NSK Ltd. announced that it will exhibit its products and technologies at TIMTOS x TMTS 2022, to be held at Taiwan Taipei from February 21 - February 26 , 2022.

Summary of the Exhibition and NSK Objectives to participate in exhibition, concept, market situation.

Our purpose is to let NSK brand image up in industry 4.0 and machine tool sector.

Products to exhibit and key product highlight with some explanations

Major Exhibits

- 1. ROBUSTDYNA™ High Load Capacity Ultra-High Speed Angular Contact Ball Bearings

-

- Design optimizations increased machining load rating by 15% and dynamic load rating by 40% (equivalent to tripling fatigue life). Also increased static load rating by 30% and reduced the risk of damage from collision or impact

- Enables highly versatile machining by delivering excellent performance across both roughing and finishing. Made with SHX steel for 3 million dmN ultra high speed performance despite also being capable of performing heavy cutting.

- 2. Ultra High Speed Angular Contact Ball Bearings with SURSAVE™ Cage

-

- Compared with conventional products reduced NRRO (Non-Repeatable RunOut) by 50% at high speeds, and torque by 20% for low heat generation.

- Robust series BNR and BER types are now available in a wide range of sizes (30-110 mm bore diameter).

- P3W tolerance class (tighter width tolerance than ISO Class 2 and equivalent rotational accuracy) for extremely low deviation of bearing width dimension. The series offers high rotational accuracy as a standard feature.

- 3. High-Reliability Single-Row Cylindrical Roller Bearings

-

- Optimized guidance of the rolling elements and improved pocket shape expels excess lubricant more effectively. Significantly reduces grease running-in time. Improved heat generation characteristics when using oil lubrication at low speeds.

- Optimized pocket contouring to reduce stress on the cage when rolling elements bearing load contact the cage, thereby improving cage durability.

- 4. Ball Screw Technology of Reducing Machine Tool Quadrant Glitches

-

- Reduced frictional variation when the ball screw reverses direction of motion, thereby reducing quadrant glitches (motion errors) in machine tools.

- The second spike cannot be fully compensated for in function of a servo controller, but ball screw NSK technology eliminates the second peak and reduces the first peak.

- Achieves a higher quality finish on the workpiece surface and shortens the finishing process, ultimately contributing to energy savings and increased machine tool productivity.

* exhibiting production is dummy.

- 5. High Durability Precision Ball Screw

-

- Enhanced oil film formation prevents metal-on-metal contact thereby significantly improving wear resistance. This is especially effective under conditions in which it is difficult for an oil film to form, such as low-speed short-stroke machining work.

- Maintenance-free for longer periods due to ball screw accuracy life being extended. Achieve highly reliable and stable operations.

- Reduces machinery energy consumption due to enhanced oil film formation reducing dynamic friction torque by up to 40%.

* exhibiting production is dummy.

- 6. Long Life NSK Linear Guides™ DH Series, DS Series

-

- Contributes to improving machinery reliability with double the fatigue life achieved with NSK's TF Technology.

- Complete interchangeability with NH, NS Series (standard series), easily switch to DH, DS Series.

- Wide range of including seals, lubrication units, and other options and configurations ideal for many applications.

* exhibiting production is dummy.

- 7. NSK K1-L Lubrication unit for NSK Linear Guides™

-

- About double the service life compared to the original NSK K1. Increased lubrication capability for long-term maintenance-free operation.

- Reduced dynamic friction force by about 20% when the slider is moving, which contributes to energy savings in machinery operation.

- Now available with casing to prevent ingress of dust and contamination.

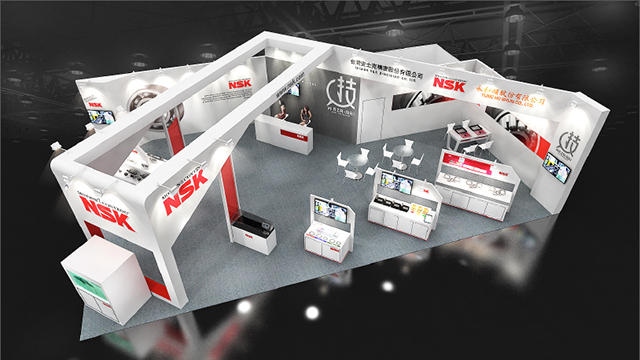

Overview appearance of NSK booth

Overview of Exhibition

| Name of Exhibition |

TIMTOS x TMTS 2022 |

| Organizer |

- Taiwan External Trade Development Council(TAITRA)

- Taiwan Association of Machinery Industry (TAMI)

- Taiwan Machine Tool & Accessory Builders' Association (TMBA)

|

| Dates |

February 21 - February 26 , 2022 |

| Venue |

Taipei Nangang Exhibition Center, Hall 1 & 2 |

| NSK Booth No. |

TAIPEI NANGANG Exhibition Center, Hall 2 4F S0824 |

| Official website |

https://www.timtos.com.tw/en/

|

About NSK

NSK began its journey manufacturing the first bearings in Japan in 1916, and has since developed into a global organization researching, designing, and manufacturing Motion & Control™ solutions essential for mobility and industrial applications. NSK is the top supplier of bearings in Japan and is the third largest supplier in the world by market share.

Our responsive products and technologies enhance automotive performance and industrial productivity while reducing energy consumption to unprecedented low levels. In the early 1960s, we set our sights outside Japan and have established over 200 business locations in 30 countries alongside a vast network of joint ventures and partnerships in all corners of the world.

NSK Corporate Philosophy

NSK contributes to a safer, smoother society and helps protect the global environment through its innovative technology integrating Motion & Control. As a truly international enterprise, we are working across national boundaries to improve relationships between people throughout the world.

NSK Vision 2026: Setting the Future in Motion

Contributing to society while growing as a company—NSK will set the future in motion by creating new value beyond the world's expectations.