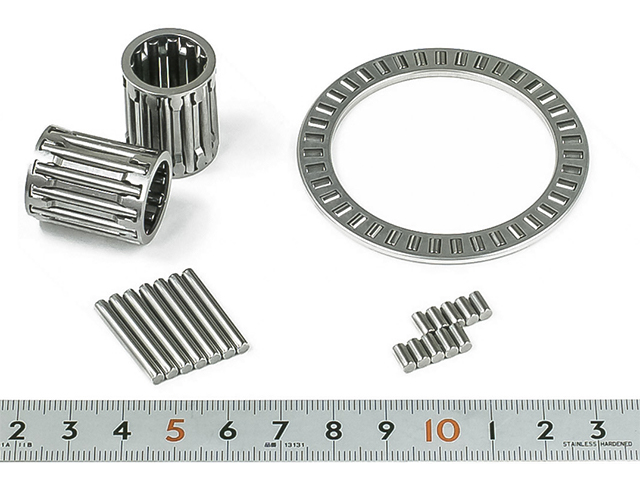

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed super long-life needle roller for automobile transmissions.

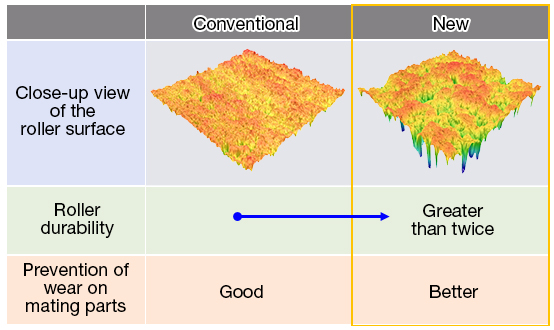

This new needle roller improves the durability of needle roller bearings in sever conditions with insufficient lubrication. It also prevents damage with the mating parts the rollers contact to further improve the reliability of automobiles. NSK is targeting 2.5 billion yen in global annual sales for this product in 2020.

As fuel efficiency regulations have become stricter in recent years, demand for higher fuel efficiency in automobiles has increased around the world. For transmissions, this has meant using lower viscosity lubrication and lesser amounts of lubrication to improve fuel efficiency. Unfortunately, this has made conditions sever for needle bearings due to insufficient lubrication, which in turn has resulted in the need to prevent early damage of needle roller bearings and wear in the mating parts contacted by the rollers.

In response to this, NSK developed super long-life needle roller suited to the sever conditions of insufficient lubrication. These new rollers prevent damage of needle roller bearings and wear on mating parts.

This new roller contributes to higher automobile transmissions efficiency and improved automobile fuel efficiency.