Tokyo, Japan, February 18, 2014 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has completely renewed its Monocarrier™ series by making it faster, quieter, longer life, and expanding of compact size.

NSK will commence sales of this series from April of 2014 and is targeting 1 billion yen in increased sales by 2015.

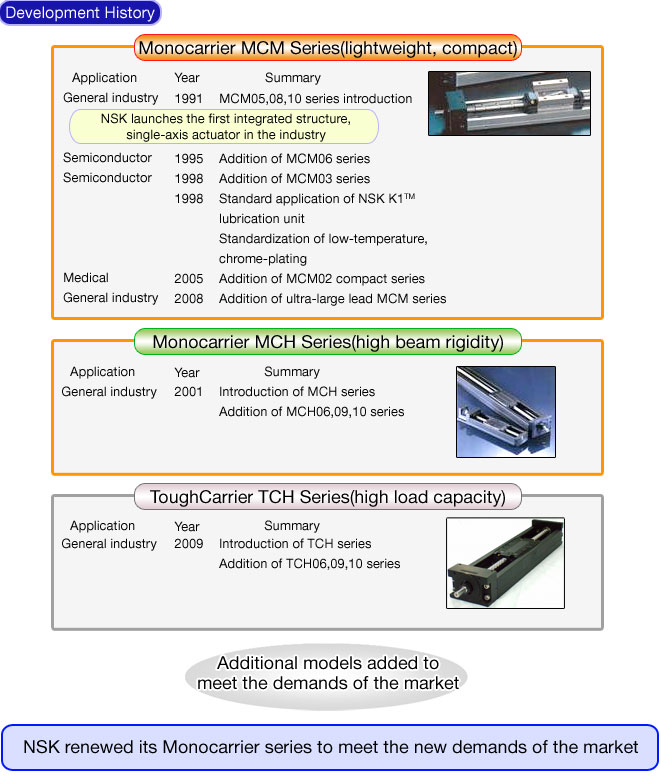

NSK was the first company in the industry to develop lightweight, compact single-axis actuators— Monocarrier MCM series—for various applications such as semiconductor and LCD manufacturing equipment as well as conveyance applications for automobile-related equipment. The Monocarrier series integrated three components—the ball screw, NSK Linear Guide™ and support bearings. NSK introduced this series to the market in 1991, and then in 2001, it introduced Monocarrier MCH series with. Later, in 2009, NSK introduced higher beam rigidity ToughCarrier™, which was capable of ultra-high loads due to the use of as the rollers element of the guide. In this way, NSK has answered the diversified needs of the market.

In recent years, there has been increased demand for even higher levels of productivity and shorter takt times. In addition, there is greater demand for more compact sizes in order to meet the demand for more compact equipment.

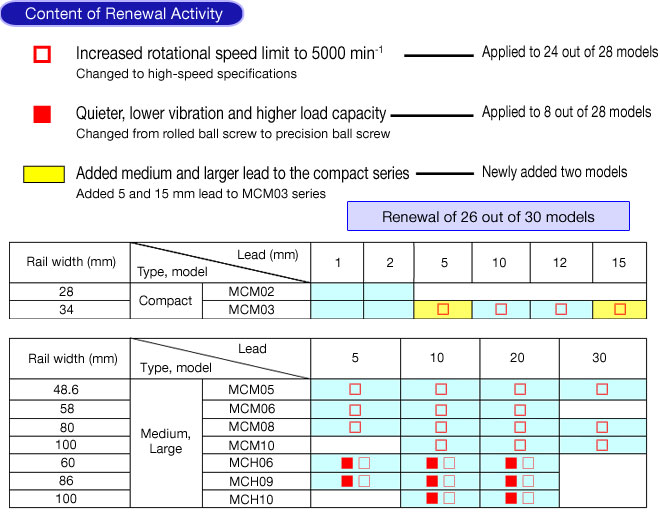

In response to the diversified needs and growing applications for its Monocarrier series, NSK has developed the following superior features for Monocarrier series.

Perfect for semiconductor, LCD, automobile and general industry machine applications.

Increased speed for greater production efficiency.