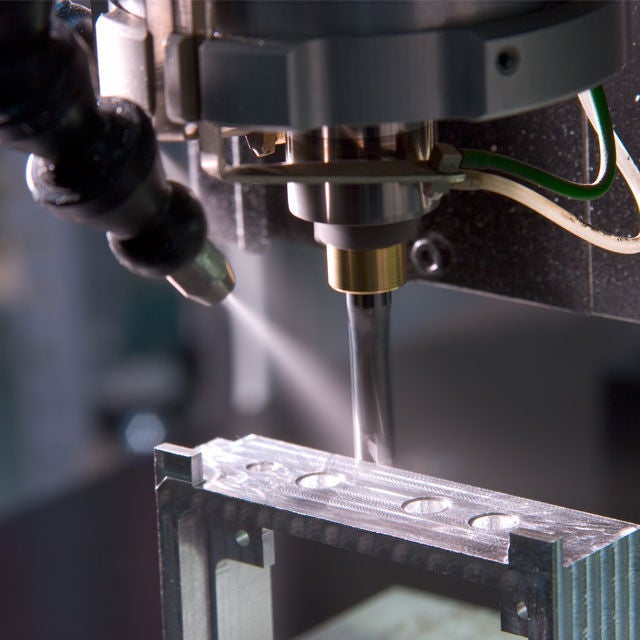

Machine Tools

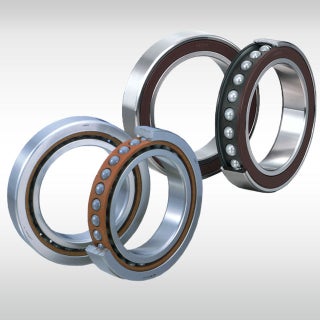

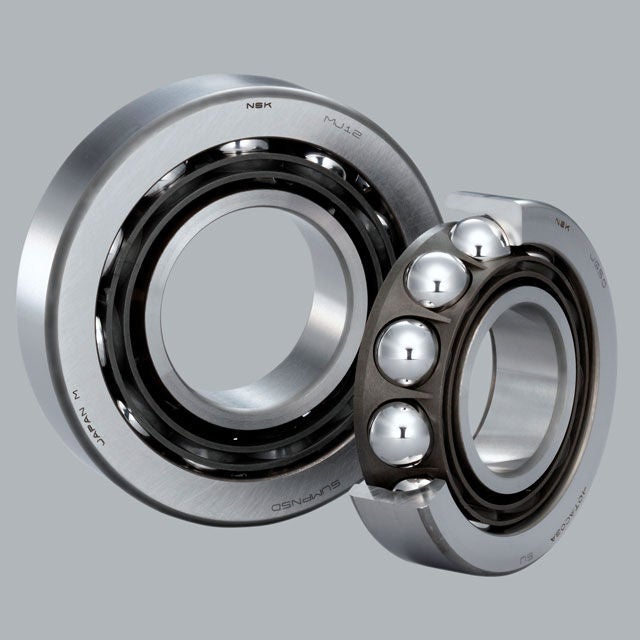

NSK is the only manufacturer to offer a complete development and supply service for the essential parts required for machine tools. NSK enjoys unshakeable global product strength for its bearings used in machine tools. These include:

- high precision bearings supplied from Japan and the United Kingdom

- spindles that offer easily the fastest spin speed capability available, and are of the highest standard in their class worldwide

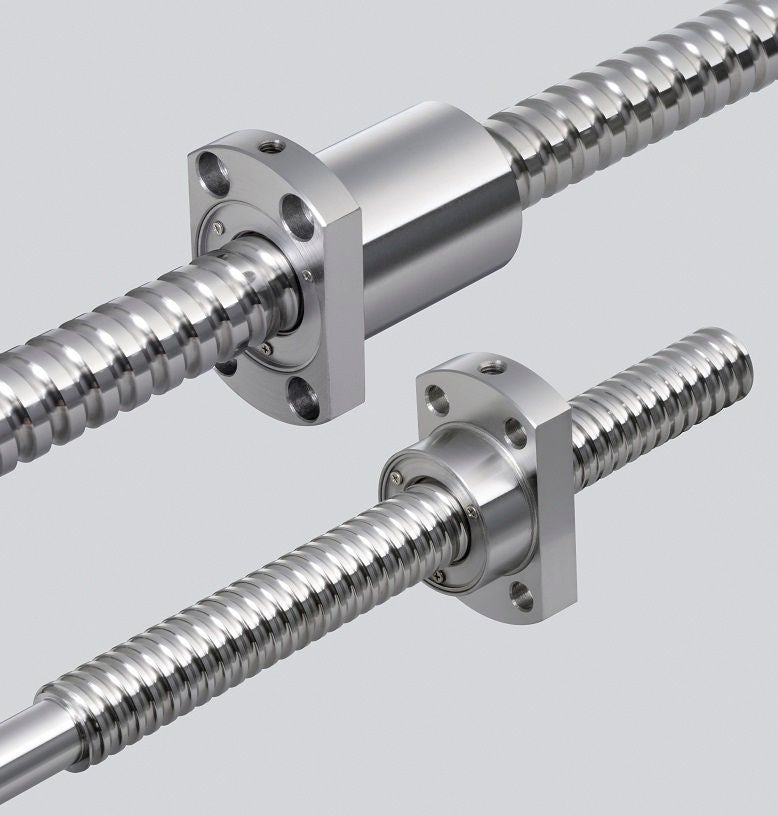

- ball screws that have achieved top global brand status as a result of the cutting-edge technologies used

- NSK Linear guides™ that are manufactured using production technologies guaranteeing high precision and product quality.

NSK possesses analytical technologies closely based on tribology (friction control technologies) which are used to reduce energy losses to the absolute minimum, as well as evaluation technologies to rigorously assess how best to meet customer needs, and lubrication technologies that achieve both reductions in energy losses and increases in capacity.

NSK is also continuing to amass key materials engineering technologies that contribute to longer product life. Further, in response to customer requirements for precision bearings for high functionality and environmental protection, the company is developing environmentally friendly products.

As a comprehensive manufacturer of machinery parts, NSK is able to meet the increasingly sophisticated needs of its clients, and it can assist with both a speedy commencement of operations for machine tools, as well as optimal overall operation.