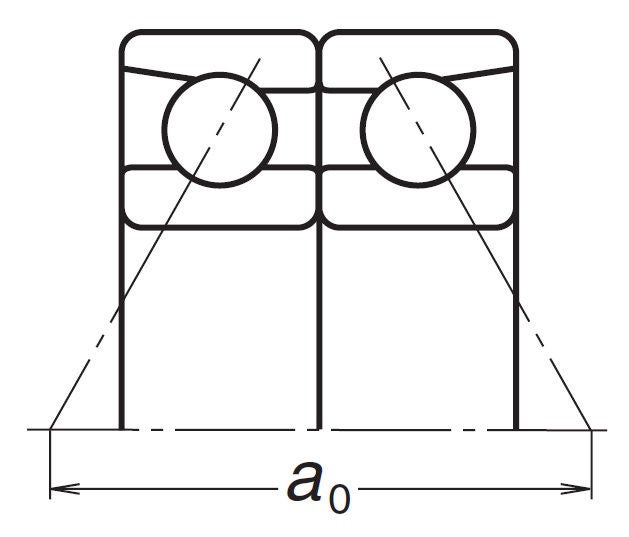

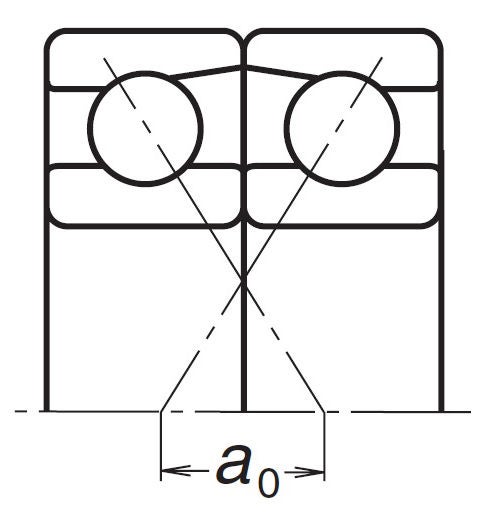

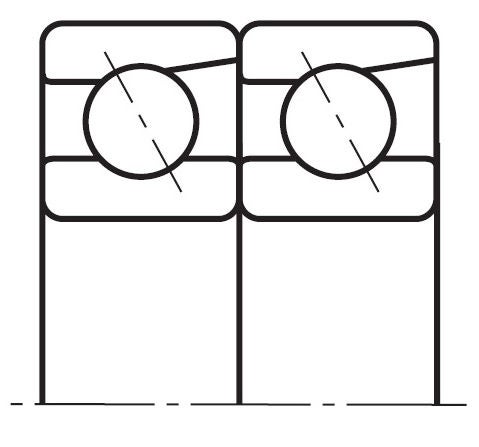

The structure of angular contact ball bearings produces an axial component when a radial or combined load is applied; therefore, two opposed bearings or a multi-bearing arrangement are used.

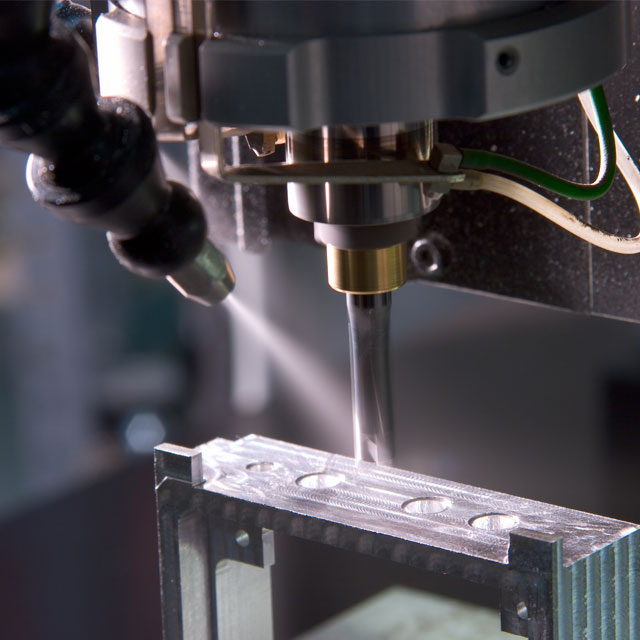

A preload is often used to increase the rigidity of single-row angular contact ball bearings, particularly in the main spindles of machine tools where high running accuracy is crucial.

Bearings with a contact angle of 30° (A) or 40° (B) typically use pressed steel, molded resin, or machined brass cages, though machined synthetic resin or specialized polyamide resin cages are used for certain applications.

Reference 1 Cages for Angular Contact Ball Bearings by Series

| Series | Pressed Steel Cages | Machined Brass Cages |

|---|

| 79A5,C | - | 7900-7940 |

| 70A | 7000-7018 | 7019-7040 |

| 70C | - | 7000-7022 |

| 72A,B | 7200-7222 | 7224-7240 |

| 72C | - | 7200-7240 |

| 73A,B | 7300-7320 | 7321-7340 |

Features

- Support both radial and axial loads

Single-row ACBBs can take radial loads and axial loads in one direction with typical contact angles of 30° or 40°. - A variety of contact angles

Larger contact angles offer greater capacity for axial loads, while smaller contact angles are better for high-speed rotation. - Two opposed bearings are used to adjust internal clearance. Pressed steel cages are common, though polyamide resin cages are typically used for high-precision bearings with contact angles under 30°.

Applications

- High rigidity

Ideal for applications requiring bearing rigidity. - Pumps, compressors, screw chillers, elevator hoists