NSK Ltd.

Corporate Communications Department

NSK to Exhibit at Automotive Engineering Exposition 2024 Yokohama

● NSK to showcase a wide range of products that contribute to the electrification of “Driving”, “Steering”, and “Braking”, with a view to achieving a carbon-neutral, safe, and comfortable mobility society

● World’s first exhibition of the centrifugal force disconnect module and the ultra-low friction T-HUB (tapered roller) unit bearing, along with numerous other new products

● NSK’s booth will also display products for e-Bikes as mobility solutions that go beyond the scope of automobiles

NSK Booth

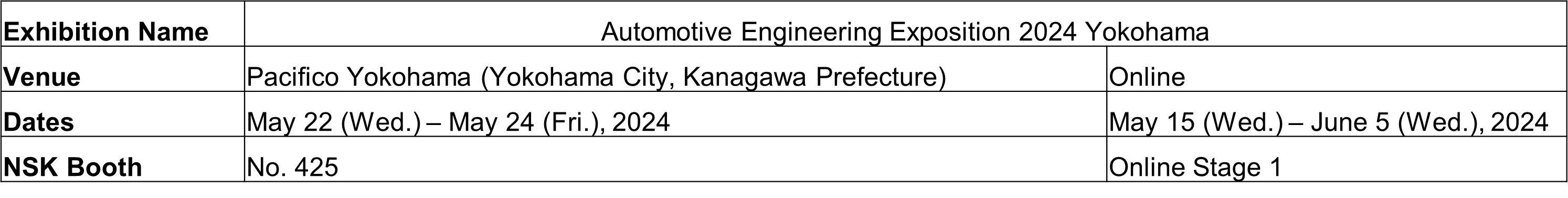

NSK Ltd. will exhibit at the Automotive Engineering Exposition 2024 Yokohama, to be held at Pacifico Yokohama from May 22 to 24, 2024.

NSK’s Booth Concept: “Mobilizing Tomorrow Today: Changing Cars, Changing the Future”

The automotive industry is undergoing a once-in-a-century transformation, with technological diversification and innovation advancing as electric vehicles (EVs) and hybrid electric vehicles (HEVs) become more prevalent.

At this exhibition, NSK will display a wide range of products, from machinery parts to unit solutions, that contribute to the electrification of automobiles’ three major functions: “Driving”, “Steering”, and “Braking”. Through these exhibits, NSK will also showcase how it is helping to realize a carbon-neutral society.

The main exhibits will use a car mock-up to represent NSK’s vision of future vehicles. Cutaway models and other visual aids will demonstrate how NSK’s products are utilized. The functions of these products will be presented through various means, including dynamic moving displays and hands-on exhibits.

NSK will continue to meet the diverse needs of society and lead the world’s mobility technology.

Main Exhibits

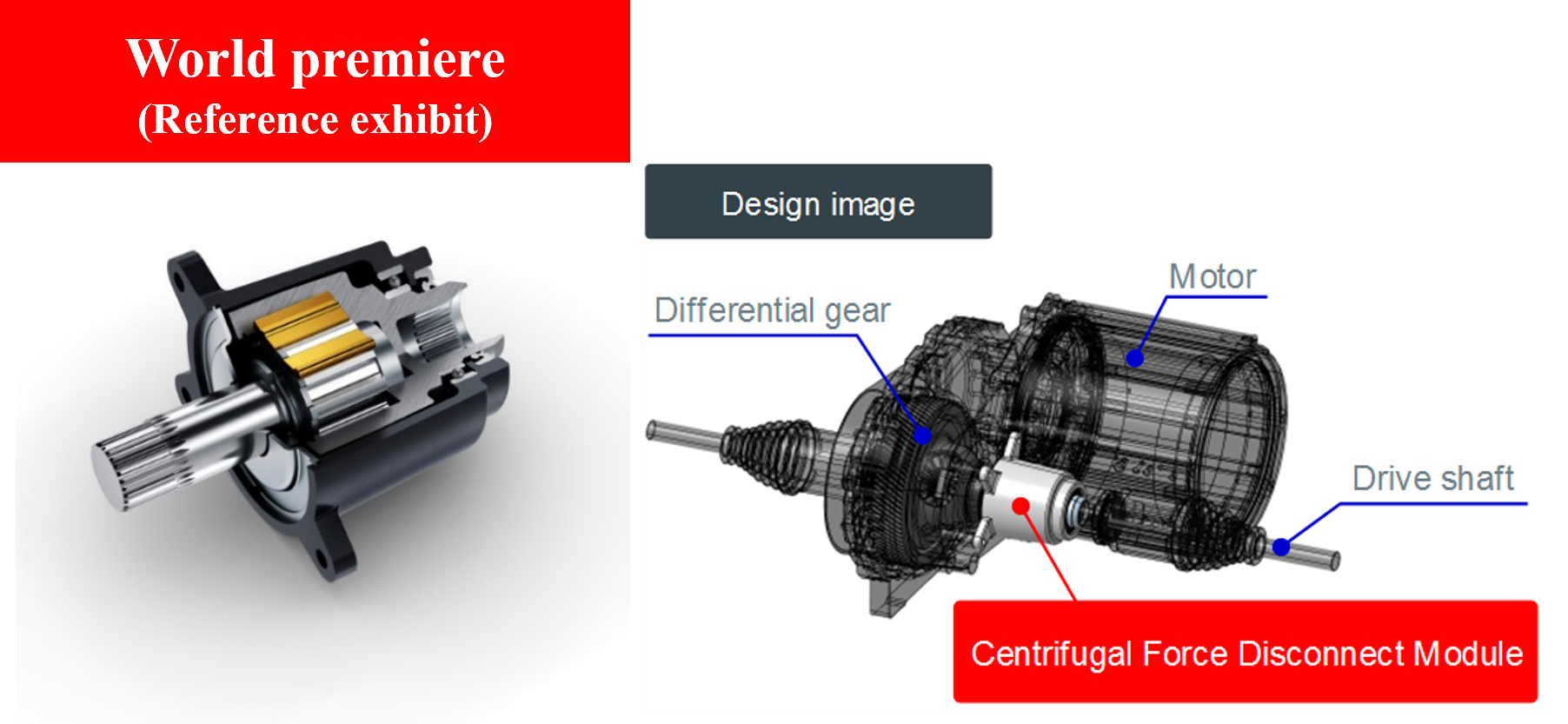

Driving: Centrifugal Force Disconnect Module

Features

1) Simple structure for easy installation in existing eAxle (compact, small installation space)

2) No need for a switching actuator due to the centrifugal disconnect mechanism

3) Achieves high driving efficiency through drive shaft disconnection*

* Disconnects the eAxle and drive shaft, removing drag torque losses by the ring gear and the traction motor with no rotation.

Driving: Ultra-Low Friction T-HUB (Tapered Roller) Unit Bearing (Hands-on Exhibit)

Features

1) Unit bearing that contributes to low friction and weight reduction in electric vehicles

2) Exhibit showing the current model (generation 2.5) and a new product under development with improvements (3rd generation)

Improvements: Reduced preload range and incorporation of design specifications cultivated in ball hubs for low friction

3) The hands-on exhibit at the booth will demonstrate the difference in rotational torque between the current and new products.

Driving: Magnetostrictive Torque Sensor (reference exhibit)

Features

1) Non-contact torque sensor capable of detecting shaft torque

2) Exhibit showing the 3rd generation model, which is more compact and cost-effective compared to the current model

3) Utilizes torque information for system control, leading to extended driving range, improved safety, and enhanced ride comfort

4) The hands-on exhibit at the booth will demonstrate torque measurement, allowing visitors to understand the sensing process.

Steering: High Power and Lightweight Column Type Electric Power Steering (launched fall 2023)

Features

1) High power column type EPS applicable up to C-segment vehicles, including electric vehicles with relatively heavy front axle load

2) Achieves a 10% increase in assist force with a compact, high-torque motor and a 5% weight reduction in the system

3) Realizes smooth handling with low noise and vibration by adopting a next-generation speed reduction mechanism

Other Exhibits

• Driving: Seamless 2-speed eAxle Concept, power flow switching device (PFSD), centrifugal force pawl clutch (CePaC), parallel 3-axis type transaxle unit mock-up, planetary type transaxle unit mockup, conductive brush, electrical bypass plate, R-T/G clutch [roller type torque gate clutch]

• Steering: Dual pinion type electric power steering, locking clutch

• Braking: Ball screw for electric hydraulic brake system

• Mobility-related: Product lineup for e-bike drive units

Exhibition Overview

Official Website:Automotive Engineering Exposition 2024 Yokohama (jsae.or.jp)

About NSK

NSK began its journey manufacturing the first bearings in Japan in 1916, and has since developed into a global organization researching, designing, and manufacturing Motion & Control™ solutions essential for mobility and industrial applications. NSK is the top supplier of bearings in Japan and is the third largest supplier in the world by market share.

Our responsive products and technologies enhance automotive performance and industrial productivity while reducing energy consumption to unprecedented low levels. In the early 1960s, we set our sights outside Japan and have established over 200 business locations in 31 countries alongside a vast network of joint ventures and partnerships in all corners of the world.