NSK Ltd.

Corporate Communications Department

NSK to Exhibit at EMO Hannover 2025, a Machine Tool Exhibition in Europe

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) will participate in EMO Hannover 2025, one of the world’s largest machine tool fairs, held at the Hannover Fairgrounds in Germany from September 22 (Mon.) to September 26 (Fri.), 2025.

■ Exhibition Overview

| Exhibition Name | EMO Hannover 2025 |

| Dates | September 22 (Mon.) – September 26 (Fri.), 2025 |

| Venue | Hannover Fairgrounds NSK Booth: Hall 6, Booth No. J17 |

| Official Website | https://emo-hannover.com/ |

■ Main Exhibits and Technology Presentations

1. J-Type ROBUSTDYNA™ Bearings for Machine Tool Spindles

• Optimized bearing internal design, for instance by employing larger diameter balls, increases load capacity by 15% compared to conventional products,*1 supporting heavy-duty cutting.

*1 NSK’s current H-type Robust Series bearings (SUJ2 version)

• Optimized internal specifications deliver high-speed performance equivalent to that of conventional products, enabling use in both low-speed and high-speed applications.

• Optimized internal design and the use of NSK’s proprietary long-life steel NSK improve service life, making it up to six times longer than that of conventional products.

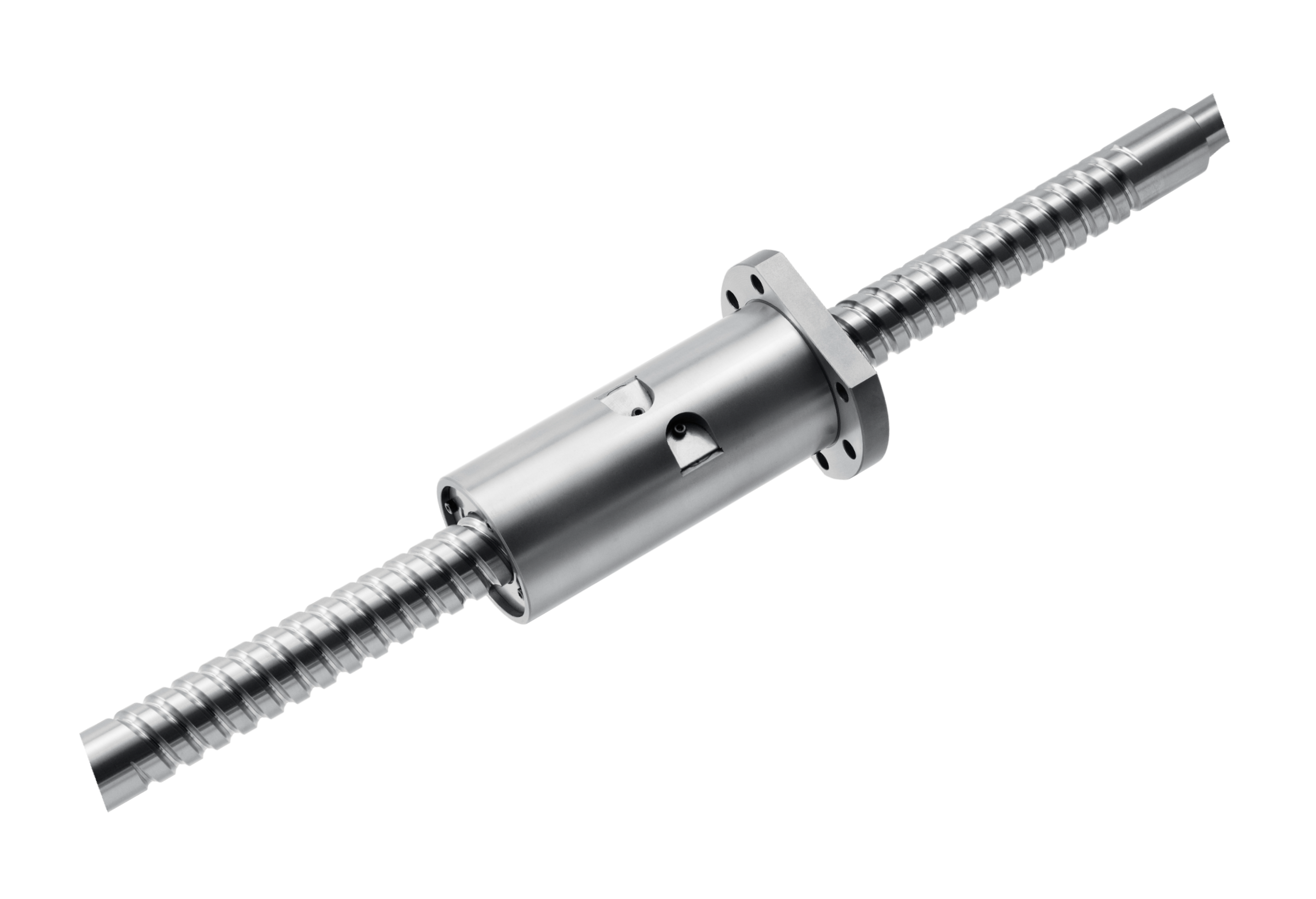

2. Ball Screws for Next-Generation High-Accuracy Machine Tools

• Reduced friction fluctuations when ball screws reverse direction minimizes quadrant glitch motion errors.

• Friction characteristics that are easier to control via NC systems contribute to better quality machined surfaces.

3. MT-Frix™ Low-Friction Ball Screws for Machine Tools (Panel Display)

• A significant reduction in dynamic friction torque and the heat generation of ball screws deliver more sustainable machine tool accuracy and better energy saving.

Related Press Release:

September 17, 2025 – NSK Publishes Industry's First Ball Screw CFP Assessment Report

• Application of NSK’s proprietary TF heat treatment technology delivers over twice the running distance of conventional products.

• High reliability for machine tool applications.

• New random matching option for rails and sliders helps shorten delivery times.

5. Condition Monitoring Solution

• Learn about NSK’s advanced condition monitoring solution integrating AI and diagnostic technologies, which helps optimize maintenance and reduces workload.

• See a live demonstration of the condition monitoring solution designed for linear motion machinery.

About NSK

NSK produced the first bearings in Japan in 1916 and over the past 100 years, it has supported the development of industries worldwide by creating various innovative products and technologies in bearings, automotive parts, and precision machinery. Since the early 1960s, the company has expanded overseas and now has operations in about 30 countries. It ranks third in the world in the field of bearings and leads the world in ball screws, electric power steering, and other products.