NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it is releasing a high-performance precision ball screw based on new technology designed for machine tool high-performance ball screws that it announced in October 2014. This technology features a huge improvement in ball screw motion control. NSK will launch this new product in October 2015 targeting 2 billion yen in global sales in 2018.

NSK Ltd. will exhibit this product at MECHATRONICS TECHNOLOGY (MECT) JAPAN 2015 to be held at Port Messe Nagoya (Nagoya Int'l Exhibition Hall) in Japan from October 21 to October 24, 2015.

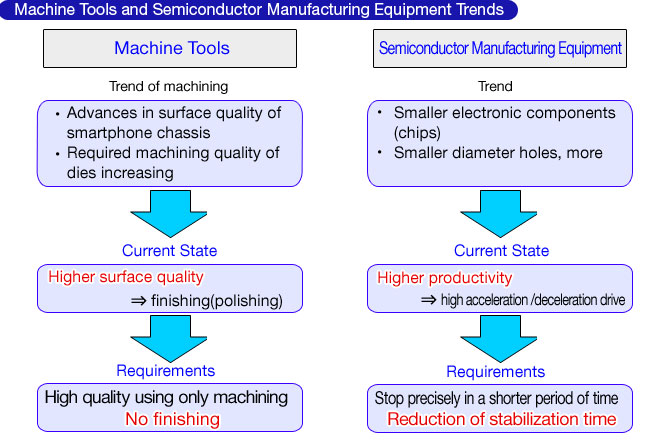

In recent years, there has been a rise in the demand for less motion error in ball screws in order to improve the surface quality of machined components as a result of the increase in the precision of machine tools, such as 5-axis machine tools, as well as an increase in the surface quality of die-fabricated parts.

Likewise, for semiconductor manufacturing equipment, there has been a rise in the demand for higher productivity of printed circuit boards by increasing the fabrication capacity per unit time due to the miniaturization of electronic components such as those used in smart phones.

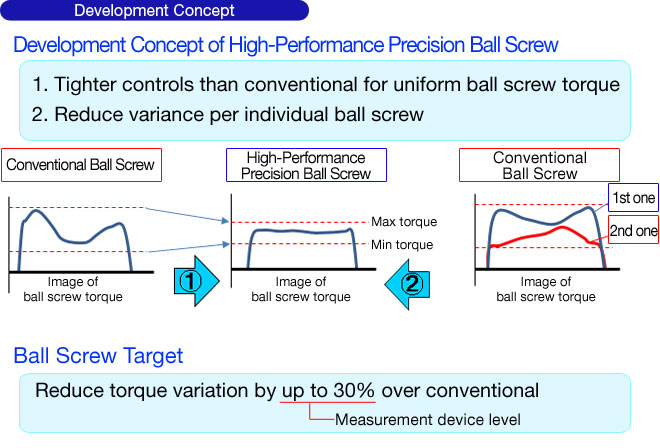

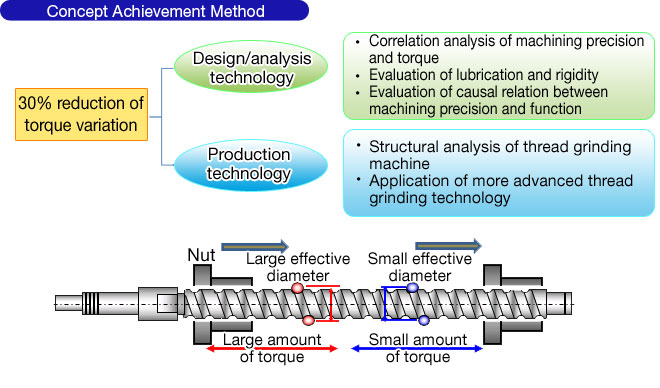

In response to these demands, and driven by advances in its production technology, NSK has released a new high-performance precision ball screw.

Machine tools, semiconductor manufacturing equipment, medical devices, measurement devices, etc.