NSK Ltd. will be exhibiting for the first time at the Flying Car Technology Expo, to be held at Tokyo Big Sight from November 4-6, 2020.

The rapid pace of development has been increasing expectations for the wide-scale commercialization of flying cars as an alternative means of transportation, to reduce congestion in urban areas, and ease access to mountainous areas and remote islands. Demand for unmanned drones is also expected in aerial photography and surveillance, light cargo transport, agriculture, disaster rescue, and hobby applications.

The Ministry of Economy, Trade and Industry (METI) and the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) have established the Public-Private Partnership Council for a Revolution in Air Mobility with the aim of fostering the development of flying cars in Japan. Companies have been developing prototypes in accordance with the road map presented by the Council, which emphasizes safety and reliability as an aircraft, but also quieter and longer range operation capabilities.

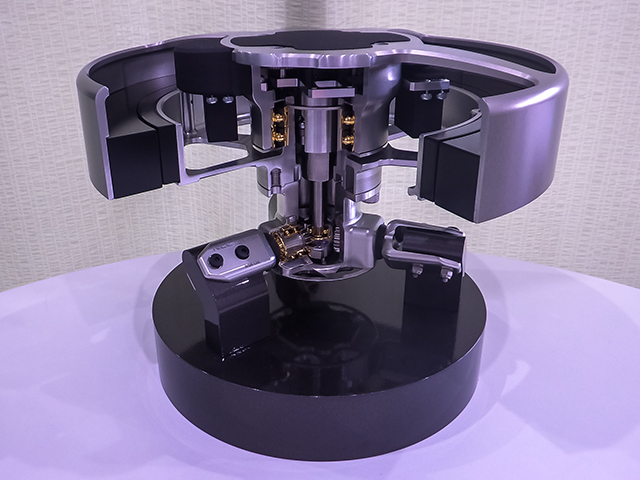

NSK has developed a “motor hub with variable-pitch propeller mechanism,” which supports the rotation of the propeller and adjusts the tilt of the blades to change the direction of propulsive force and lift. Due to its role in these vital functions, the motor hub is one of the most important components of a flying car. Of course, the motor hub with variable-pitch propeller mechanism employs bearings and ball screws made by NSK.

At NSK’s booth, on display is a complete motor hub unit that was used in a successful flight test last year. The unit has a cutaway so you can examine the internal structure in detail. In addition, NSK will also exhibit bearings for motors that are ideal for drones and bearings used in the rotating mechanism to adjust the angle of drone cameras.

NSK began its journey manufacturing the first bearings in Japan in 1916, and has since developed into a global organization researching, designing, and manufacturing Motion & Control™ solutions essential for mobility and industrial applications, often leading the pack with new products and innovations. NSK will continue to contribute to the development of new modes of mobility such as flying cars by drawing our strengths in our Four Core Technologies Plus One: Tribology, Materials, Numerical Simulation, Mechatronics, and Manufacturing Engineering.