NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed a new ultra-high-speed spindle with grease lubrication for grinding process applications that helps achieve energy savings and a clean environment. This new product improves production efficiency using ultra-high speeds for grinding process machine tool applications, and realizes energy savings and a clean plant environment.

NSK will exhibit this product at JIMTOF 2016, the 28th Japan International Machine Tool Fair, to be held at Tokyo Big Sight (Koto Ward, Tokyo) from Thursday, November 17 to Tuesday, November 22, 2016. NSK is targeting 200 million yen in global annual sales of the new product in 2018.

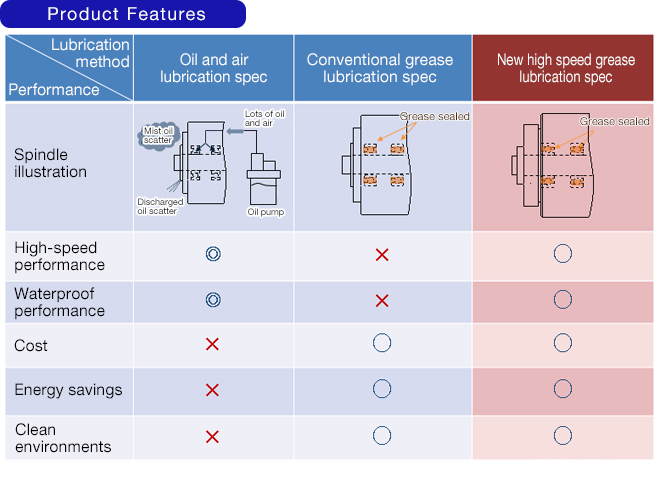

In recent years, there has been a growing need for higher speeds in grinding spindles used in the fabrication of machine tool and automobile components in order to improve production efficiency. Further, there has been a demand for measures to achieve better energy savings and cleaner plant environments. In order to satisfy these needs and demands, it became necessary to switch from the conventional approach of oil and air lubrication to grease lubrication for grinding spindles. However, when it comes to the ultra-high-speeds of grinding spindles (dmn200 x 104 above), grease lubrication poses a challenge in terms of the life of the spindle.

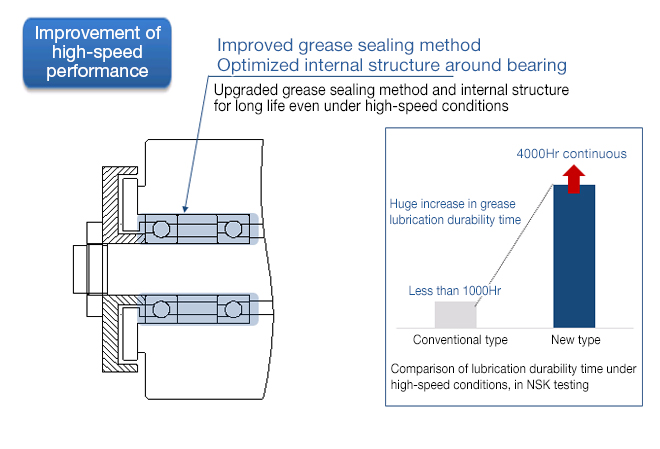

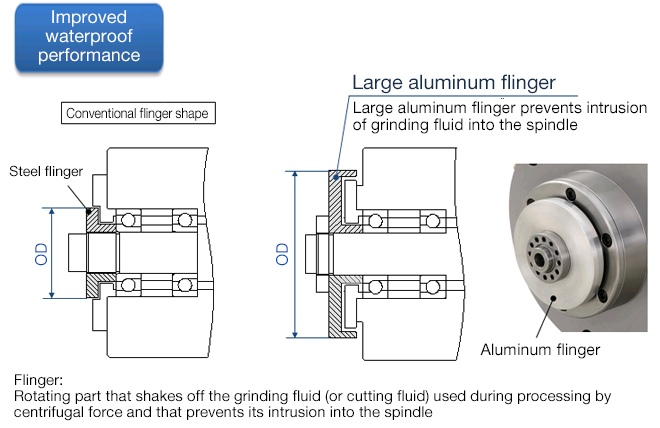

In response to this challenge, NSK improved its grease sealing method and optimized the inner structure of the spindle to achieve ultra-high speeds (dmn200 x 104 above) using grease lubrication. These speeds could only be achieved by oil and air lubrication before. Thus, NSK was able to develop a spindle that leverages the features of grease lubrication: energy savings and a clean environment.