NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed the world's smallest roller thrust needle bearing for planetary gear mechanisms* for use in automobile multistage automatic transmissions (step AT).

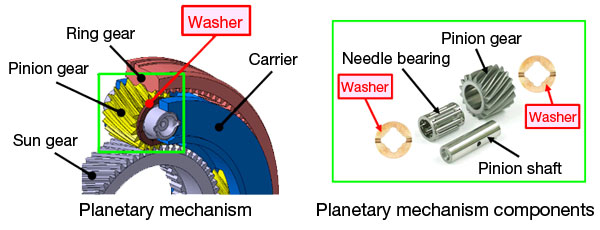

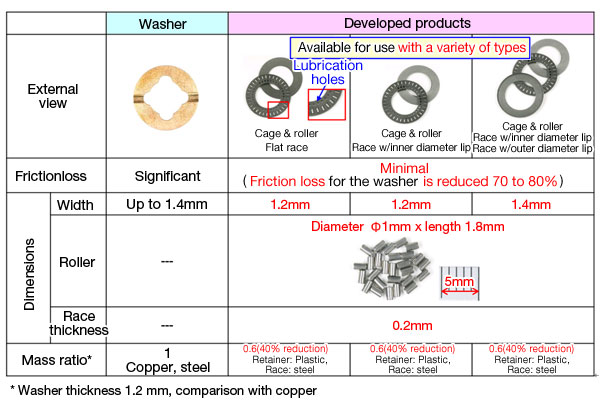

Washers (slide bearings) are used in planetary gear mechanisms for step AT; however, their friction loss reduction became an issue. To solve this, NSK developed the world's smallest roller at a diameter of Φ1 mm x length 1.8 mm, making it possible to replace the washers with thrust needle bearings. This solution significantly reduces friction loss.

NSK is targeting 1.8 billion yen in global annual sales in 2020, enhancing the efficiency of step AT's and thus increasing automobile fuel efficiency.

| * Planetary mechanism: | A reduction mechanism adjusts output speed and torque by utilizing a combination of rotation and revolution movements of multiple gears. |