NSK's First Endurance Test Unit for Electric Injection Molding Machine Ball Screws Recognized as Tribology Heritage

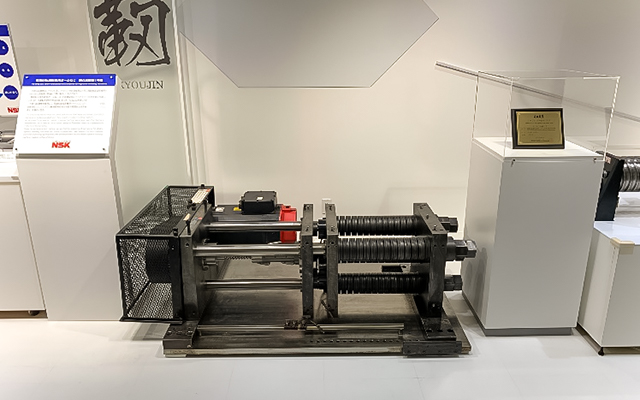

NSK Ltd.'s first Endurance Test Unit for Electric Injection Molding Machine Ball Screws was recognized as Tribology Heritage1 by the Japanese Society of Tribologists2 for its contribution to the advancement of tribology technology.

In injection molding machines, a hydraulic motor was generally used for the feed system that pushes the plastic resin into the mold due to the heavy load. However, from the 1980s onward, the need for electrification has been increasing for its energy conservation and environmental protection aspects. The increased control over resin injection, improved operability, and ease of maintenance offered by electric motors further accelerated the shift away from hydraulic technology.

Since the ball screws used in electric molding machine motors are operated in short strokes and take on an extremely heavy load, maximizing the ball screw's endurance, including the endurance of the lubricant, was a major challenge. This test unit was created in 1990 with the aim of increasing the endurance of ball screws, making it possible to evaluate and improve prototypes. The unit went on to make contributions to the enhancement of electric molding machine performance and the advancement of the electrification of industrial machinery.

Click here for more information on products for electric injection molding machines.

NSK will continue to leverage its world-leading technical prowess to realize a safe, comfortable, and environmentally-friendly society, and further the advancement of industry.

1: The Japanese Society of Tribologists was established in 1956 with the aim of improving technology related to tribology (the science and technology of interacting surfaces in relative motion).

2: Tribology Heritage is an award that aims to identify and preserve technology that has made significant contributions to tribology throughout the history of the development of science and technology in the field. NSK's first roller bearing design drawing was the first technological artifact to be recognized as Tribology Heritage.

Japanese Society of Tribologists website:

https://www.tribology.jp/indexe.htm

![]()