9.1—Grease Lubrication

Grease lubrication is the most common form of lubrication. Compared to oil, grease helps maintain clean surroundings with less scatter/drips and offers cost advantages with simpler seal structures and longer replacement cycles.

Why Use Grease?

Benefits

Unlike lubricating oil, grease does not require complex equipment (pumps, coolers, etc.). Grease can also be used in small quantities, making it suitable for a wide range of applications. Put simply:

- Grease is easy to use and inexpensive.

- Grease has a proven track record; lubricating grease is used in 80% of rolling bearings.

Deep groove ball bearing filled with grease

Composition

Lubricating grease is made up of a base oil, thickener, and additives. The thickener is dispersed in the oil to make the grease semi-solid, while additives provide other beneficial characteristics.

- Base oil (70-95%)

The base oil is responsible for lubrication. Mineral oil is widely used in general-purpose grease, while synthetic oil is used for high/low-temperature performance and long life. - Additives (several %)

Additives help the base oil work. These include antioxidants, anti-wear agents, extreme-pressure additives, and rust preventives. - Thickener (about 5-30%)

Thickeners maintain the base oil and give the grease its semi-solid properties.

Grease Fill (Grease Quantity)

The appropriate amount of grease to fill in a housing depends on many factors including the bearing’s rotational speed, the housing structure, available internal space, the specific grease brand, the operating environment, and more.

As a general guideline:

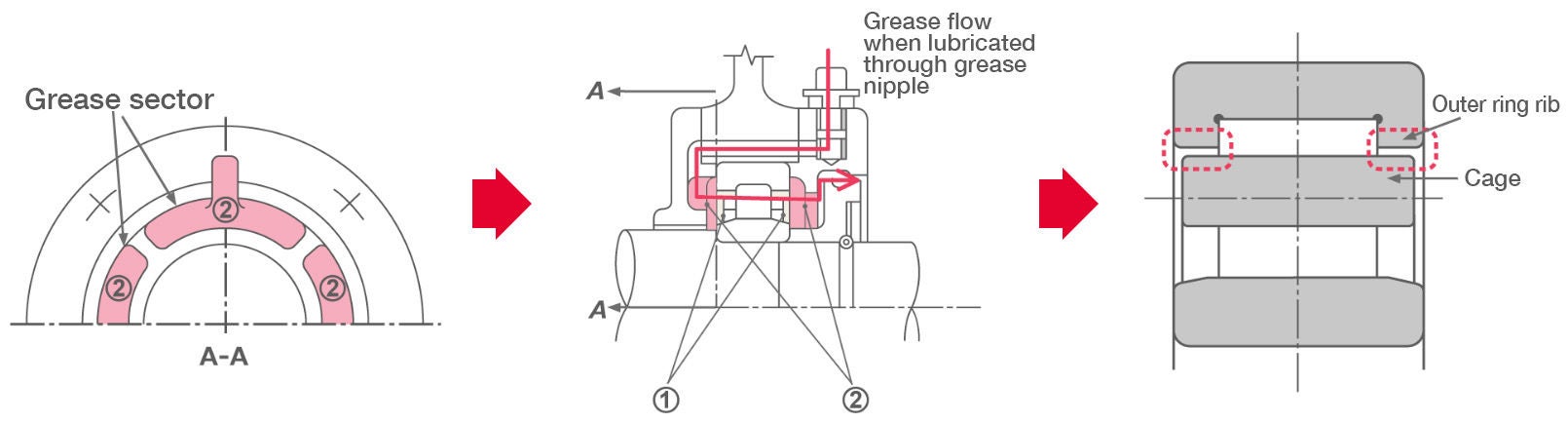

First, fill the bearing interior (the shaded areas below) with sufficient grease.

Apply grease to the outer ring rib bore surface and cage guide surface (cage outside surface). These areas are indicated below by a dotted red outline.

Next, fill the free internal space of the housing (the area excluding the shaft and bearings) to a specified amount depending on the rotational speed:

・Fill 1/2 to 2/3 of the free internal space with grease when the speed is 50% of the limiting speed or less.

・Fill 1/3 to 1/2 of the free internal space with grease when the speed is 50% of the limiting speed or more.

Note that operating conditions may require frequent replenishment or replacement. In such cases, a grease reservoir (grease sector) may be installed on the supply side as shown.

Grease fill

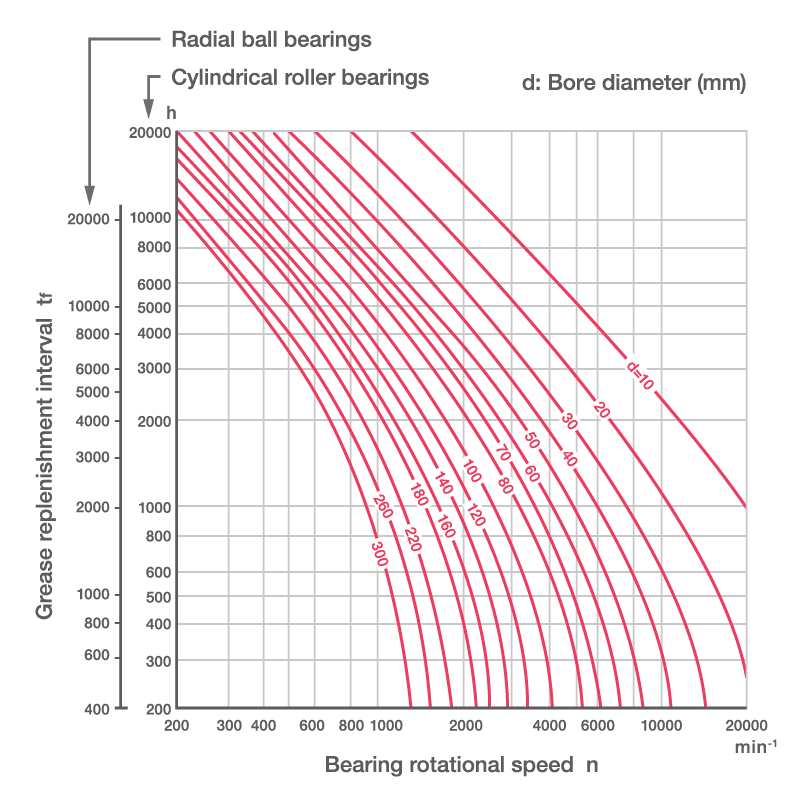

Grease Replenishment Intervals (Radial Ball Bearings and Cylindrical Roller Bearings)

Because grease deteriorates over time and loses its lubricating properties, even high-quality grease must be periodically replenished.

- If the bearing temperature exceeds 70°C, reduce the grease replenishment interval by half for every 15°C increase (no adjustments are required for temperatures under 70°C).

- Adjust replenishment intervals for load by the factors shown in the table below.

| P/C | ≦ 0.06 | 0.1 | 0.13 | 0.16 |

|---|---|---|---|---|

| Correction factor | 1.5 | 1 | 0.65 | 0.45 |

Definitions: P: Dynamic equivalent load, C: Basic dynamic load rating

Grease Life of Sealed Deep Groove Ball Bearings

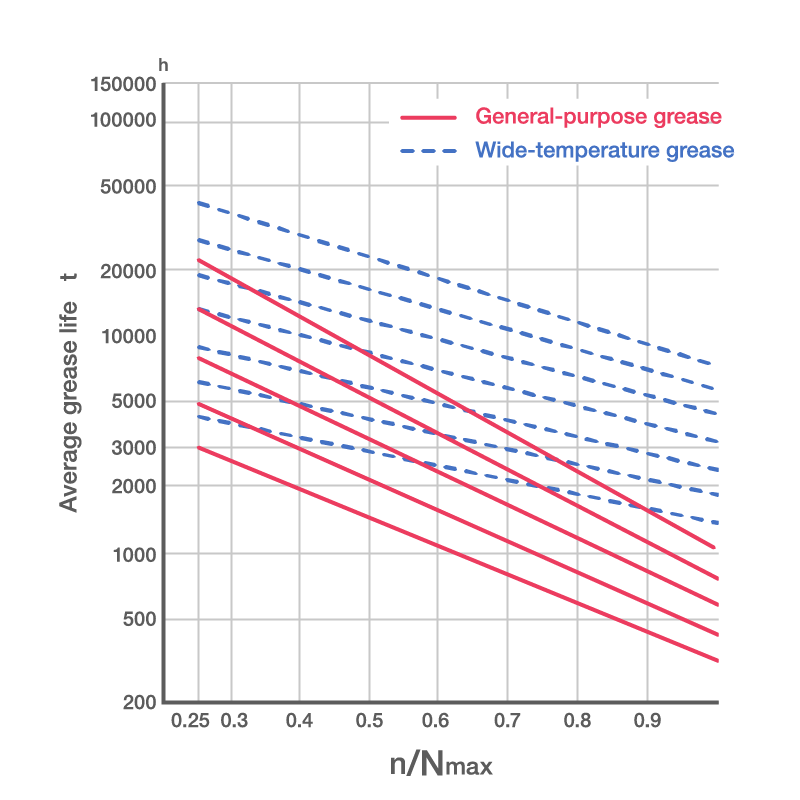

The grease life of a sealed or shielded single-row deep groove ball bearing can be estimated using the equations listed below depending on whether general-purpose grease or wide-temperature (high-temperature) grease is used.

Calculating Grease Life

- Definitions

t: Average grease life (h)

n: Bearing rotational speed (min-1)

Nmax: Limiting speed with grease lubrication (min-1)

(Catalog values with non-contact seals)

T: Bearing operating temperature (°C)

P: Bearing load (N)

C: Basic dynamic load rating (N) - Applicable ranges

When T < 70 °C, make T = 70 °C.

For general-purpose grease: 70 ≤ T ≤ 110 °C (Mineral oil-based grease is used between -10 to 110 °C)

For wide-temperature grease: 70 ≦ T ≦ 130 °C (Synthetic oil-based grease is used between -40 to 130 °C) - Conditions

0.25 ≦ n / Nmax ≦ 1 (n / Nmax= 0.25 when n / Nmax < 0.25)

P/C ≦ 0.1

General-purpose grease

Wide-temperature grease