uptime and keep machines running smoothly.