NSK Ltd.

Corporate Communications Department

NSK Develops 7th Generation Low-Friction Tapered Roller Bearings

Helping to improve fuel/electricity efficiency in all forms of mobility: ICE, HEV, PHEV, and EV

● Reduces rolling friction by optimizing the number of rollers

● Improves fuel/electricity consumption across the entire range of automobile speeds by achieving an average 20% reduction in friction over the entire rotation speed range

● New optimization technique for the number of rollers also applied to existing models of low-friction tapered roller bearings

● NSK aims to achieve annual sales of 15.0 billion yen by 2030

NSK Ltd. has developed its 7th generation of low-friction tapered roller bearings. This product can help to increase vehicle range through improved fuel/electricity consumption achieved by reducing friction by an average 20% over the entire rotation speed range. NSK aims to achieve annual sales of 15.0 billion yen by 2030 for this product, including existing models.

New Product

1. Background

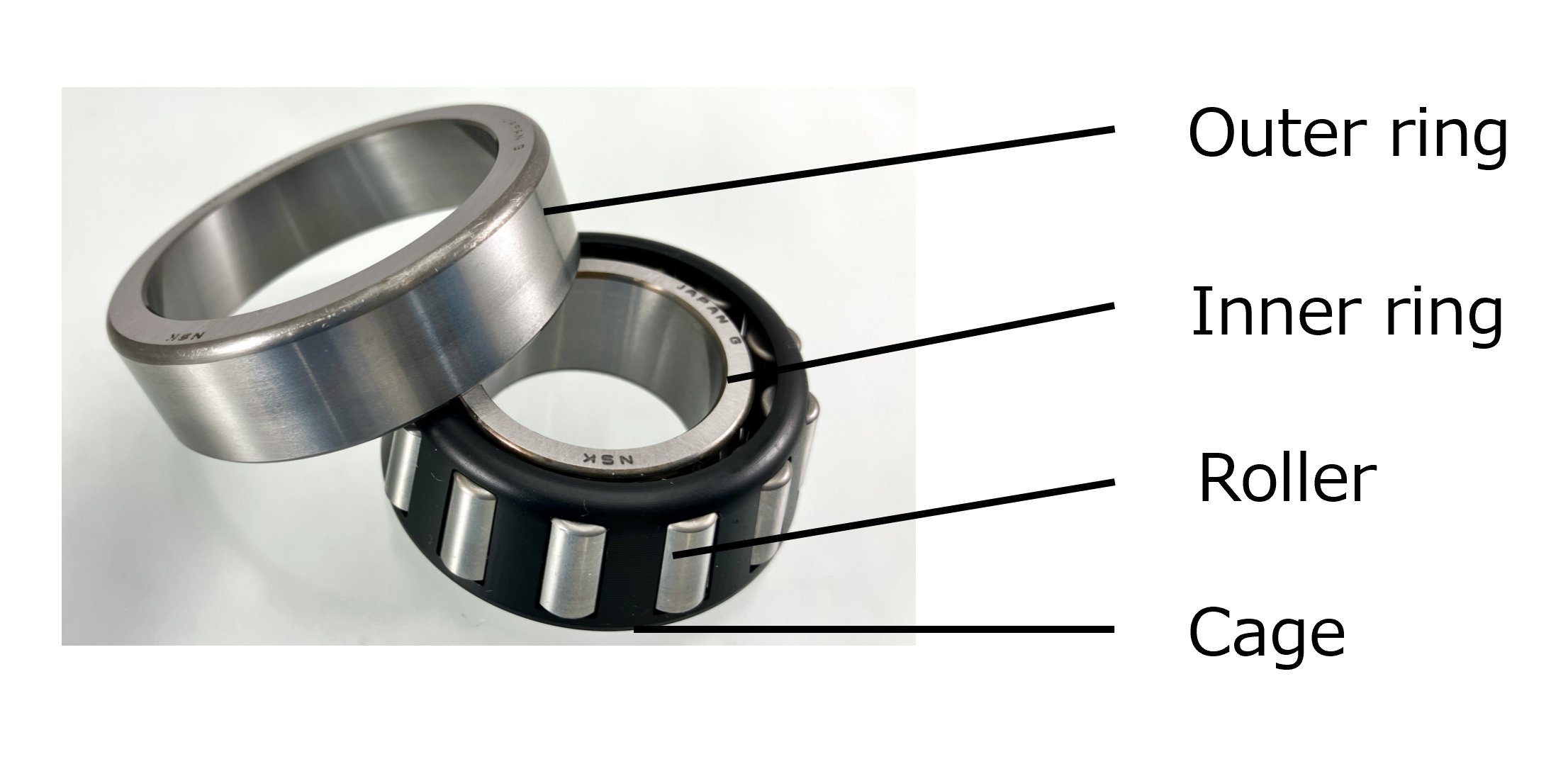

Tapered roller bearings are frequently used when there are low-rotation speed, high-load conditions on the tire side. Therefore, reducing the amount of friction in the roller bearings can help to increase the efficiency of the power train unit.

Position of Tapered Roller Bearings in a Transmission and eAxle

Since around 1980, NSK has used various methods to decrease friction in tapered roller bearings. In recent years, the rapid advance of automobile electrification in pursuit of a decarbonized society has increased the need to reduce friction. Moreover, Japan's adoption in 2017 of the WLTC1 (a standard international method for measuring fuel economy), has made it necessary to further improve fuel economy. Therefore, tapered roller bearings also need to deliver low friction across the entire rotation speed range.

1 WLTC: Worldwide harmonized Light vehicles Test Cycles, an international method for measuring fuel economy, which began to be adopted in Japan by the Ministry of Land, Infrastructure, Transport and Tourism in 2017. Under the previous method of determining fuel economy values (JC08 cycle), the average fuel consumption was measured as an average over the entire range of low to high vehicle speeds. However, under the WLTC cycle, it is measured at each vehicle speed: in the city, in the suburbs, and on highways.

2. Features

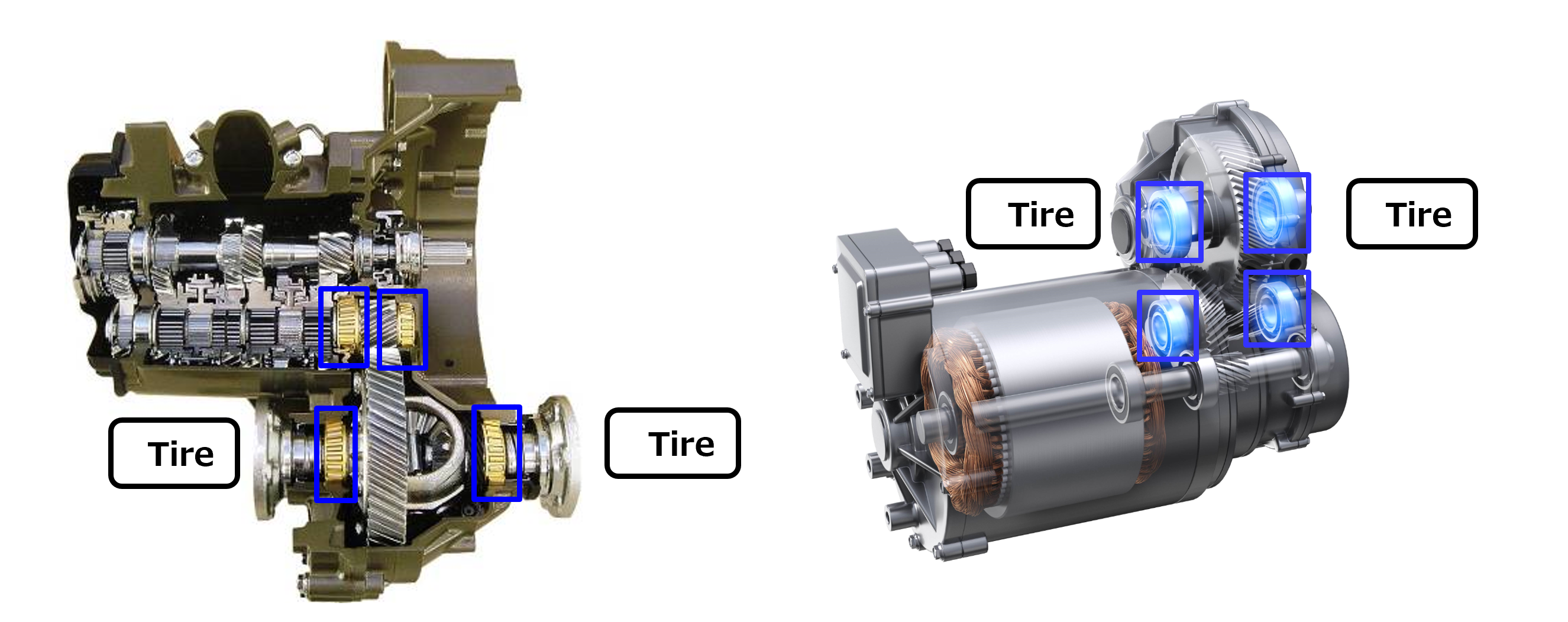

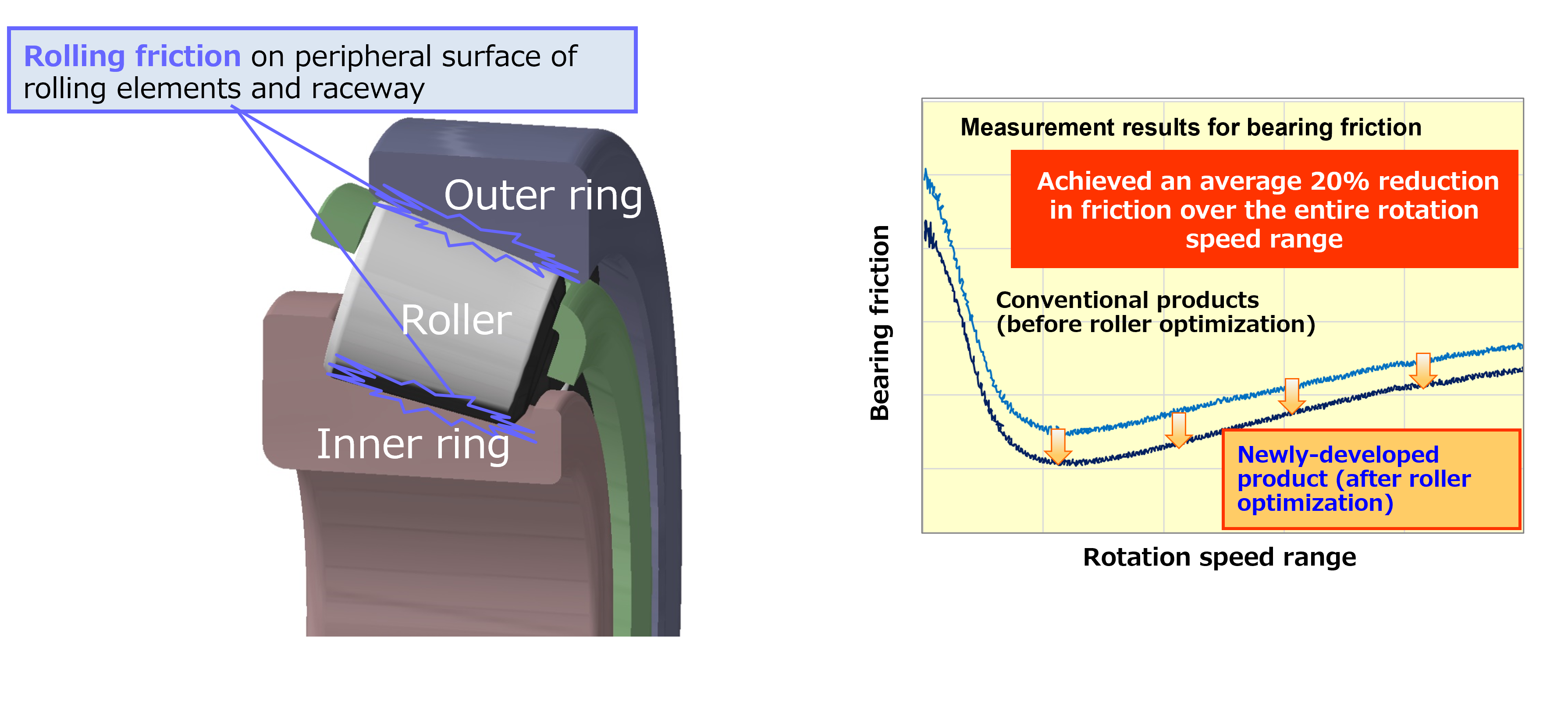

1) Optimization of the number of rollers reduces rolling friction, achieving an average 20% reduction in friction over the entire rotation speed range

Bearing Rolling Friction Bearing Friction for Conventional Products vs.

Newly Developed Product

2) This new specification can be produced using existing facilities, and NSK plans to offer it to customers without delay in order to introduce it to the market as soon as possible.

3) NSK is also applying the new optimization technique for the number of rollers to existing models of low-friction tapered roller bearings.

3.Technology

1) Optimizes the number of rollers in tapered roller bearings by focusing on service life

Tapered roller bearings have been found to be very durable against contamination, and to have a superior service life. Performing new tests, NSK confirmed their actual service life to be even longer than the calculated service life.

2) Resolves issues associated with optimizing the number of rollers

NSK has years of expertise related to special crowning technology and cages for lean lubrication conditions to solve problems, such as excessive surface pressure and seizure at the ends of the rollers, and has leveraged this expertise to optimize the number of rollers.

About NSK

NSK began its journey manufacturing the first bearings in Japan in 1916, and has since developed into a global organization researching, designing, and manufacturing Motion & Control™ solutions essential for mobility and industrial applications. NSK is the top supplier of bearings in Japan and is the third largest supplier in the world by market share.

Our responsive products and technologies enhance automotive performance and industrial productivity while reducing energy consumption to unprecedented low levels. In the early 1960s, we set our sights outside Japan and have established over 200 business locations in 31 countries alongside a vast network of joint ventures and partnerships in all corners of the world.