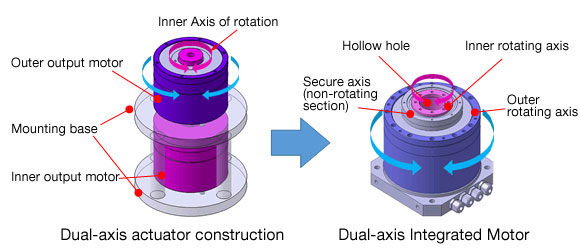

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed a dual-axis integrated motor that is capable of two independent rotary motion outputs.

This product was developed to simplify actuator construction and make it more compact. By applying NSK Megatorque Motor™ technology, a 2.62 million count/rotation high resolving power is achieved. By integrating two axes, wiring for each cable type is simplified, resulting in an advanced actuator and contributing to reduced maintenance.

NSK will exhibit this new product at the International Robot Exhibition 2015, to be held at Tokyo Big Sight (Koto-ku, Tokyo) from Wednesday, December 2 to Saturday, December 5. NSK will search for potential practical applications for this product such as in the robotics market.