NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) will exhibit new products and technologies for the machine tools industry at EMO Hannover 2017.

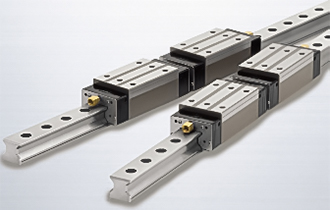

NSK, a world-leading manufacturer of machine tool components, is happy to announce a new product lineup designed specifically for European customers, which aims to exceed the expectations of industry-leading European machine tool manufacturers.

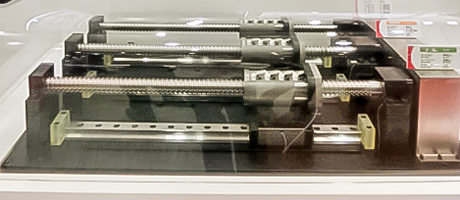

Under the theme “Precisely Forward - NSK Motion Solutions,” NSK will exhibit new products and technologies that contribute to stable operation, precise processing, and higher cycle speeds for this market. As market demand continues to increase, this initiative from NSK represents the acceleration of an effort to release a broader series of technically-advanced, highly-competitive solutions to meet the needs of Industry 4.0 and the rapidly evolving machine tools market. Come to NSK for the most inspired and comprehensive solutions at EMO Hannover 2017.

- Background:

- Last year in April, German and Japanese officials pledged to improve cooperation in the machine tools industry as part of the “Industry 4.0” initiative. Industry 4.0, initially promoted by the German government, aims to draw out the latent potential of industry through effective utilization of connectivity (IoT), the global value chain, and highly flexible production capabilities. This effort for the technological advancement of manufacturing centers has started a revolution, sparking demand for high-variety low-volume production systems to efficiently and cost effectively produce small sets of customized products.