NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President & CEO: Toshihiro Uchiyama) has inaugurated a second line producing ball screw units for electric-hydraulic brakes. Global demand for the ball screw units is rapidly increasing with regulators mandating new vehicles be equipped with automatic emergency braking systems.

NSK started production of the units in March 2018 at its Saitama Plant. The newly inaugurated line, at Akagi Plant (NSK Steering Systems Co., Ltd.), began production in January 2020.

The automotive industry is set to revolutionize automotive safety over the next few years. Regulators around the world have mandated new vehicles be equipped with automatic emergency brake systems. The requirements are coming into effect around 2021-2022 in Japan, the United States, and the European Union.

Automatic emergency brake systems help prevent accidents by scanning the road ahead of the vehicle and engaging the brakes to avoid potential collisions. The system automatically brakes if approaching another vehicle or obstacle at a speed that could result in an accident.

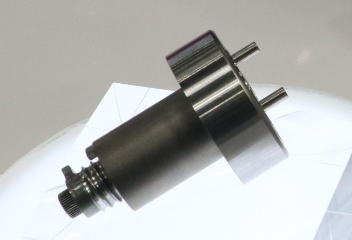

NSK began mass production of ball screw units for electric-hydraulic brake systems in March 2018. The unit is a compact and lightweight combination of high reliability ball screw and support bearing made possible by NSK's world-class ball screw technology and over a century of expertise in bearings.

The units are already in consumer vehicles on the road, and automakers are rolling out implementation to other models. NSK established the new line to respond to rapidly growing demand. NSK is also considering establishing additional production sites outside Japan, and is aiming to produce 10 million units a year globally by 2026. The company is investing around 10 billion yen to expand ball screw production capacity.