Supply Chain Management

NSK’s Approach

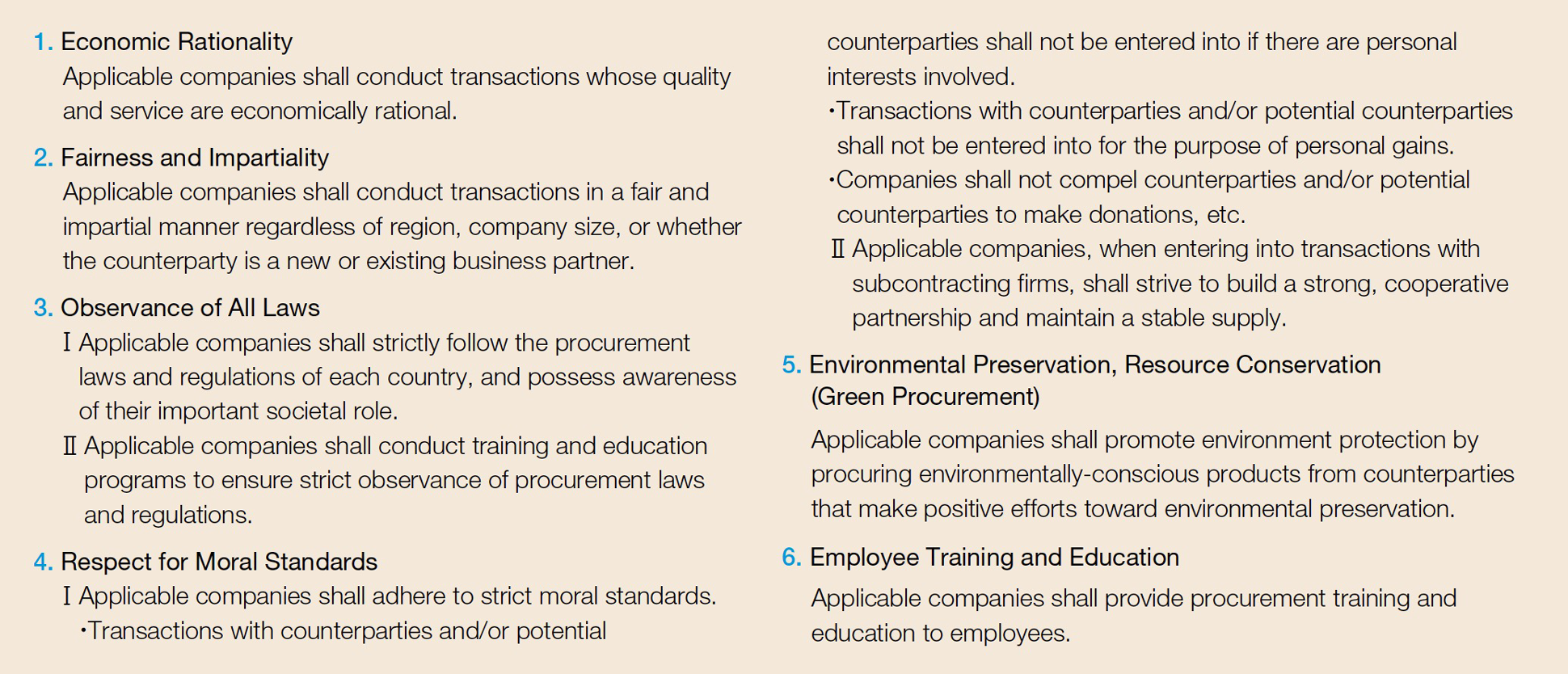

NSK considers suppliers to be indispensable business partners for NSK and aims for mutual development while building relationships of trust. Based on our basic philosophy of conducting fair and impartial procurement activities that are considerate of impacts on both society and the environment, we are engaged in efforts throughout our entire supply chain to help create a sustainable society.

◆Mission of NSK’s Procurement Division

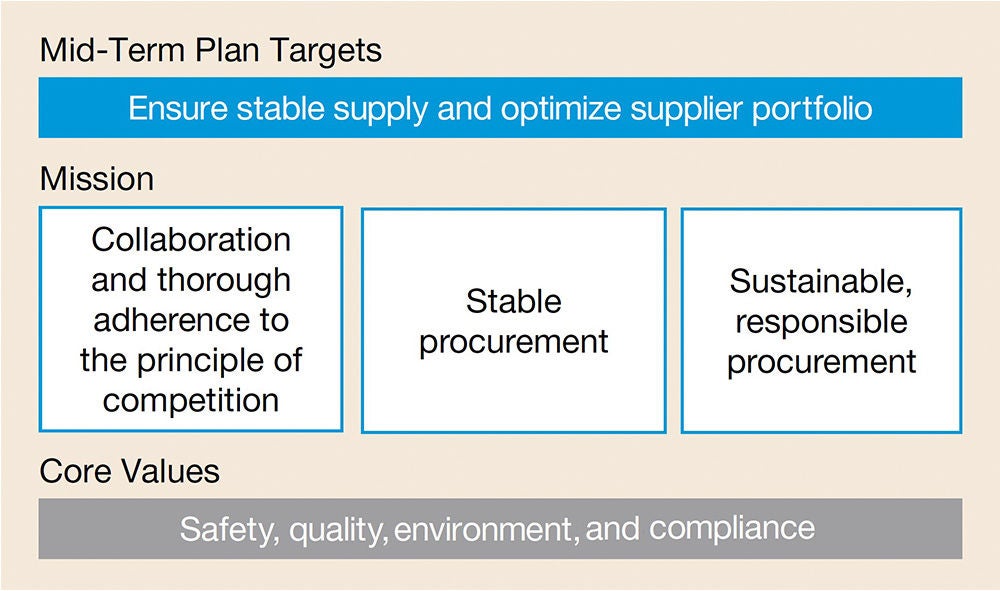

NSK’s procurement division strives to improve earnings and cost competitiveness by ensuring stable procurement and optimizing quality, cost, and delivery time through fair, transparent transactions with suppliers. In our relationships with suppliers, we practice sustainable, responsible procurement by ensuring compliance and focusing on CSR procurement. We also share our Green Procurement Standards and Supplier CSR Guidelines with suppliers in order to foster CSR activities throughout the supply chain.

Mid-Term Management Plan 2026: Procurement Division Headquarters

◆Policy

NSK Group Basic Policy for Procurement

◆NSK Supplier CSR Guidelines

NSK distributes the NSK Supplier CSR Guidelines to approximately 1,700 main global suppliers, requesting compliance initiatives such as adherence to competition and antibribery laws, human rights and labor initiatives such as the prohibition of child labor and forced labor and occupational health and safety, environmental initiatives such as reductions in CO2 emissions, and community initiatives such as avoiding the use of conflict minerals.

NSK Supplier CSR Guidelines Key Items

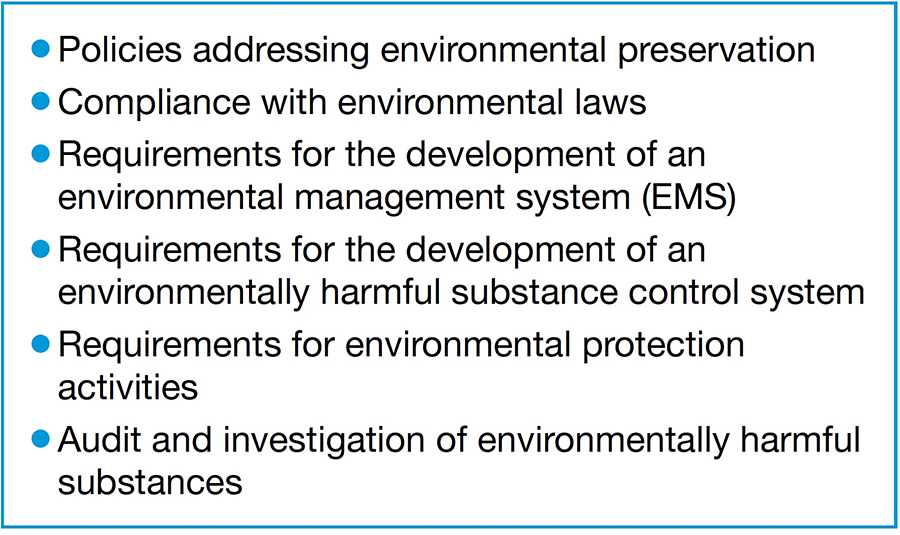

◆NSK Group Green Procurement Standards

The NSK Group has established standards for green procurement throughout the supply chain, starting at the beginning with parts and materials, and works together with suppliers on this issue. The standards address efforts to fight climate change, promote resource conservation and recycling, manage environmentally harmful substances, and other important matters.

NSK Group Green Procurement Standards Key Items

System

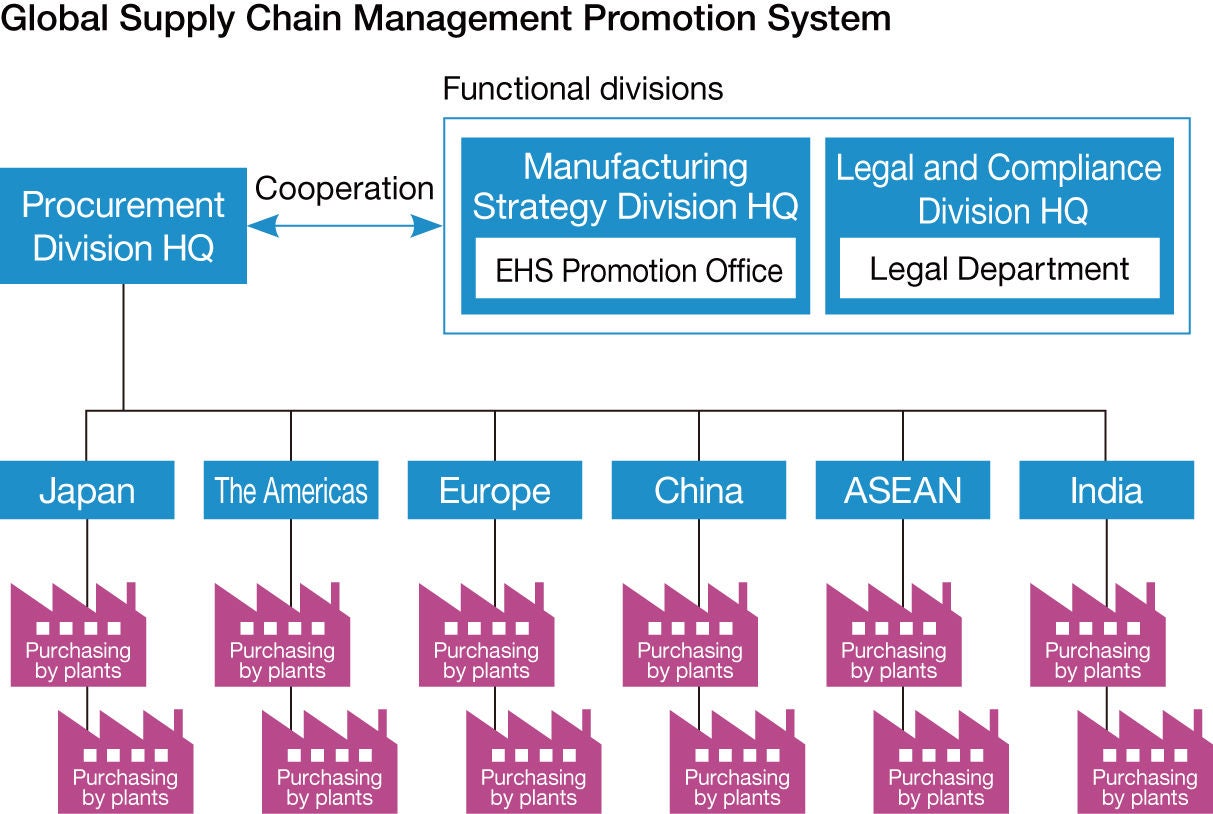

◆Global Supply Chain Management Promotion System

The Procurement Division Headquarters is tasked with ensuring that the NSK Group fulfills its social responsibility throughout the entire supply chain. Directed by a senior vice president, it plays a central role in building systems to promote supply chain management, working in collaboration with relevant functional divisions, procurement and administrative divisions within the NSK Group. Procurement policies and progress on CSR procurement and other related measures are reviewed at the biannual Global Procurement Conference, which brings together those responsible for procurement from each region of the world.

Targets and Performance

◆Mid-Term Management Plan 2026 (MTP2026) Targets, with Targets and Performance for Each Fiscal Year

| Policy | Rebuild the foundation for procurement reform using a global overall optimization perspective instead of pursuing only individual optimization | ||

|---|---|---|---|

| MTP2026 | Targets |

|

|

| FY2023 | Targets |

|

|

| Performance |

|

| |

| FY2024 | Targets |

|

|

Initiatives

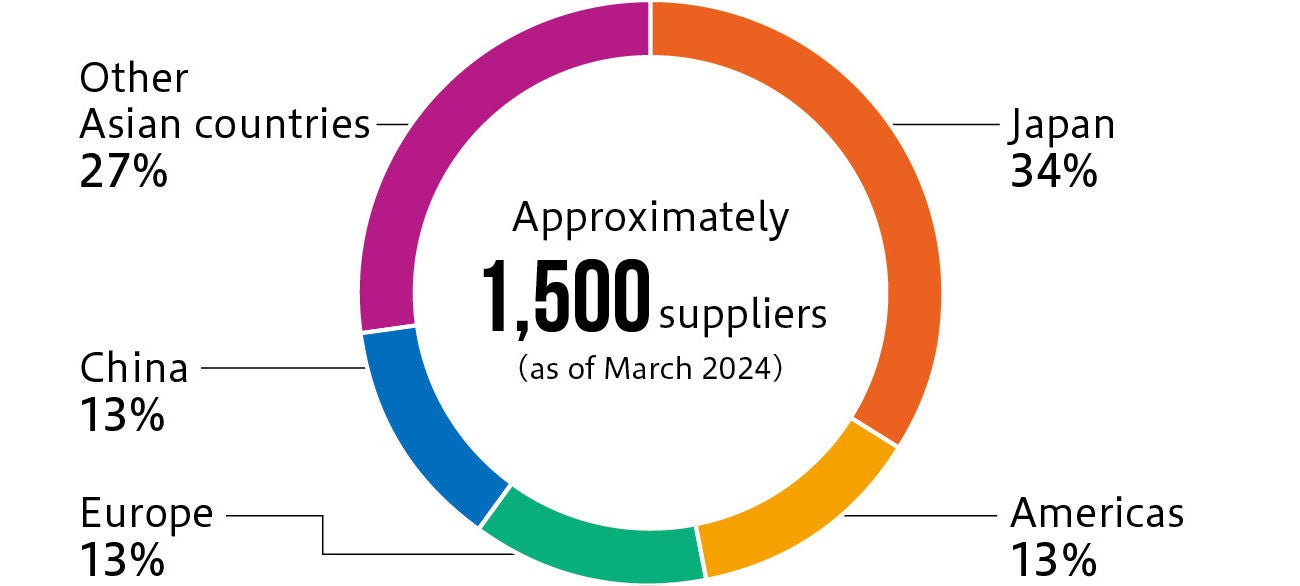

◆Regional Distribution of the NSK Group’s Supply Chain

The NSK Group collaborates with approximately 1,500 direct material suppliers globally (adjusted for overlaps between regions.)

Ratio of NSK Group Suppliers by Region (Number of Suppliers)

◆Stable Procurement Based on Relationships of Trust

Sharing NSK’s Value Creation with Suppliers

Every year, the NSK Group holds procurement policy briefings to communicate to major suppliers on information about heightened social demands, such as human rights, labor practices, and climate change countermeasures. We also explain initiatives that NSK expects suppliers to take, such as improving occupational safety and reducing CO2 emissions, while calling for coordinated efforts across the entire supply chain. In May 2024, 87 companies participated in procurement policy briefings.

In FY2023, we distributed a video about the NSK Human Rights Policy and related initiatives to some suppliers, and collected their opinions, impressions, and other feedback.

Procurement policy briefing

Promoting Fair Trade

In 2017, the NSK Group created an internal manual to address various fair trade trends in government and industry, such as laws and regulations like Japan’s Act against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors, and industry agreements like the Voluntary Action Plan of the Japan Automobile Manufacturers Association, Inc. and Japan Auto Parts Industries Association. The manual is designed for employees involved in procurement, and it covers key issues and warns against specific types of conduct that are likely to be viewed with suspicion. We disseminated the manual and continue to work hard to promote fair trade.

Compliance Hotline

The NSK Group has established the compliance hotline (whistleblowing system) to enable anyone to anonymously convey their criticisms, opinions, and concerns. This helps to ensure any issues will be identified at an early stage so corrective measures can be taken. In Japan, for example, the hotline has two points of contact: one is the Head of the Legal and Compliance Division Headquarters and the other is an outside attorney. We are careful to ensure that not only internal whistleblowers but also suppliers can use the hotline safely and securely and face no repercussions as a result. We have distributed leaflets to make the compliance hotline more widely known.

◆Identifying and Managing Risks in the Supply Chain

Supplier Risk Management

The NSK Group confirms that all suppliers understand the NSK Supplier CSR Guidelines and NSK Group Green Procurement Standards and agree to adhere to the relevant items therein. We have also incorporated clauses on environmental, social, and governance (ESG) performance into basic transaction agreements to further strengthen risk management. We determine the risk that each supplier in NSK’s supply chain presents by taking into account the procurement cost and volume, the importance of the procured parts, the availability of replacements, the risk of the presence of environmentally harmful substances and conflict minerals, and the risk of damage from earthquakes, wind or flood.

Suppliers estimated to present a high level of risk are placed under critical control, and we assess supplier risk by checking their financial condition, requiring them to conduct CSR self-assessments, and other methods. The necessary measures to reduce risk are then implemented in close collaboration between those suppliers and the relevant departments at NSK, such as design and production. We also conduct a careful study of risk before beginning to do business with any new supplier. We confirm their management structure, check for legal violations including violations of environmental and labor laws, and verify practices related to quality control and environmental management, among other things.

・Management / financial soundness

・Initiatives for QCD (quality, cost and delivery [stable supply capacity])

・Technological and development capabilities

・CSR initiatives (initiatives for environment, occupational safety, disaster prevention, conflict minerals, etc.)

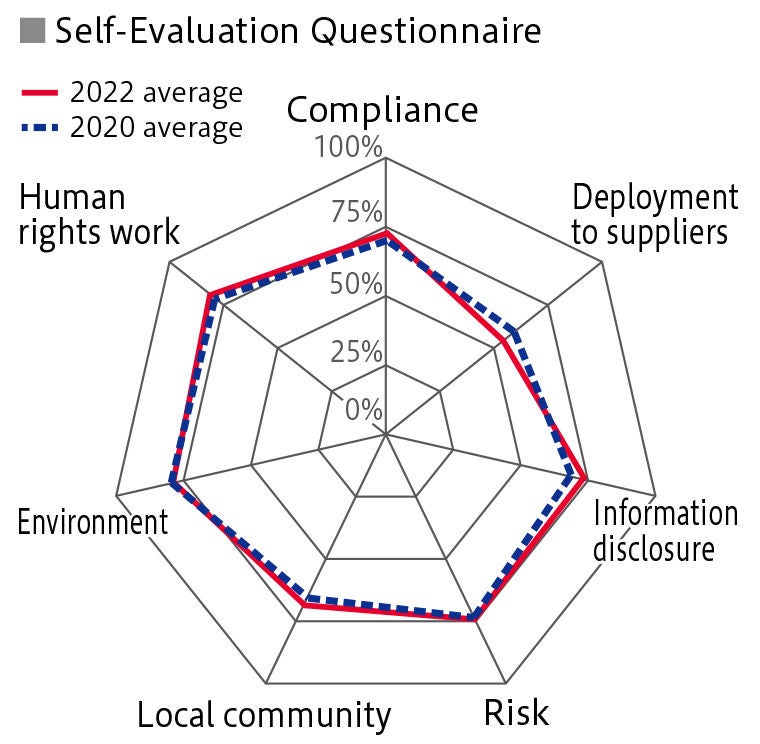

Supplier CSR Self-Assessment

The NSK Group asks its suppliers to perform CSR self-assessments and monitors the condition of their operations (every two years). We then report the results of our evaluation of their activities back to the suppliers. In Japan, we conducted self-assessments in FY2022 and requested responses from approximately 500 suppliers, receiving responses from about 90% of them. We provided feedback on the survey results to each company and requested that they take measures to address identified issues, such as strengthening preventive measures against occupational accidents and improving the level of green procurement. We also regularly conduct monitoring through self-assessments at each site for suppliers outside Japan. Requirements regarding human rights and the environment are becoming stricter in each region, and we will work with our suppliers to improve the level of compliance.

◆Enhancement of Supply Chain BCP Effectiveness (Japan)

The NSK Group has built a system for quickly identifying the scale of damage and problems at suppliers in the event of a disaster. The system also facilitates a precisely targeted response with the cooperation of suppliers. Drills are conducted regularly to ensure sites properly utilize the Supplier Safety Confirmation System, which is used for emergency contact. We have also asked major suppliers to create their own Business Continuity Plans (BCP) and verified their progress in order to strengthen risk management throughout the supply chain.