NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) will exhibit its products and technologies at the 29th Japan International Machine Tool Fair (JIMTOF), to be held at Tokyo Big Site from November 1-6, 2018.

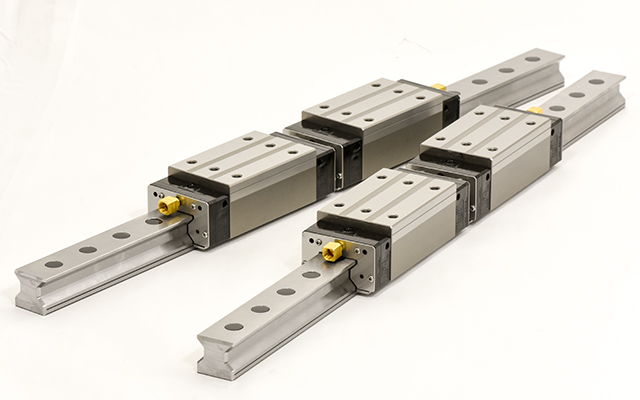

Machine tools are the backbone of industry, serving as essential infrastructure to make components for other machines. NSK is proud to be the only major company to research, develop, and manufacture precision bearings, balls screws, linear guides, and spindles, the four core components of machine tools.

Drawing on our vast expertise in the sector, we are excited to present a wide range of new and future technologies to boost machining performance, achieve energy savings, increase productivity, enable easier automation, and visualize component and system health. NSK's world class solutions are ready to keep your business competitive with the highest level of reliability and extensive features designed specifically to meet the needs of machine tool customers.