6—Bearing Tolerances

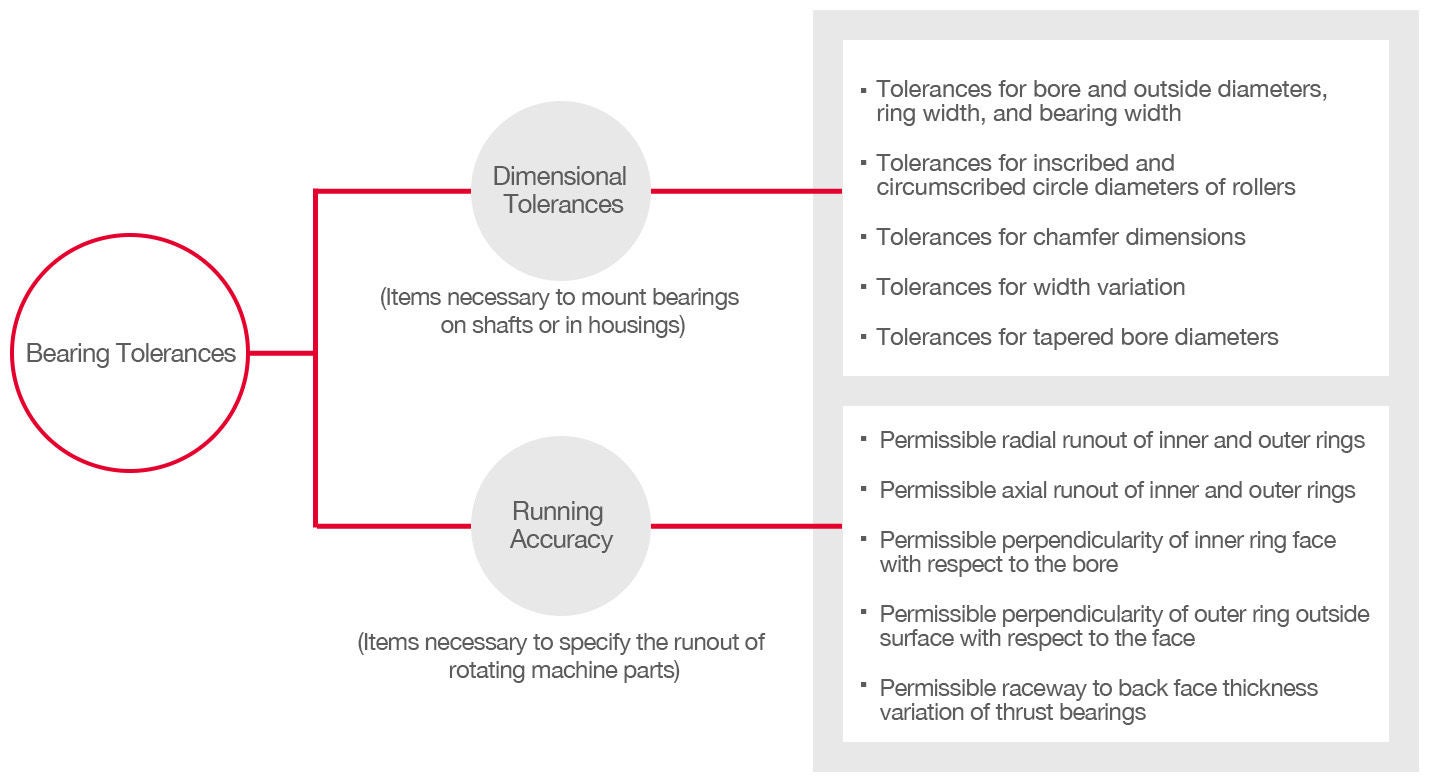

Bearing tolerances indicate acceptable values for dimensions and running accuracy for a given tolerance class. Tolerances are standardized internationally by organizations including ISO, JIS, DIN, ANSI, and ABMA.

Bearing Tolerances

Tolerances and permissible values for boundary dimensions and running accuracy are specified in JIS B 1514, ISO 492 (radial bearings), and ISO 199 (thrust bearings).

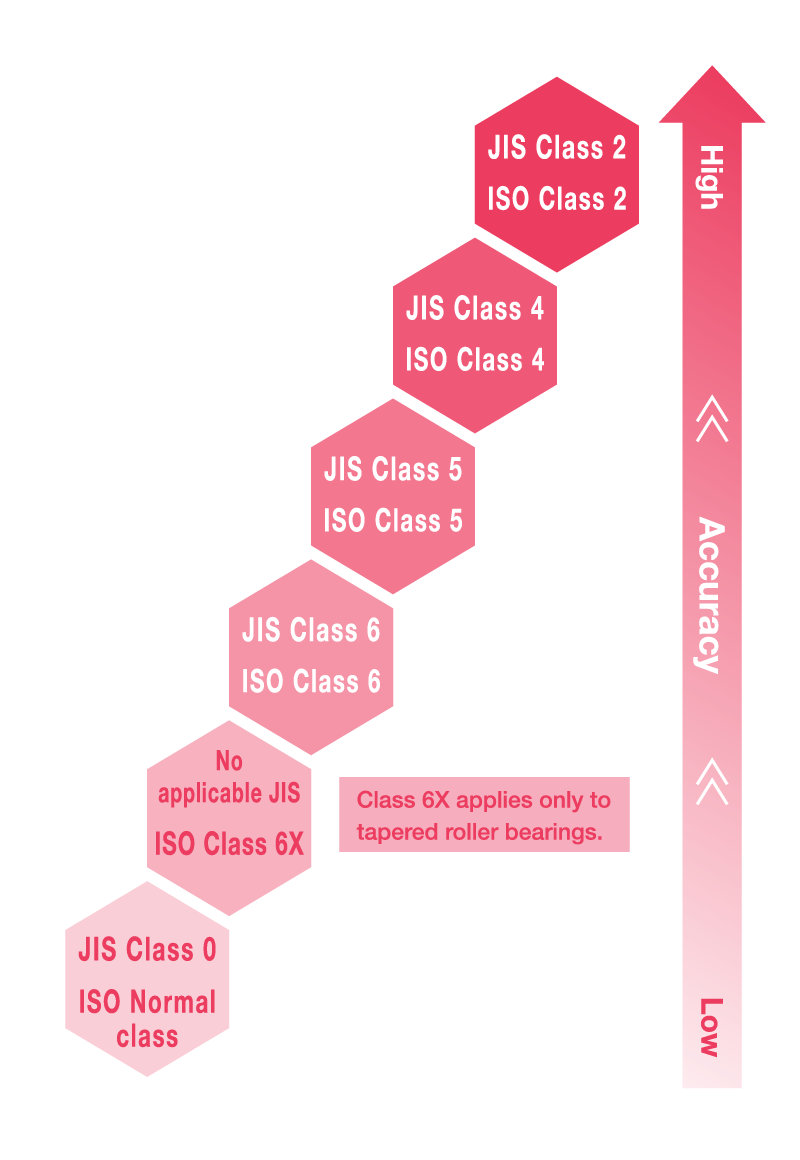

Bearing Tolerance Classes

For most general applications, JIS 0 (ISO Normal class) is sufficient.

Class 5 or higher products are used in machine tool spindles, specialized instruments, and other precision equipment, as well as in high-speed applications such as aircraft.