NSK Ltd.

Corporate Communications Department

NSK Expands Condition Monitoring Solution Supported by NSK’s Expert Diagnostic Engineers

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) announced the expansion of its condition monitoring solution powered by advanced diagnostic AI and supported by NSK’s experienced equipment diagnostic experts, leveraging the company’s diagnostic technologies cultivated in the monitoring of critical infrastructures. NSK will make this enhanced solution available starting in October 2024.

1. The Current Environment and Expectations Surrounding Condition Monitoring

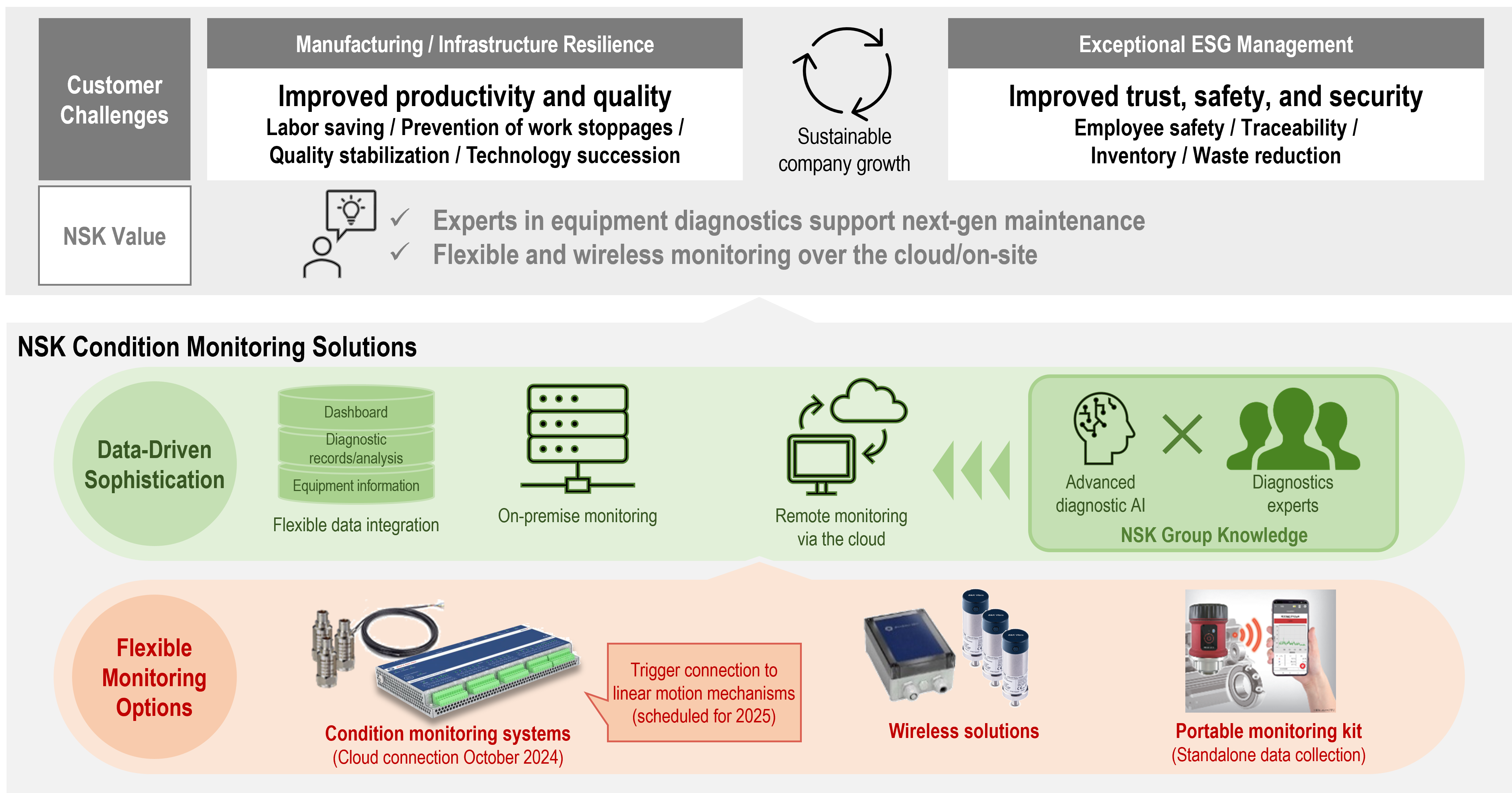

In recent years, there has been a growing need for further improvements in production efficiency and quality, particularly in the manufacturing and infrastructure sectors. At the same time, the importance of further ensuring safety, security, and traceability has increased from the perspective of ESG management.

In this context, there has been a surge in the implementation of condition monitoring solutions, not only in critical infrastructures such as wind turbines and petrochemical plants but also in general industrial machinery, including steel, paper, and automotive manufacturing lines where NSK bearings are used. The high expectations surrounding IoT and digital transformation have also added to this momentum.

Customer challenges and the value NSK provides via condition monitoring solutions (overall image)

2. NSK’s Initiatives to Date and the Current Expansion

Through Brüel & Kjær Vibro, a Germany-based company that is now a member of the NSK Group, NSK has been providing various remote monitoring services based on the extensive diagnostic experience and advanced diagnostic technologies that Brüel & Kjær Vibro has cultivated in critical infrastructure facilities such as wind turbines and petrochemical plants. Since January 2024, NSK has started selling in Japan a condition monitoring solution that combines a wireless condition monitoring system easy to install on machinery and cloud services for companies in the general industrial machinery industry, particularly those new to condition monitoring.

Starting in October 2024, cloud service connectivity will be also made available for the conventional wired-type condition monitoring system. This will enable NSK to provide a condition monitoring solution combining advanced diagnostic AI and diagnostic experts for customers seeking more advanced condition monitoring in general industrial machinery. Furthermore, in 2025, NSK plans to implement a trigger function in the same system to support complex machining processes involving a combination of rotary and linear mechanisms. This will enable condition monitoring for machining and assembly equipment such as machine tools.

As part of efforts to achieve carbon neutrality, NSK is working to provide solutions through the PLM* model, which includes maintenance, repair, and disposal of equipment used in facilities with NSK products. Condition monitoring solutions are indispensable for realizing this goal. NSK will continue to develop technologies toward proposing this new value by linking with conventional products such as rolling bearings and technical services.

* PLM: Product Lifecycle Management. NSK is working to strengthen its service provision system throughout the product lifecycle, including equipment maintenance and repair after product sales.

For more details on NSK's initiatives to achieve carbon neutrality, please refer to the NSK Report.

NSK will exhibit this solution at JIMTOF 2024 (the 32nd Japan International Machine Tool Fair), to be held at Tokyo Big Sight from November 5 to 10, 2024.

About NSK

NSK produced the first bearings in Japan in 1916 and over the past 100 years, it has supported the development of industries worldwide by creating various innovative products and technologies in bearings, automotive parts, and precision machinery. Since the early 1960s, the company has expanded overseas and now has operations in about 30 countries. It ranks third in the world in the field of bearings and leads the world in ball screws, electric power steering, and other products.

■ Reference Press Releases

・ March 2021

・ September 2023

・ February 2024

■ Product Information