- NSK developed world's first high-accuracy onsite method to rapidly diagnosis the remaining life of lubricant grease; to be provided as a mobile app

- Contributes to industry trend of switching to condition-based maintenance (from conventional time-based maintenance)

- Relieves customer pain points related to redundant costs in grease inspection and replenishment

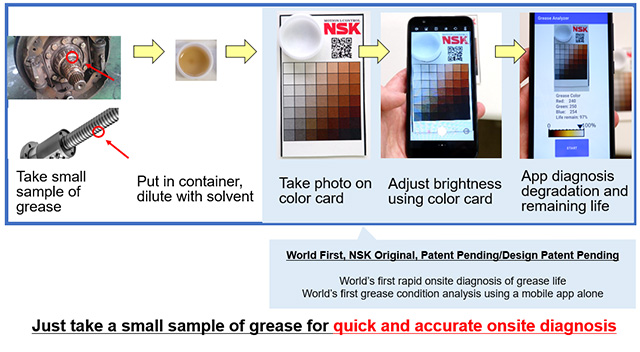

NSK is developing a mobile app applying its newly developed method to rapidly diagnose the remaining life of lubricant grease. The app will enable rapid, high-accuracy onsite analysis of grease condition.

NSK is seeking customer input and feedback on the system to accurately reflect customer needs in the app and aiming to officially launch the service in fiscal 2025. This service will contribute to reduced grease inspection and grease replenishment costs and the implementation of condition-based maintenance.

NSK will exhibit this technology at IPF Japan 2023, an international plastics exhibition to be held at Makuhari Messe from November 28 to December 2, 2023.